Method for automatically and quickly digesting food sample

A food and sample technology, which is applied in the field of physical and chemical inspection of food hygiene, can solve the problems of many types of acid used, small amount of digested samples, and small environmental pollution, so as to improve economic and ecological benefits, use less types and amounts of reagents, and reduce The effect of the amount of nitric acid used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for automatically and quickly digesting food samples, the specific steps are:

[0051] Sample weighing, weigh 0.5-2g of solid sample (accurate to 0.001g, increase the sampling amount to 5g for samples with more water content) or pipette 1.00-5.00mL of liquid sample into a polytetrafluoroethylene digestion tube, containing The ethanol sample is first heated on an electric heating plate at low temperature to remove ethanol;

[0052] 1. Place the PTFE digestion tube with the weighed sample in the automatic graphite digestion instrument and run the digestion program; when the digestion tube is placed in the automatic graphite digestion instrument, the bottom 1 / 4 to 1 / 2 of the digestion tube body is located Heating in graphite pores; 2.0-6.0mL of high-purity nitric acid added;

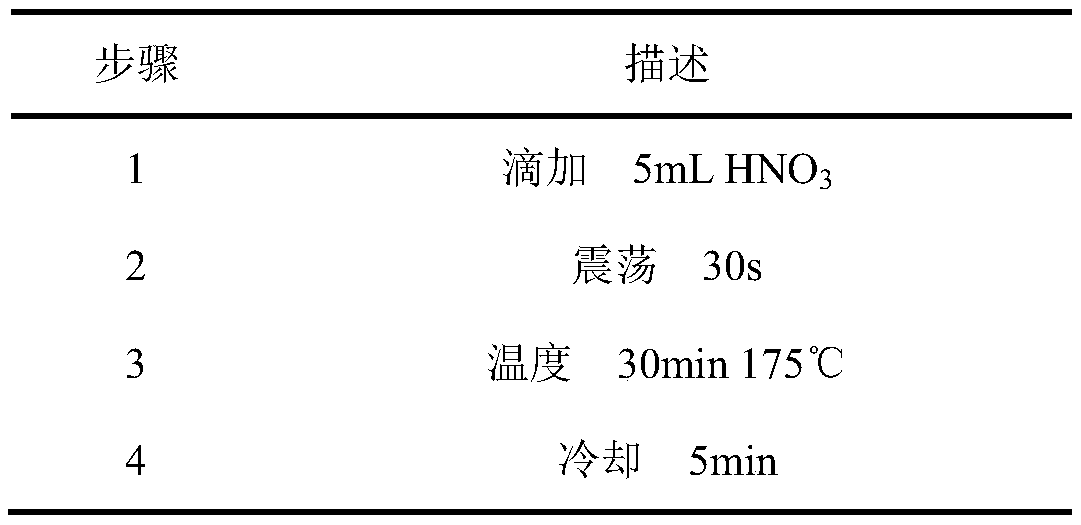

[0053] 2. After the instrument automatically finishes adding nitric acid, cover the lid of the digestion tube, and then heat up the sample for digestion. The digestion procedure is shown in...

