Main box body of crushing and grinding machine

A main box and grinding machine technology, applied in grain processing, etc., can solve the problems of box heating, sticking to the pot, etc., and achieve the effects of preventing corrosion and aging, increasing surface roughness, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

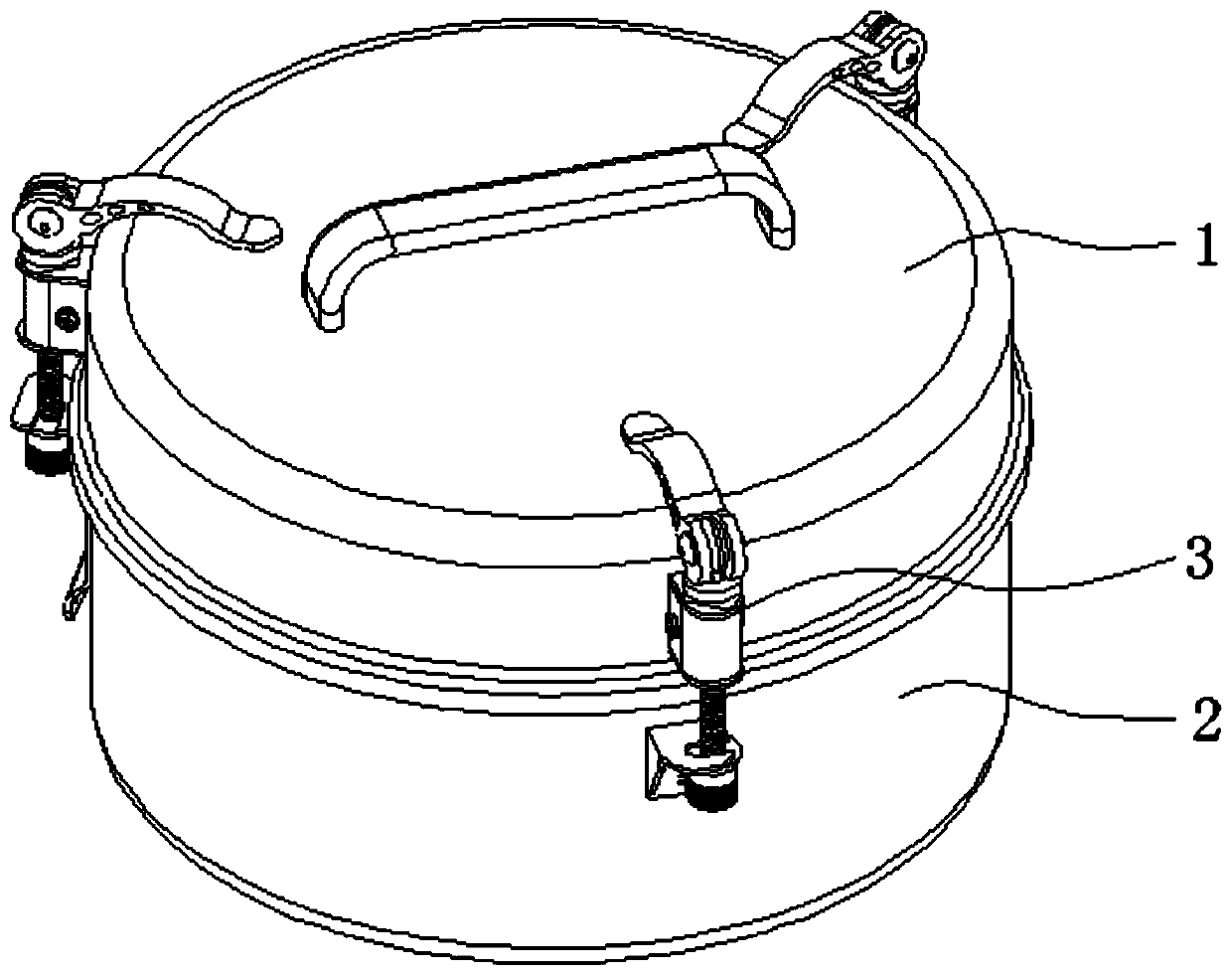

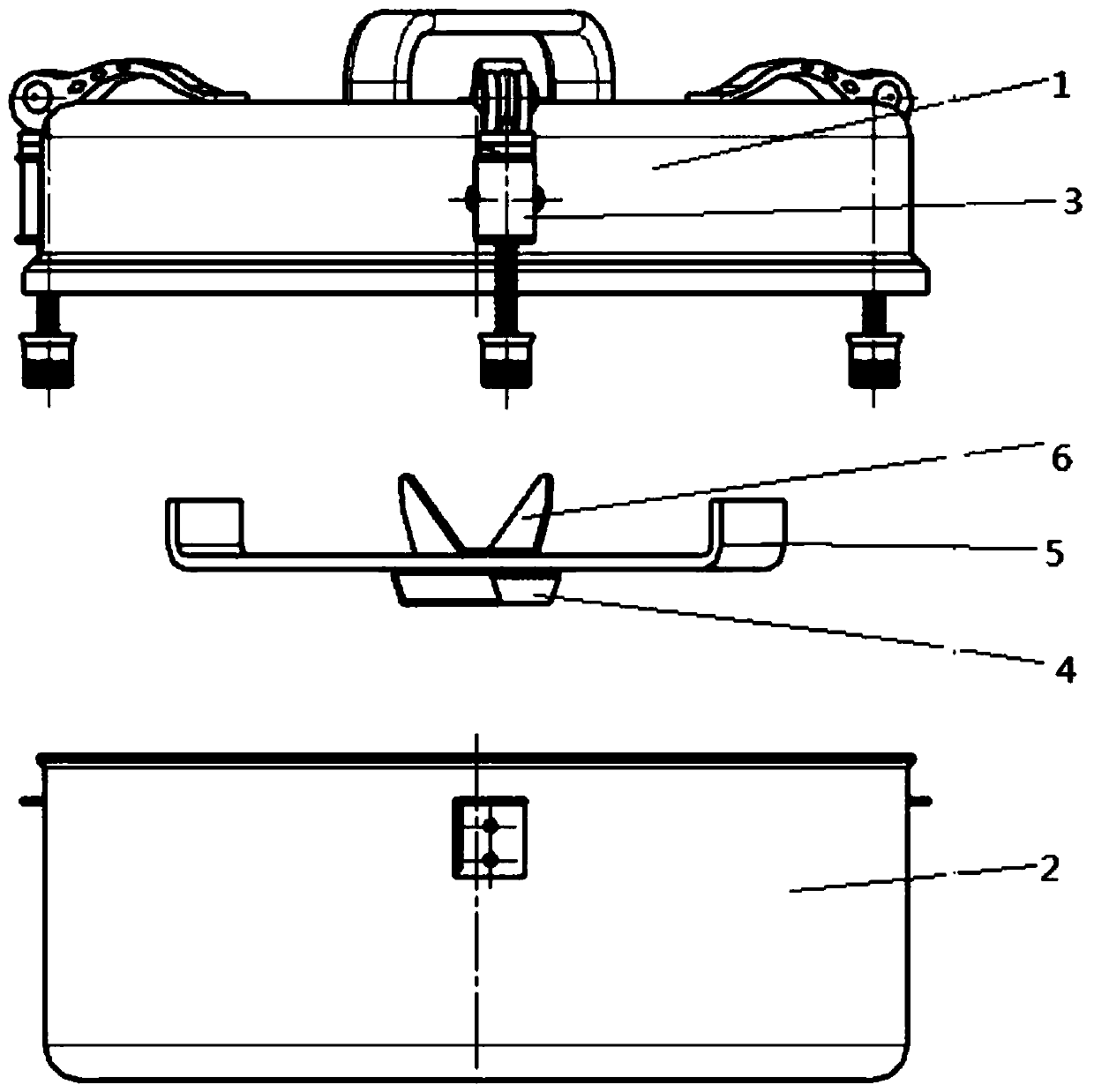

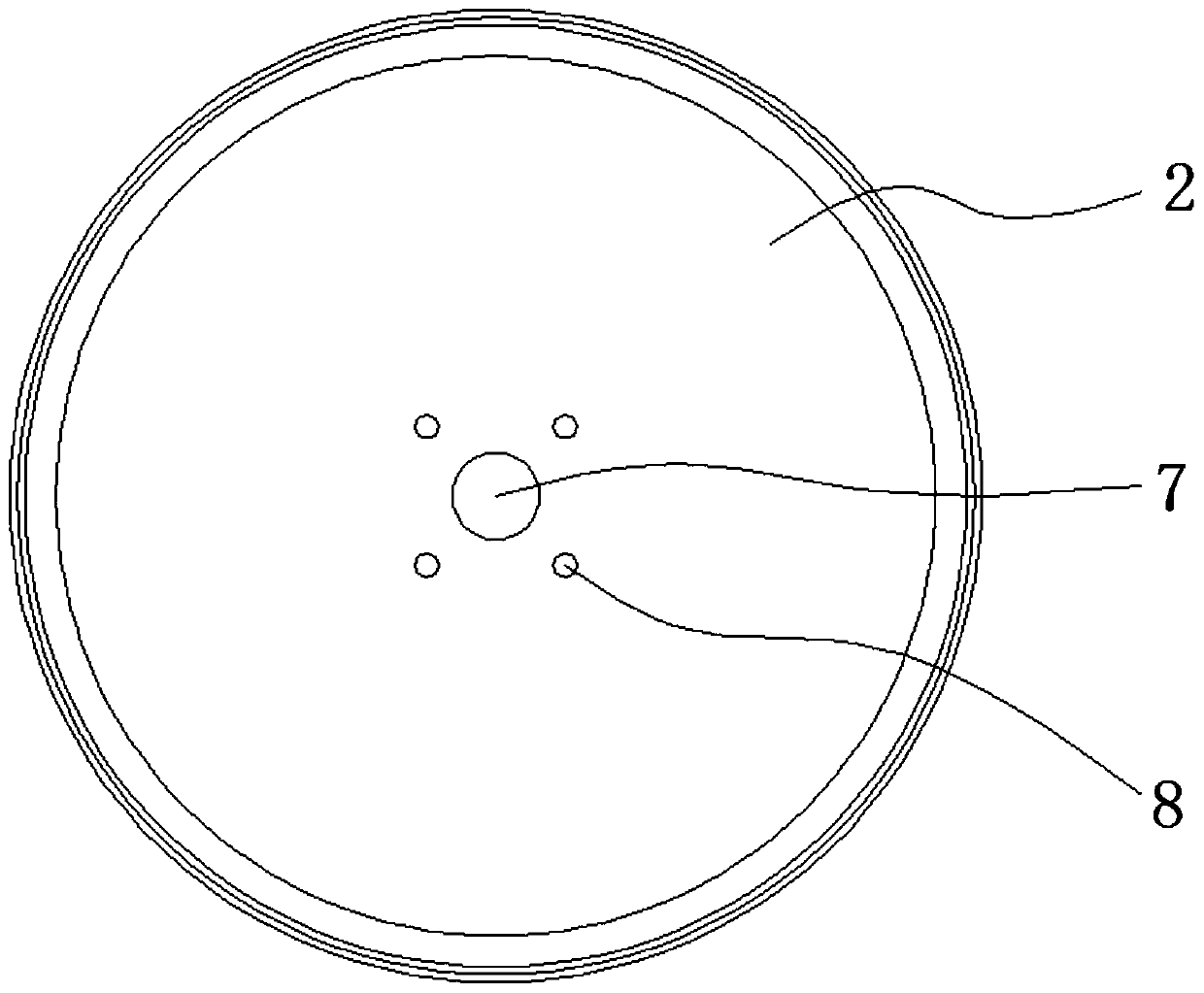

[0029] Please refer to figure 1 , figure 2 , image 3 , Figure 4 ,in, figure 1 A schematic structural view of a preferred embodiment of the main box of the crushing mill provided by the present invention; figure 2 for figure 1 The disassembled view of the main box of the pulverizer shown; image 3 for figure 1 The top