Swing arm moving roller detection device for irregular bulk material stack height detection

A technology of height detection and detection devices, which is applied in the direction of liquid level indicators for physical variable measurement, parts of strapping machinery, etc., can solve problems such as low efficiency, bale cannot be formed, waste, etc., and achieve the reduction of dependence on proficiency, The material is highly authentic and reliable, and the effect of enhancing the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

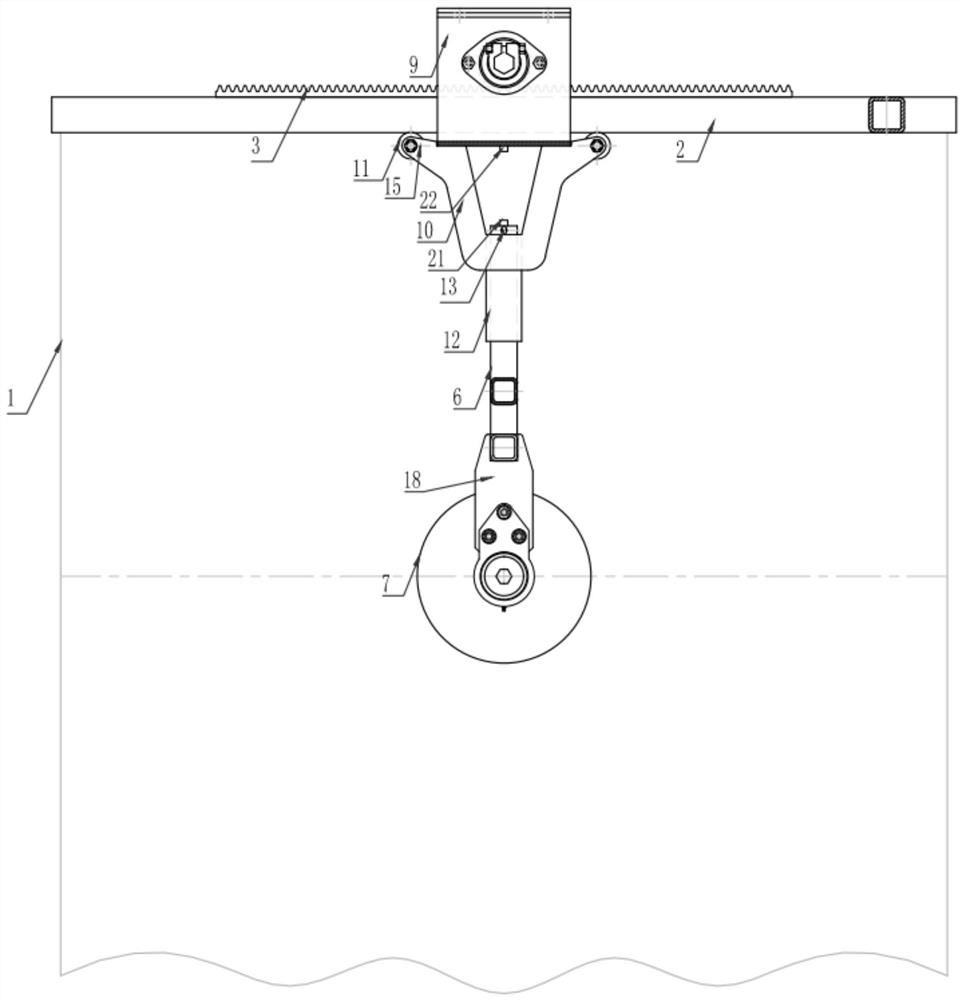

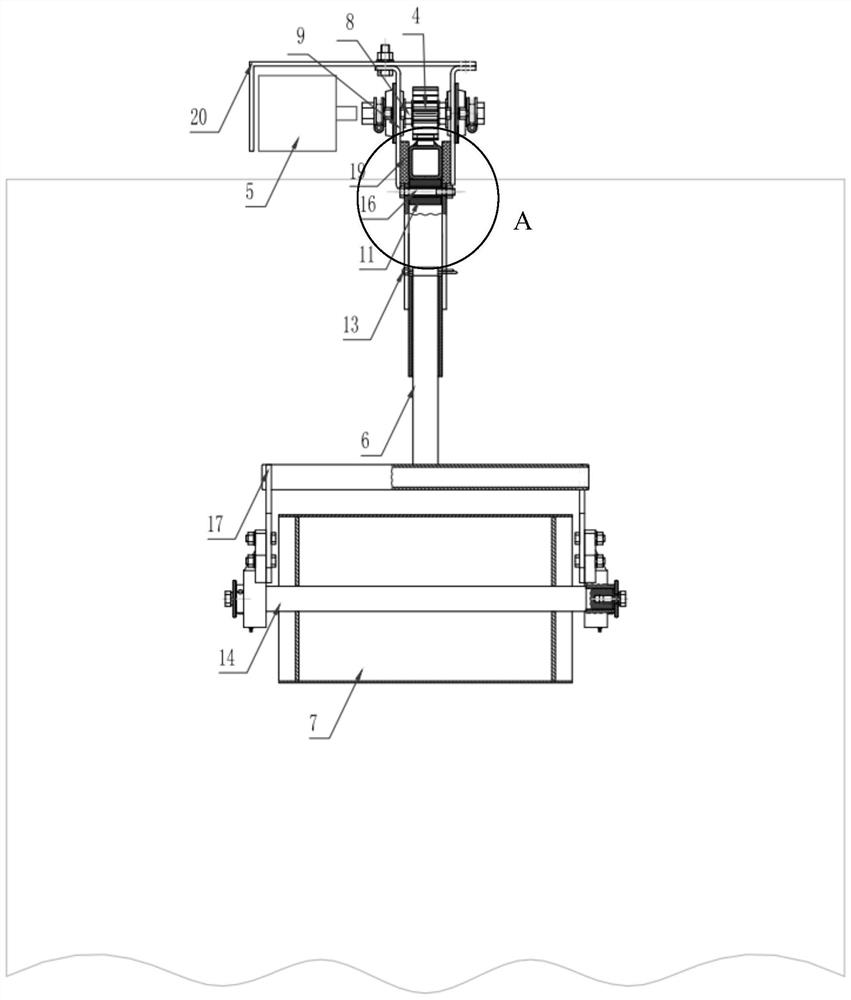

