Composite coating for fuel cell polar plate and preparation method thereof

A fuel cell plate and composite coating technology, which is applied to fuel cell components, fuel cells, circuits, etc., can solve problems such as battery performance attenuation, improve durability and service life, enhance service performance, and ensure stability output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

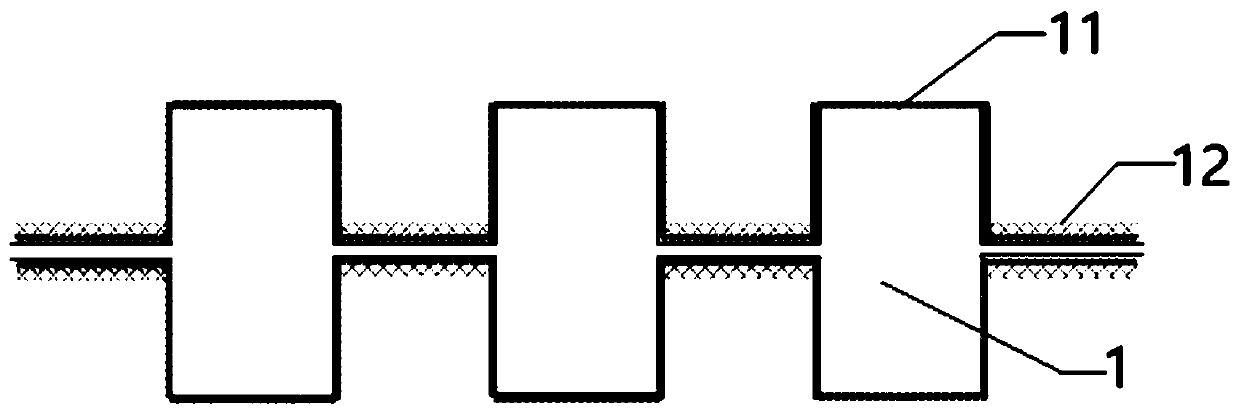

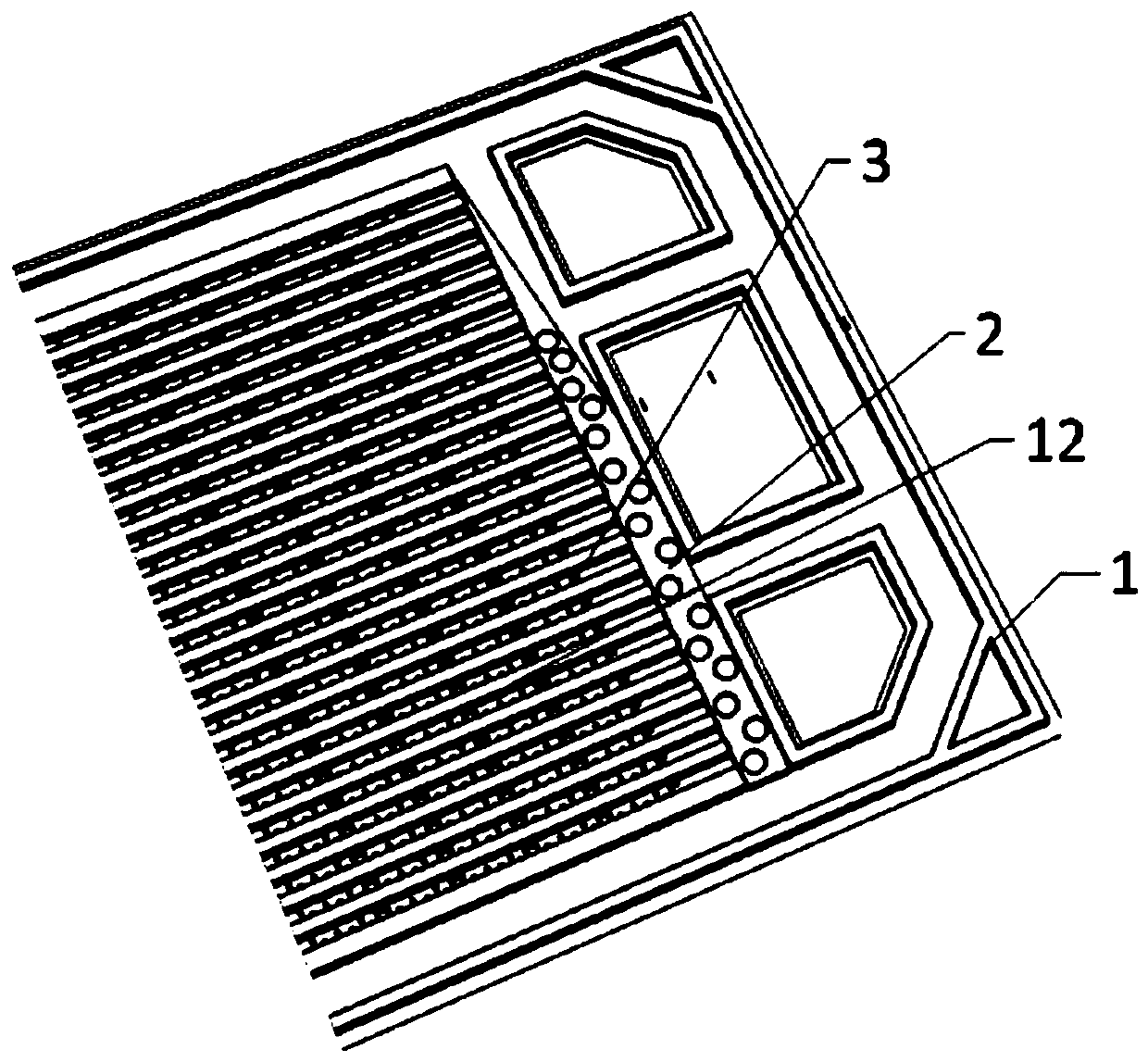

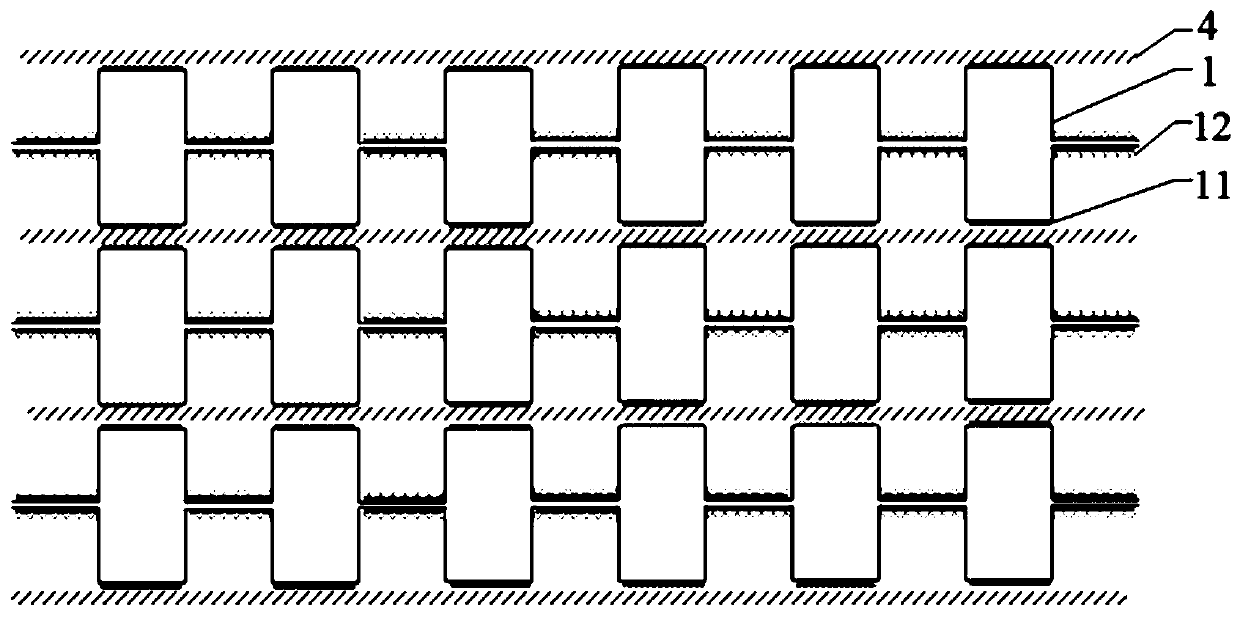

[0026] Select a mechanically formed metal plate with uniform thickness, and perform ultrasonic cleaning in ethanol and water to remove surface grease and surface debris; fix the metal plate of the fuel cell on the hanger, and transport it to the working place through the transmission guide rail. position; close the reaction chamber and evacuate its interior, when the vacuum is evacuated to 1Pa, turn on the heater for heating; when the temperature in the reaction chamber reaches the specified temperature, keep it warm for a period of time, and then pass through the gas path and air holes into the chamber Inject the reaction gas, and control the vacuum degree required by the process through the exhaust system, adjust the bias voltage and gas flow; use the reactive sputtering method to uniformly deposit a layer of Cr-C carbide (chromium carbide) conductive corrosion-resistant coating on the surface of the metal plate layer; then brush a layer of aqueous solution of nano-fluorine s...

Embodiment 2

