A kind of au-au dimer array structure and its preparation method and application

A dimer, au-au technology, applied in measurement devices, instruments, material analysis by optical means, etc., can solve the problems of complex methods, difficult to control repeatability, poor repeatability of test results, etc., and achieve a simple process. , Raman signal stabilization, enhance the effect of plasmon resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This example discloses the implementation of the construction of the first gold particles, as follows:

[0059] Cut out two silicon wafers, the thickness is 0.2mm, the size is 2cm×2cm, and they are marked as No. Sulfuric acid, 1.1g / m hydrogen peroxide water, and deionized water were used for ultrasonic cleaning. The ultrasonic frequency was 20KHz and the ultrasonic power was 500W. After evaporation, place the silicon wafer in an ultraviolet ozone cleaner for 30 minutes of irradiation to obtain a silicon wafer with a hydrophilic surface;

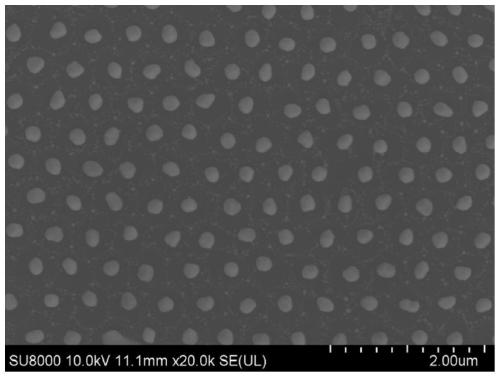

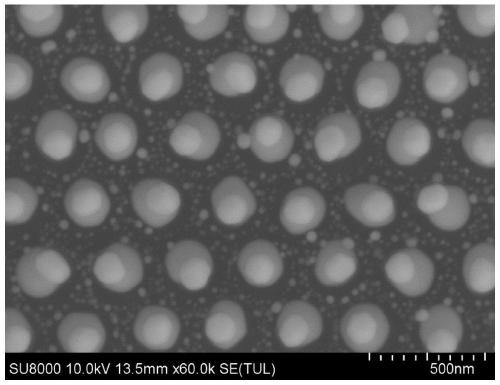

[0060] Take 10 μL of polystyrene microsphere suspension with a content of 2.5wt% and a diameter of 300nm and 500nm respectively, and mix it with an equal volume of absolute ethanol, and then carry out ultrasonic vibration for 30min, so that uniformly dispersed polystyrene microspheres can be prepared. Microsphere ethanol dilution solution, ultrasonic frequency 40KHz, ultrasonic power 300W, and then adopt the gas-liquid interface self-...

Embodiment 2

[0066] This example discloses an implementation of an Au-Au dimer array structure, specifically as follows:

[0067] Cut out 3 pieces of silicon wafers, the thickness is 0.2mm, the size is 2cm×2cm, marked as No. 1, 2, and 3 silicon wafers, and then put these silicon wafers into deionized water, absolute ethanol, acetone, ml concentrated sulfuric acid, 1.1g / ml hydrogen peroxide, and deionized water for ultrasonic cleaning. The ultrasonic frequency is 20KHz and the ultrasonic power is 1000W. Each liquid is ultrasonically cleaned for 40 minutes, and then placed in an oven for drying at 90°C until the water on the silicon wafer is completely evaporated. Finally, place the silicon wafer in an ultraviolet ozone cleaning machine for 30 minutes of irradiation to obtain a silicon wafer with a hydrophilic surface;

[0068] Take 20 μL of polystyrene microsphere suspension with a content of 2.5wt% and a diameter of 300 nm, mix it with an equal volume of absolute ethanol, and then conduct ...

Embodiment 3

[0080] This example discloses an implementation of an Au-Au dimer array structure, specifically as follows:

[0081]Cut out 3 pieces of silicon wafers with a thickness of 0.2mm and a size of 2cm×2cm. Put the silicon wafers into deionized water, absolute ethanol, acetone, 1.84g / ml concentrated sulfuric acid, 1.1g / ml hydrogen peroxide, deionized Ultrasonic cleaning in ionized water, ultrasonic frequency 20KHz, ultrasonic power 500W, each liquid was ultrasonically cleaned for 40 minutes, and then dried in an oven at 110°C. After the water on the silicon wafer was completely evaporated, the silicon wafer was placed in an ultraviolet ozone cleaning machine Medium irradiation for 30 minutes to obtain a silicon wafer with a hydrophilic surface;

[0082] Take 10 μL of polystyrene microsphere suspension with a content of 2.5wt% and a diameter of 500 nm, mix it with an equal volume of absolute ethanol, and then perform ultrasonic oscillation for 15 minutes to obtain a uniformly disperse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com