Rare earth corrosion-resistant steel rich in alloyed rare earth elements and manufacturing method of rare earth corrosion-resistant steel

A technology of alloying elements and rare earth elements, which is applied to rare earth corrosion-resistant steel rich in alloying rare earth elements and its manufacturing field, can solve the problems of incapable of stable batch production, high smelting cost, and not belonging to conventional mass production processes, etc. , to solve the problem of excess light rare earth resources, improve atmospheric corrosion resistance, major economic benefits and environmental protection significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

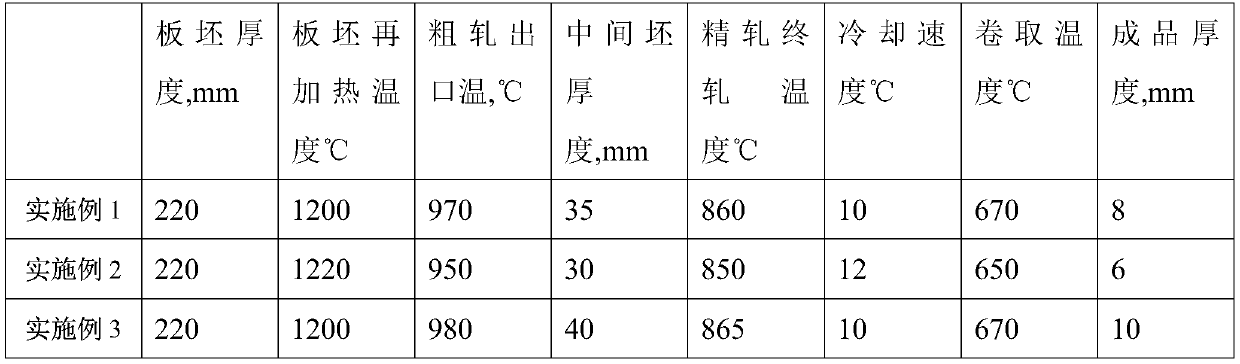

[0034] Embodiment: According to the composition requirements of the steel of the present invention, the manufacturing method of economical corrosion-resistant steel provided by the present invention, the smelting process includes converter blowing, LF refining, slab continuous casting, slab hot delivery, slab heating, control Rolling, controlled cooling, coiling and finishing. The steelmaking-continuous casting process includes hot metal desulfurization and slag removal pretreatment, top-bottom combined blowing converter blowing, tapping alloying, LF refining, and slab continuous casting. Desulfurization by spraying lime powder into the ladle, and then mechanically removing slag with a slag removal car, the temperature of the molten iron is ≥ 1300 ° C, and S ≤ 0.007%. After the converter is splashed with slag to protect the furnace, the shaking furnace is first loaded with scrap steel, and then mixed with molten iron. Converter blowing, removal of P and C, blowing end point 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com