Methylene blue antioxidant repair polymer nanofiber membrane and preparation method thereof

A nanofiber membrane, methylene blue technology, applied in medical science, absorbent pads, bandages, etc., can solve the problems that methylene blue is not easily absorbed through the skin, does not have the ability to release methylene blue slowly, and has low antioxidant effect, and achieves good skin feel and The effect of airtightness, promotion of transdermal absorption, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

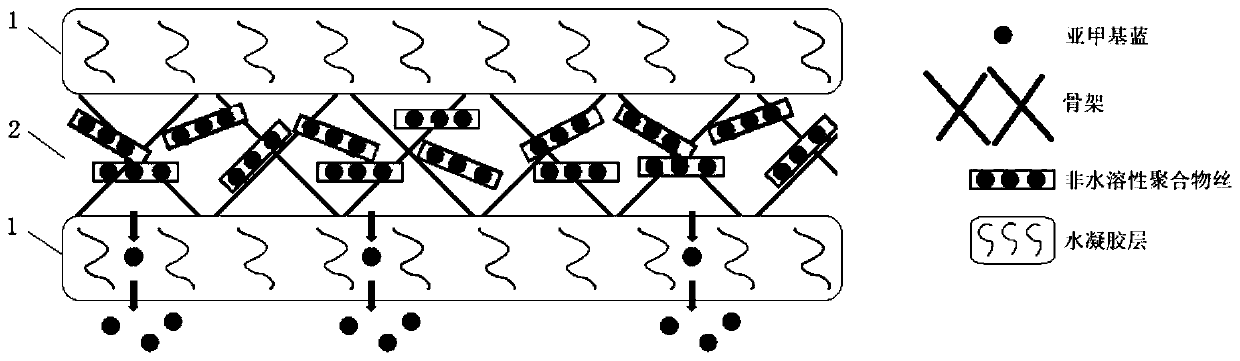

[0038] This embodiment provides a methylene blue anti-oxidation repairing polymer nanofiber membrane, which at least includes a three-layer structure of a hydrogel layer-nanofiber silk layer-hydrogel layer. Such as figure 1 As shown, the three-layer structure of a group of hydrogel layer-nanofiber silk layer-hydrogel layer is that the nanofiber silk layer 2 is sandwiched between two hydrogel layers 1 . The methylene blue anti-oxidation repairing polymer nanofiber membrane can also be composed of a three-layer structure of more than two sets of hydrogel layers-nanofiber silk layers-hydrogel layers.

[0039] The hydrogel layer includes chitosan and its derivatives, gel-forming natural macromolecular substances and salt ion substances, and is prepared by self-assembly and complex coagulation of chitosan and its derivatives and gel-forming natural macromolecular substances. The mass fraction of chitosan and its derivatives is 0.1%-50%, the mass fraction of gel-forming natural pol...

Embodiment 2

[0053] This embodiment provides a method for preparing the methylene blue anti-oxidation repairing polymer nanofiber membrane of embodiment 1, comprising the following steps:

[0054] S1. Configuration of electrospinning solution: dissolve a water-insoluble polymer with a mass of 0.01-50 g in an organic solvent to prepare a water-insoluble polymer solution with a mass fraction of 0.1%-50%, and add a mass of 0.01-50g of methylene blue, so that the mass fraction of methylene blue is 0.0001%-10%, to prepare electrospinning solution A;

[0055] S2. Preparation of nanofiber silk layer: electrospinning the electrospinning liquid A with ultra-high voltage and single nozzle, using the plant ultrafine fiber membrane as the receiver, that is, using the plant ultrafine fiber membrane as the skeleton to control the electrospinning The humidity of the environment is 10%-60%, the spinning voltage is 5kV-60kV, the speed of the syringe pump is 1ml / h-7.5ml / h, the distance between the needle ti...

example 1

[0062] The method for preparing the methylene blue anti-oxidation repairing polymer nanofiber membrane is as follows:

[0063] 1. Preparation of electrospinning solution: Dissolve polylactic acid in hexafluoroisopropanol at room temperature, and then add 0.5 g of methylene blue, so that the mass fraction of methylene blue is 0.5%, and the mass fraction of water-insoluble polymer is 15%. The electrospinning solution A.

[0064] 2. Preparation of the hydrogel layer solution: put sodium alginate into deionized water, heat to above 80°C and stir for 1 hour to obtain an aqueous solution of sodium alginate with a mass fraction of 2%; Chitosan with a relative molecular weight greater than 500KDa is dissolved in 1% acetic acid aqueous solution with a concentration of 1% under heating and stirring at 60°C to obtain a 2% chitosan acetic acid aqueous solution; dissolve calcium chloride in deionized water and stir at room temperature After 0.5 hour, a calcium chloride solution with a mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com