view of the structure of the lower box shown; Figure 4 for figure 1 The schematic diagram of the structure of the lock shown. The main box of the pulverizer includes:

[0030] An upper box 1 and a lower box 2, the bottom of the upper box 1 is arranged on the top of the lower box 2;

[0031] A lock 3, the lock 3 is arranged on the outer surface of the upper box 1;

[0032] A blade 4, the blade 4 is arranged inside the lower box 2;

[0033] A knife brush 5, the knife brush 5 is arranged on the top of the blade 4.

[0034] In this embodiment, the crushing and grinding machine also includes: a motor assembly, the motor assembly includes a motor and a...

no. 2 example

[0051] Please refer to Figure 5 with Image 6 , based on the main box of the pulverizer provided in the first embodiment of the present application, the second embodiment of the present application proposes another main box of the pulverizer. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0052] Specifically, the difference between the main box of the pulverizing grinder provided in the second embodiment of the present application is that the main box of the pulverizing grinder:

[0053] The bottom of the upper box 1 is provided with a sealing structure 9, the sealing structure 9 includes a collar 91, the inner surface of the collar 91 is provided with an elastic sleeve 92, and the inner surface of the elastic sleeve 92 is provided with a non-slip sleeve 93, where the elastic sleeve 92 and the anti-skid sleeve 93 are all made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com