Cobalt-nitrogen co-doped carbon-based electrocatalyst material and preparation method thereof

An electrocatalyst and co-doping technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high catalyst cost, scarcity of precious metals, poor stability, etc., to improve catalytic performance, Improved catalytic activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This example provides a method for preparing a cobalt-nitrogen co-doped carbon-based electrocatalyst, which is prepared by the following steps:

[0050] (1) Preparation of Co-TPM complex: Soluble cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) (1mmol) and TPM (2mmol) are dissolved in the acetone solution of 10ml and 20ml respectively, in the process of stirring, the acetone solution containing cobalt salt is slowly added in the acetone solution containing TPM, and the mixture is stirred at room temperature for one hour hours; the precipitate was collected by centrifugation, washed with ethanol, and vacuum-dried at room temperature to obtain a yellow powder, which was the Co-TPM complex;

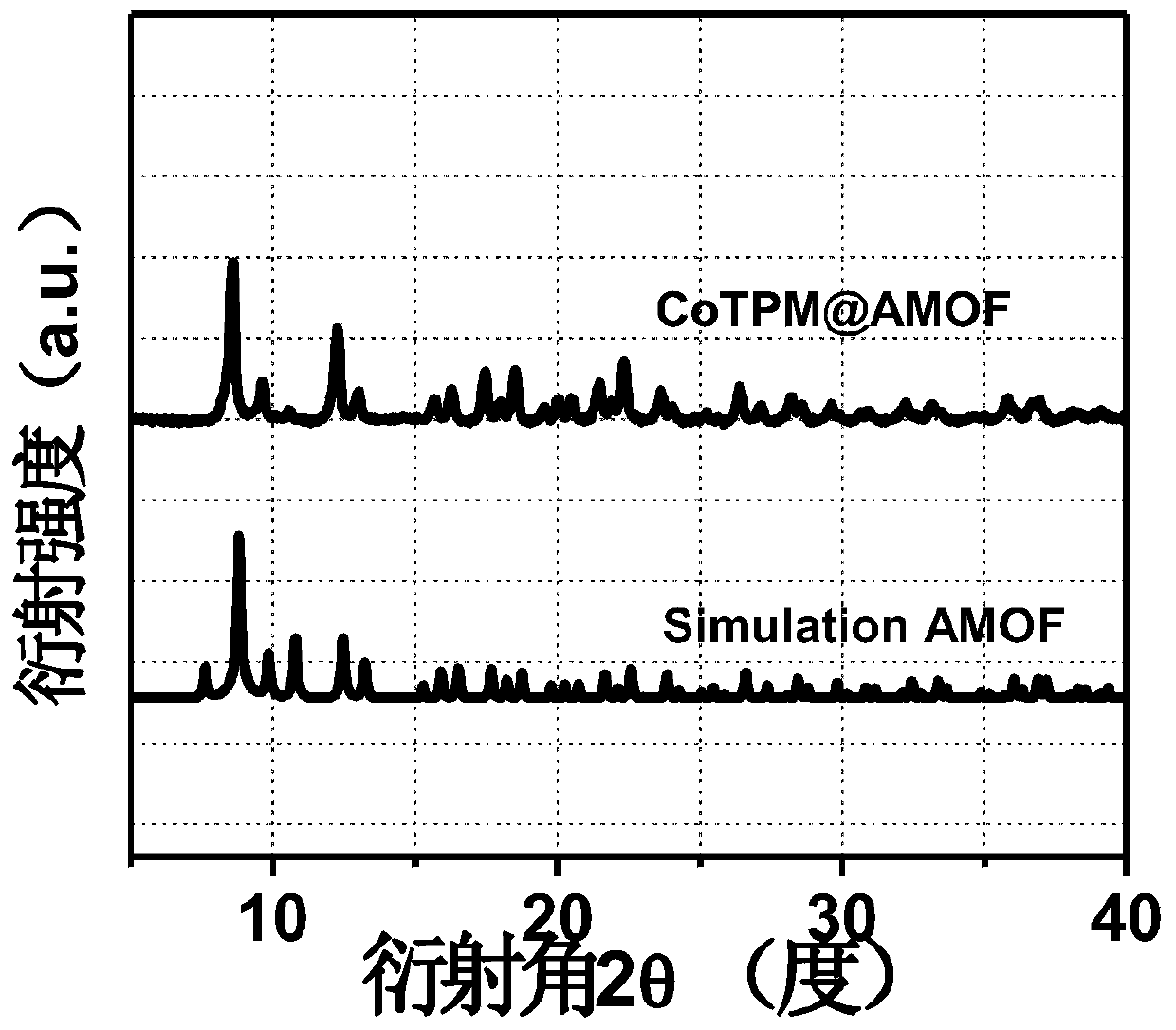

[0051] (2) Preparation of precursor Co@MOF: 10ml of Zn(NO 3 ) 2 (2.9mmol) of ammonia solution, 10ml of 1H-pyrazole-4-carboxylic acid (H 2 PzC) (3mmol) in methanol and 40ml of Co-TPM (0.4mmol) in DMF were added to a round bottom flask and refluxed for 6h. The precipitate was coll...

