Method for manufacturing high-strength composite furniture panel material by utilizing moso bamboo fibers

A technology of moso bamboo fiber and high strength, which is applied in the field of furniture panels, can solve the problems of inability to meet consumer demand, easy deformation of furniture panels, and high production costs, and achieve the effects of high toughness, low cost, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

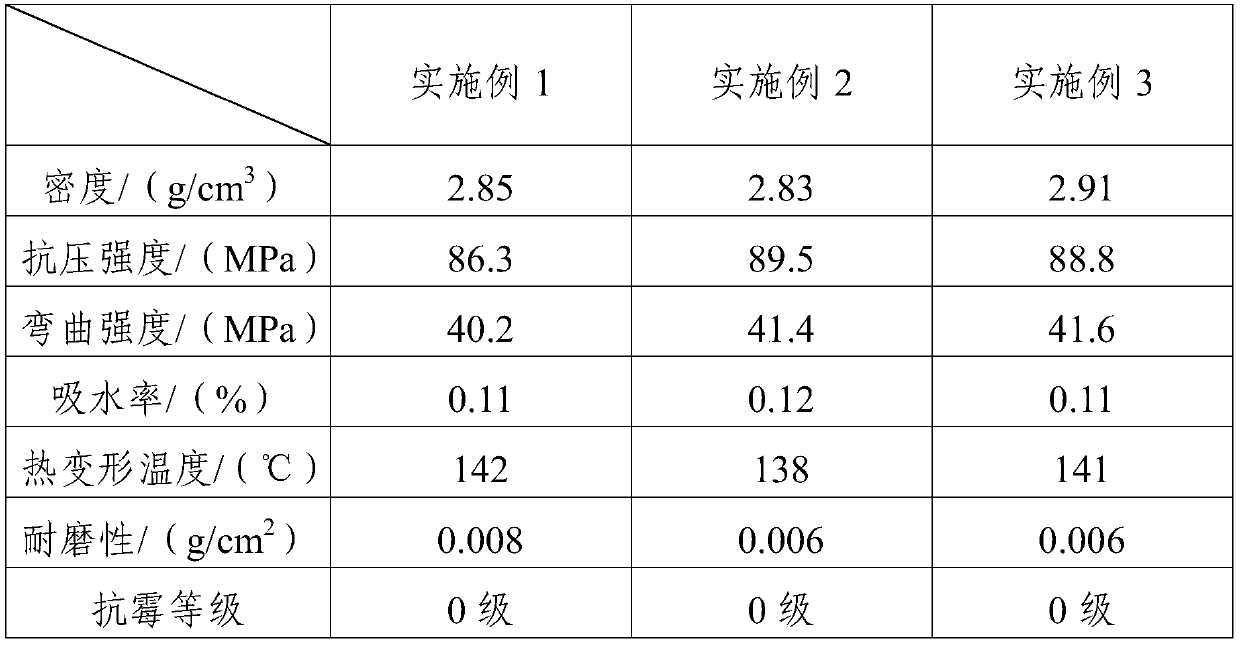

Examples

Embodiment 1

[0029] A kind of method utilizing moso bamboo fiber to make high-strength composite furniture panel material, comprises the following steps:

[0030] (1) After drying the moso bamboo at 55°C, crush it with a pulverizer, immerse the crushed moso bamboo in a sodium hydroxide solution with a mass concentration of 12%, heat up to 80°C, seal and cook for 3.5 hours, remove it, and put it directly into a steam blaster During the process, pressurize to 3MPa, hold the pressure for 130s, blast and release the pressure, and the blasting and pressure relief time is 0.0875s, centrifuge the blasted moso bamboo and blasting black liquor, wash with water until neutral, and then dry to obtain moso bamboo fiber;

[0031] (2) Add moso bamboo fibers into deionized water at 600r / min and stir for 40min, then add disodium edetate and KH-550, treat with ultrasonic vibration for 10min, the power of ultrasonic vibration treatment is 500W, then add nano-calcium carbonate , mixed at 1000r / min and stirred...

Embodiment 2

[0035] A kind of method utilizing moso bamboo fiber to make high-strength composite furniture panel material, comprises the following steps:

[0036] (1) After drying the moso bamboo at 52°C, crush it with a pulverizer, immerse the crushed moso bamboo in a sodium hydroxide solution with a mass concentration of 15%, heat up to 80°C, seal and cook for 4 hours, take it out, and put it directly into a steam blasting machine , pressurize to 3MPa, hold the pressure for 150s, blast and release the pressure, and the blasting and pressure relief time is 0.0875s, centrifuge the blasted bamboo and blasting black liquor, wash to neutral and then dry to obtain the bamboo fiber;

[0037] (2) Add moso bamboo fibers into deionized water at 600r / min and stir for 50min, then add disodium edetate and KH-550, treat with ultrasonic vibration for 8min, the power of ultrasonic vibration treatment is 400W, then add nano-calcium carbonate , mixed at 900r / min and stirred for 25min, filtered out the mos...

Embodiment 3

[0041] A kind of method utilizing moso bamboo fiber to make high-strength composite furniture panel material, comprises the following steps:

[0042] (1) After drying the moso bamboo at 60°C, crush it with a pulverizer, immerse the crushed moso bamboo in a sodium hydroxide solution with a mass concentration of 16%, heat up to 75°C, seal and cook for 5 hours, take it out, and put it directly into a steam blasting machine , pressurize to 3MPa, hold the pressure for 130s, blast and release the pressure, the blasting and pressure relief time is 0.0875s, centrifuge the blasted bamboo and blasting black liquor, wash to neutral and then dry to obtain the bamboo fiber;

[0043] (2) Add moso bamboo fibers into deionized water at 500r / min and stir for 50min, then add disodium edetate and KH-550, treat with ultrasonic vibration for 7min, the power of ultrasonic vibration treatment is 400W, then add nano-calcium carbonate , mixed at 1000r / min and stirred for 25min, filtered out the moso b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com