[0029] Select a mechanically formed metal plate with uniform thickness, and perform ultrasonic cleaning in ethanol and water to remove surface grease and surface debris; use laser cladding to deposit a layer of W-C carbide (tungsten carbide) on the surface of the metal plate Conductive anti-corrosion coating; then send the metal pole plate with conductive anti-corrosion coating into the vacuum chamber, magnetron sputtering PTFE target, use the corresponding partition device to make the sputtered PTFE coating adhere to the metal pole In the channel bottom of the reaction area of the plate and the distribution area of the metal pole plate; the fuel cell pole plate with the composite coating of the present invention can be obtained.

[0030] The contact angle of the obtained hydrophobic material film layer is 123°, which is much higher than that of the conductive corrosion-resistant coating, and the surface properties of the hydrophobic material film layer have not occurred si...

Embodiment 3

[0032] A mechanically formed metal plate with a uniform thickness is selected and ultrasonically cleaned in ethanol and water to remove surface grease and surface debris; a layer of Ti-C carbide (titanium carbide) is deposited on the surface of the metal plate by reactive sputtering. ) Conductive anti-corrosion coating; Then utilize the gas spray gun, nano-SiO2 and nano-F-SiO 2 The ethanol dispersion liquid is evenly sprayed onto the distribution area of the metal pole plate and the flow channel bottom of the reaction area; the fuel cell pole plate with the composite coating of the present invention can be obtained.

[0033] The contact angle of the obtained hydrophobic material film layer is 128°, which is much higher than that of the conductive corrosion-resistant coating, and the surface performance of the hydrophobic material film layer does not occur after being placed in an acidic solution with pH=3 for more than 200 hours and in the air for more than 1000 hours Signif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com