Bearing pedestal noise processing system for NVH test of pure electric vehicle electric drive system

A pure electric vehicle and electric drive system technology, which is applied in vehicle testing, machine/structural component testing, sounding equipment, etc., can solve problems such as NVH acquisition data distortion, optimize sound field space, reduce structural volume, and reduce sound waves The effect of reflective surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

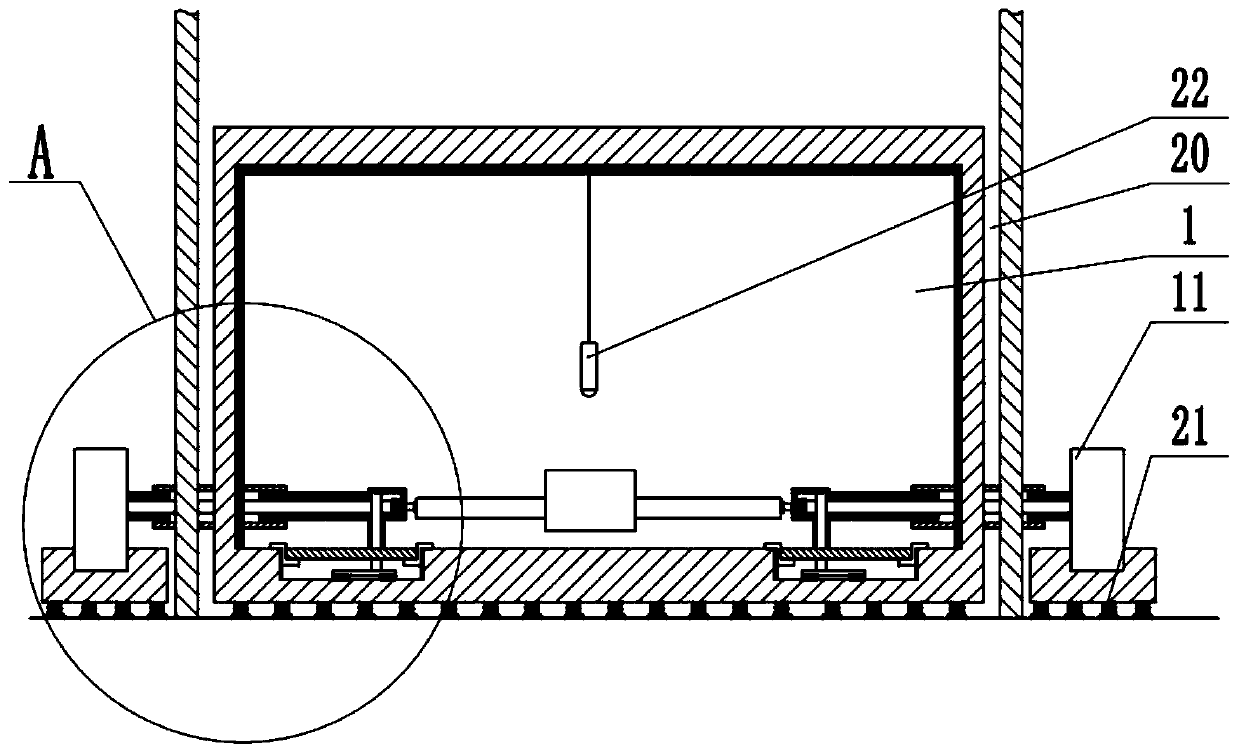

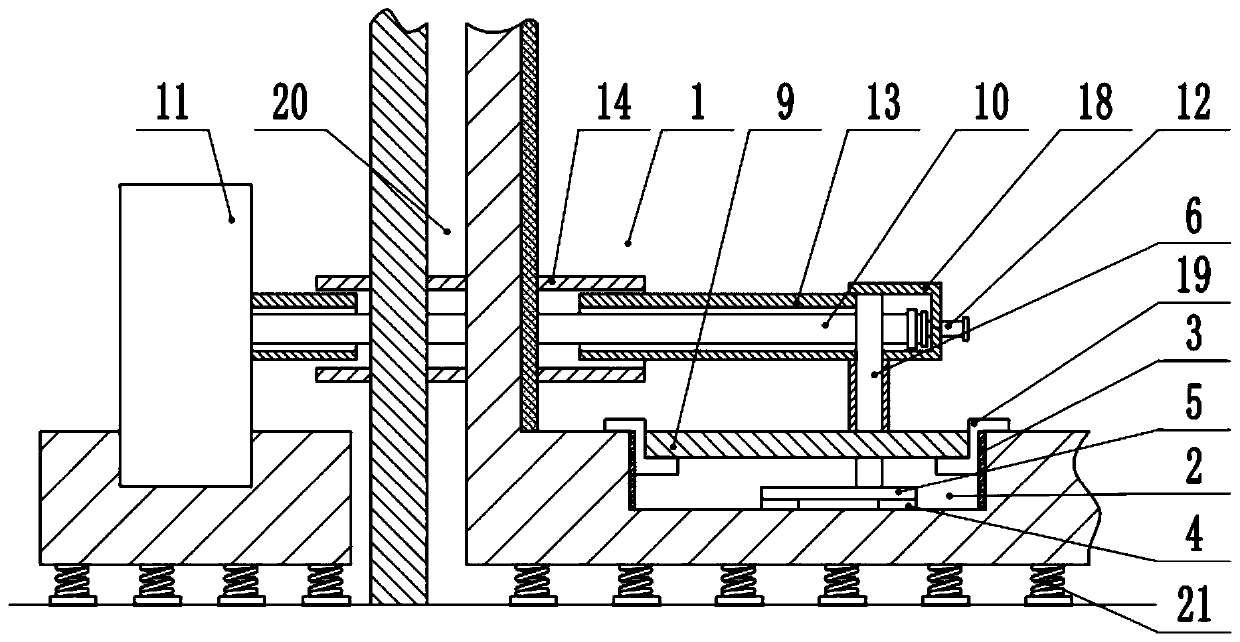

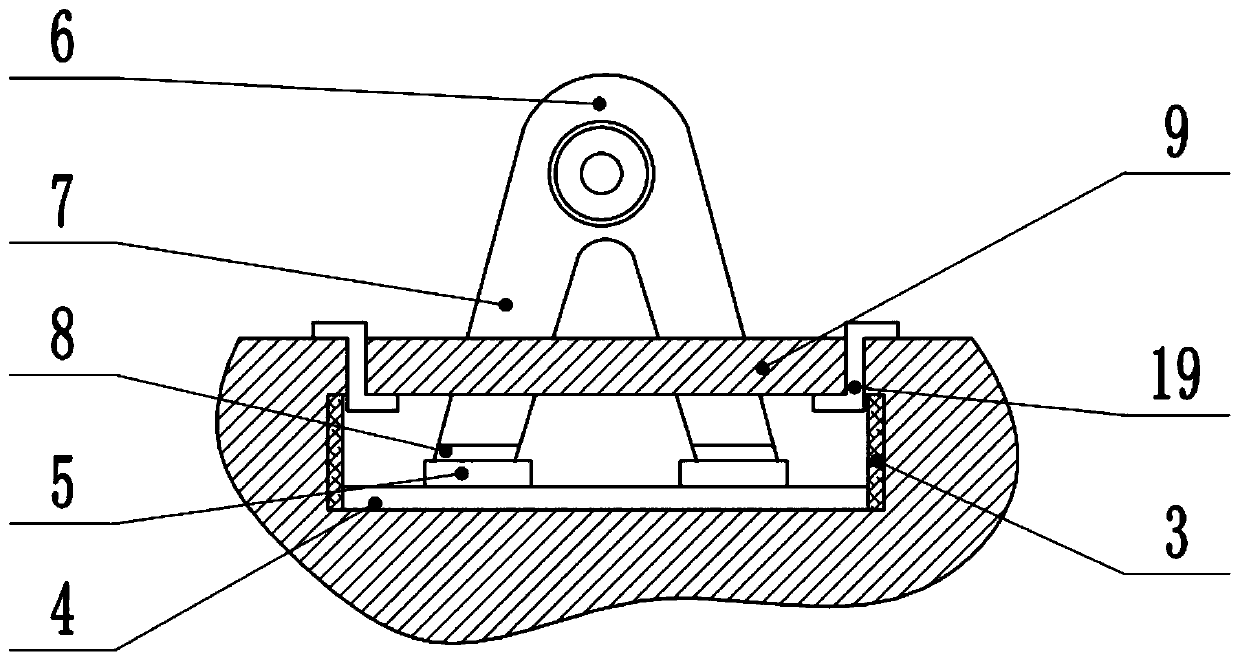

[0033] Basic as attached figure 1 , attached figure 2 and attached image 3 Shown: The noise treatment system for bearing housings used in the NVH test of the pure electric vehicle electric drive system, including a semi-anechoic chamber 1, the wall of the semi-anechoic chamber 1 includes two layers of inner and outer layers, and an air layer 20 is separated between the inner and outer layers of walls . The indoor center of the semi-anechoic chamber 1 is fixed with a microphone 22 suspended in the air for measuring and controlling noise. A damping spring 21 is fixedly connected to the bottom of the semi-anechoic chamber 1, and the end of the damping spring 21 away from the semi-anechoic chamber is fixedly connected to the foundation. The inner wall surface of the semi-anechoic chamber 1 except the ground is fixedly connected with special sound-absorbing components. There is a basement 2 under the ground in the semi-anechoic chamber 1, and the top of the basement 2 communi...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that, as Figure 4 As shown, the fixed acoustic component 14 is made of the same material as the movable acoustic component 13, and is divided into an inner layer, a middle layer and an outer layer from inside to outside. The outermost and innermost layers are perforated steel plates 15, the middle layer is a sound-insulating steel plate 16 with a thickness of 2 mm, and sound-absorbing materials are filled between the sound-insulating steel plates 16 and the inner and outer sound-insulating steel plates 16, and the sound-absorbing materials are on the side close to the perforated steel plates 15. Also be provided with nonwoven fabric 17, the thickness of whole structure is controlled at 50~150mm.

[0039] The specific implementation process is as follows: when the sound wave passes through the surface of the fixed acoustic component 14 and the mobile acoustic component 13, the sound wave will pass through the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com