Embodiment 2

[0054] This example provides a method for preparing a cobalt-nitrogen co-doped carbon-based electrocatalyst, which is obtained through the following preparation steps:

[0055] (1) Preparation of Co-TPM complex: Soluble cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) (1mmol) and TPM (2mmol) are dissolved in the acetone solution of 10ml and 20ml respectively, in the process of stirring, the solution containing cobalt salt is slowly added in the solution of TPM, and the mixed solution is stirred at room temperature for one hour; Collect the precipitate, wash with ethanol, and dry at room temperature to obtain a yellow powder, which is the Co-TPM complex;

[0056] (2) Preparation of Co@MOF anionic MOF: 10ml of Zn(NO 3 ) 2 (2.8mmol) of ammonia solution, 10ml of 1H-pyrazole-4-carboxylic acid (H 2 PzC) (3mmol) in methanol and 40ml of Co-TPM (0.5mmol) in DMF were added to a round bottom flask and refluxed for 6h. The precipitate was collected by centrifugation, washed three ti...

Embodiment 3

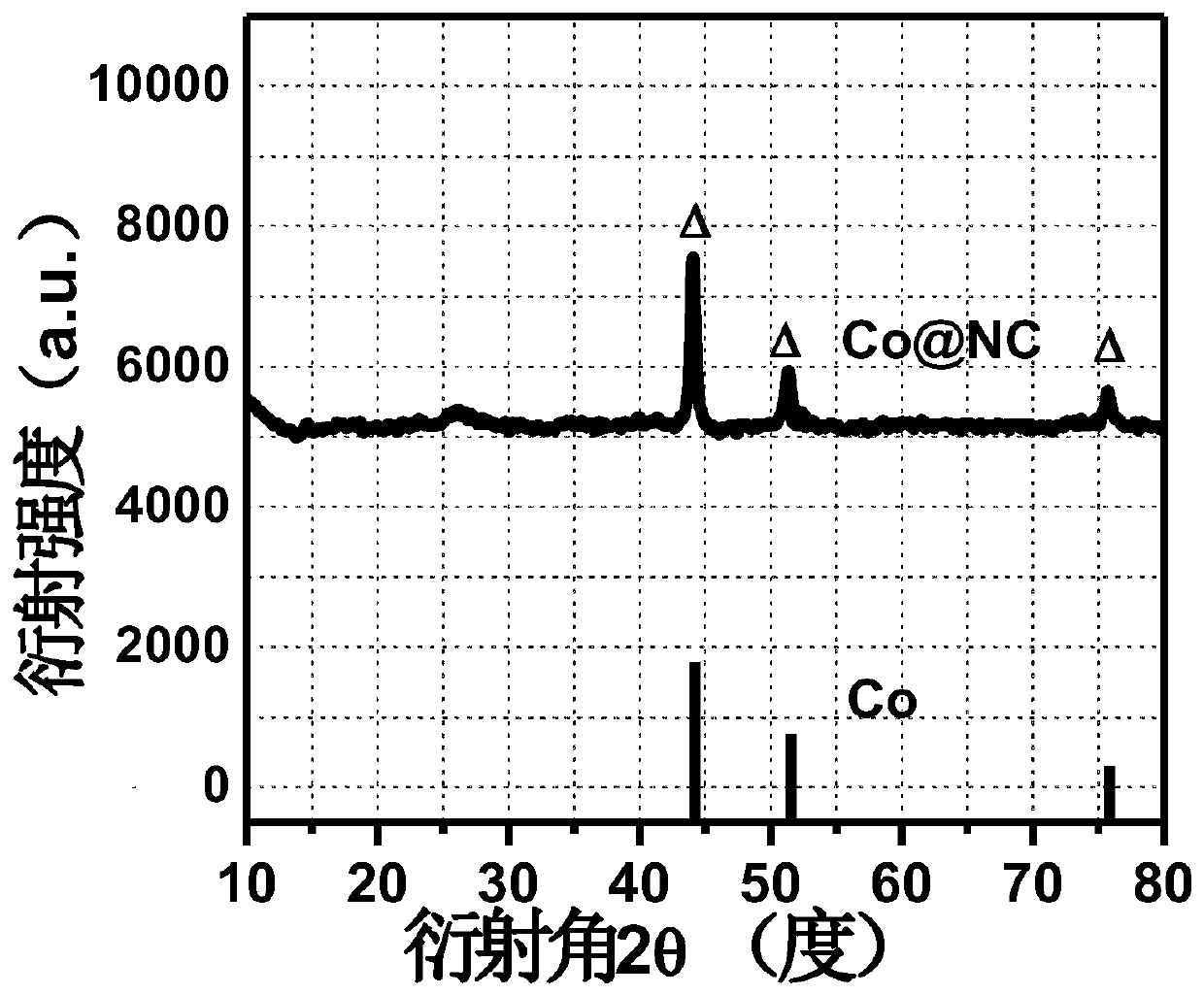

[0059] This example provides a method for preparing a nitrogen-doped carbon-based electrocatalyst encapsulating cobalt nanoparticles, which is obtained through the following preparation steps:

[0060] (1) Preparation of Co-TPM complex: Soluble cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) (1mmol) and TPM (2mmol) are dissolved in the acetone solution of 10ml and 20ml respectively, in the process of stirring, the solution containing cobalt salt is slowly added in the solution of TPM, and the mixed solution is stirred at room temperature for one hour; Collect the precipitate, wash with ethanol, and dry in vacuum to obtain a yellow powder, which is the Co-TPM complex;

[0061] (2) Preparation of Co@MOF anionic MOF: 10ml of Zn(NO 3 ) 2 (3.1mmol) of ammonia solution, 10ml of 1H-pyrazole-4-carboxylic acid (H 2 PzC) (3mmol) in methanol and 40ml of Co-TPM (0.2mmol) in DMF were added to a round bottom flask and refluxed for 6h. The precipitate was collected by centrifugation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com