Embodiment 2

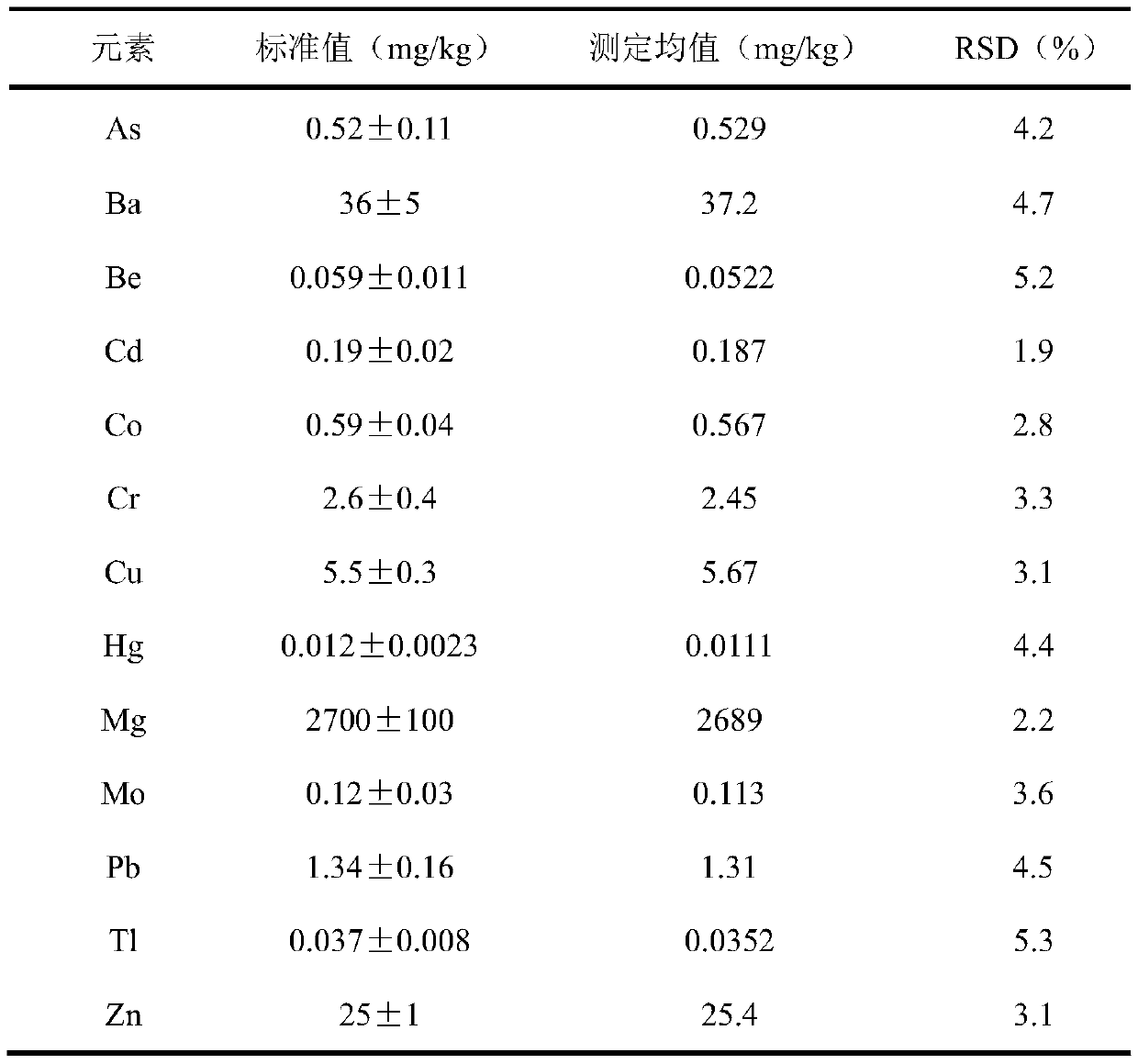

[0059] Embodiment 2: analyze the accuracy test of GBW10049 (GSB-27) scallion component analysis reference material

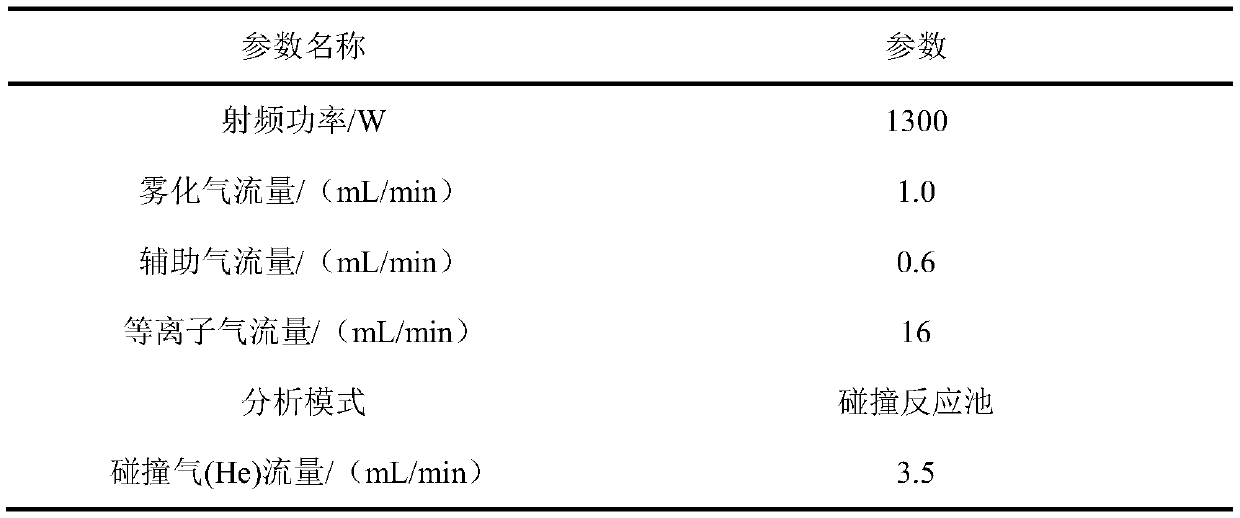

[0060] Adopt the method of embodiment 1 to analyze GBW10049 (GSB-27) scallion component analysis standard substance, wherein, sample digestion: accurately weigh GBW10049 (GSB-27) scallion powder 1g (accurate to 0.001g), place in 50mL polytetrafluoroethylene Add 5.0 mL of high-purity nitric acid into the digestion tube, and perform digestion according to the above digestion method. After digestion, dilute to 50 mL with pure water. The clear liquid was taken and supplied to an inductively coupled plasma mass spectrometer for measurement, and the measurement results are shown in Table 3.

[0061] Table 3 Determination results of some elements in GBW10049 (GSB-27) scallions (n=3)

[0062]

Embodiment 3

[0063] Embodiment 3: the impact of different parameter conditions on the accuracy of the method

[0064] The method of Example 1 was used to analyze GBW10049 (GSB-27) scallion component analysis standard substance, the difference being that the parameter conditions of the digestion program were changed. See Table 4 for specific parameter condition settings, and Table 5 for the measurement results.

[0065] Table 4 Graphite digestion program

[0066]

[0067] By changing the digestion parameter conditions, it can be seen that in the process of heating and digesting samples with concentrated nitric acid, when the digestion solution is uniform and clear, most of the components in the sample are decomposed or transferred to the acid solution, but a small number of elements such as chromium need to be digested. It can only be transferred out under certain digestion conditions (temperature greater than 160°C, time greater than 20min, nitric acid usage greater than 4mL). After s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com