[0035] Such as Figure 1-Figure 5 As shown, a swing arm mobile roller type detection device for detecting the height of irregular bulk material piles includes a square tube support 2 arranged on the top of the silo 1, a rack 3 fixed on the square tube support 2, and The gear 4 meshed with the rack 3, the motor 5 driving the gear 4 to rotate, the vertically arranged mechanical arm 6 and the roller 7;

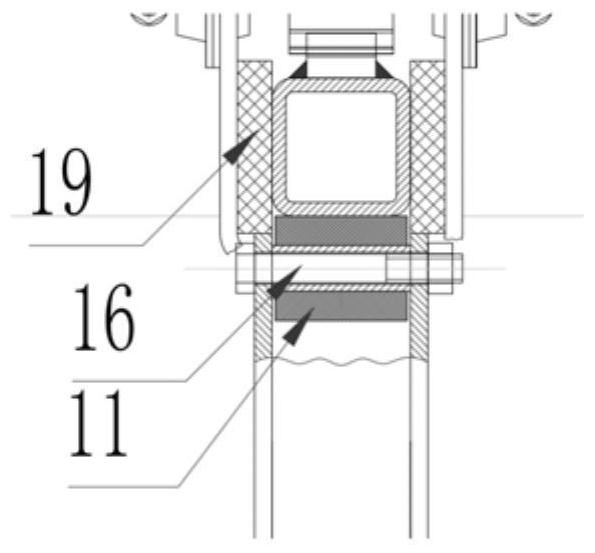

[0036] Described gear 4 is installed on the gear rack 9 by gear shaft 8, and described gear rack 9 is sleeved on the square pipe support 2, and is fixedly provided with two symmetrically arranged along the square pipe support 2 length directions at the bottom of gear rack 9. A support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com