Coal preparation method of coking coal material

A coking coal and coal material technology, applied in coking ovens, petroleum industry, etc., can solve problems such as the inability to optimize coal blending schemes in a targeted manner, and achieve the effects of expanding particle size difference, effective combination, and homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

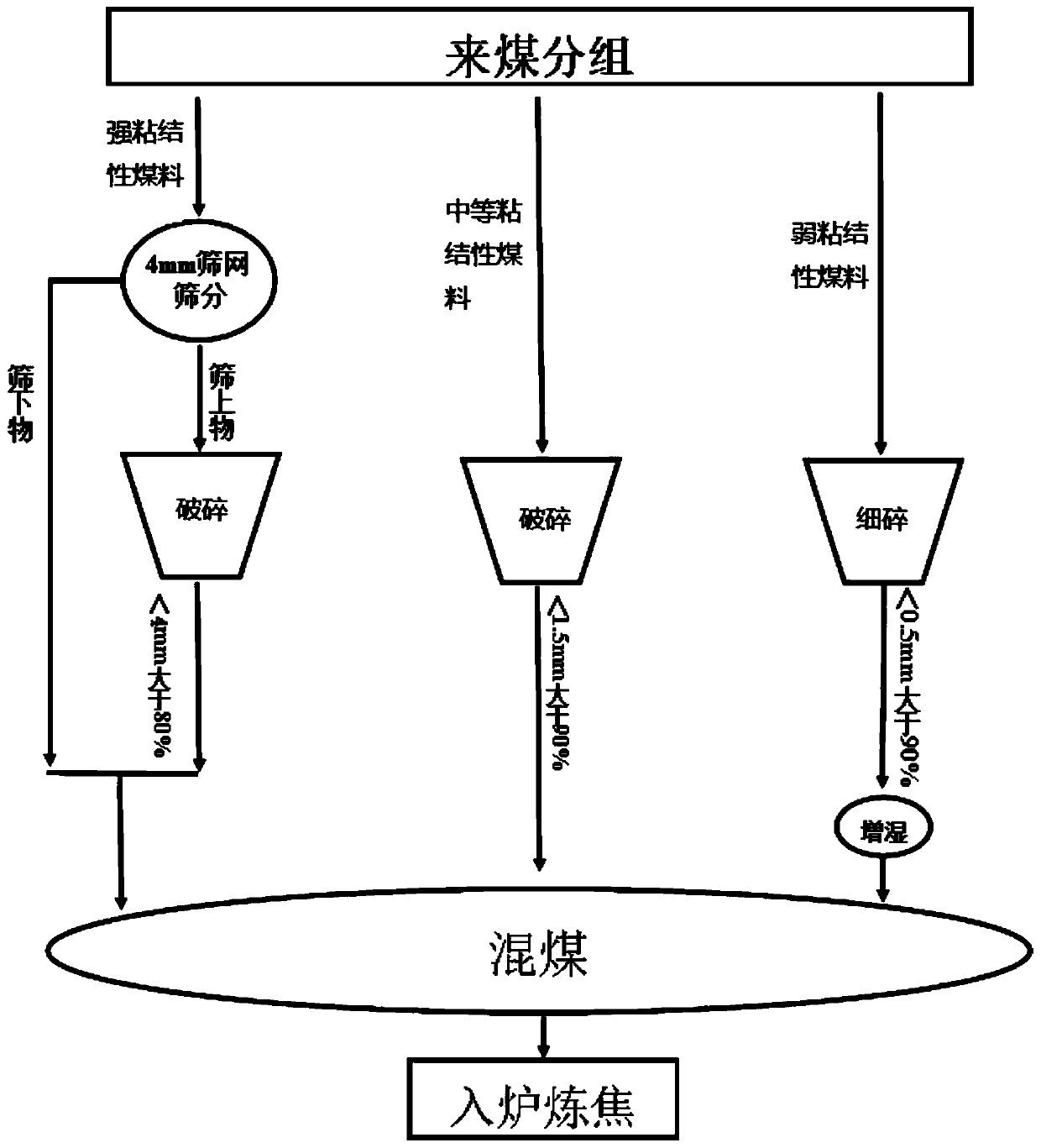

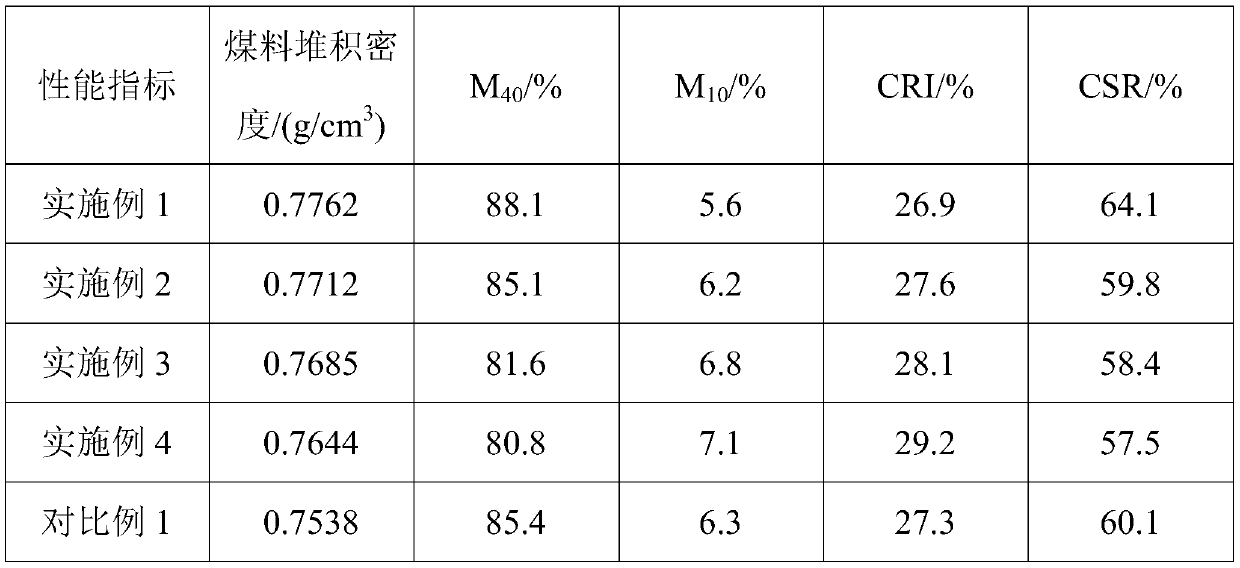

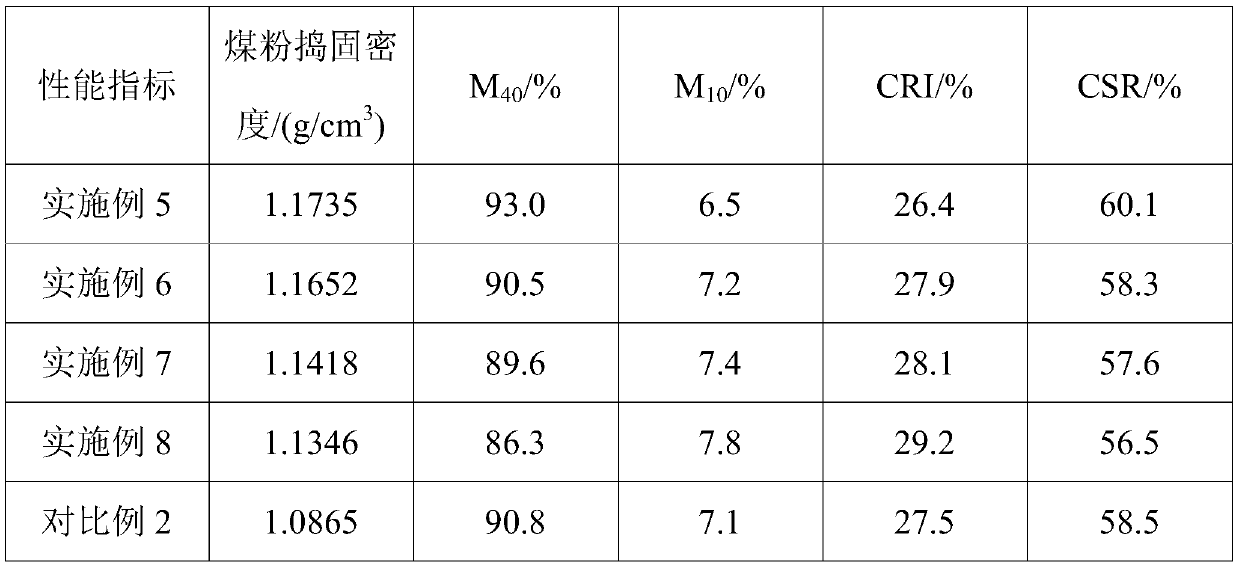

[0055] The present embodiment provides a kind of coal preparation method of coking coal material, and the process flow chart of described method is as follows figure 1 shown, including the following steps:

[0056] (1) After mixing coking coal, fat coal, and gas fat coal according to the proportion, first pass through a 4mm sieve for screening, and the oversize enters the crusher, and crushes until the particles with a particle size of less than 4mm account for 80wt%, and then mix with the under-sieve The mixture is evenly mixed, and the average particle size of the mixed particles is 2.80mm; the lean coal and gas coal are put into the crusher according to the ratio, and the particles with a particle size of less than 1.5mm account for 90wt%, and the average particle size of the crushed particles is 0.60mm; the lean coal and coke powder are put into the fine crusher according to the ratio, and the particles that are finely crushed to a particle size of less than 0.5mm account ...

Embodiment 2

[0059] The present embodiment provides a kind of coal preparation method of coking coal material, and described method comprises the following steps:

[0060] (1) After mixing coking coal and fat coal according to the proportion, first pass through a 4mm sieve for sieving, and the oversize enters the crusher, crushed until particles with a particle size less than 4mm account for 85wt%, and then mix with the undersize evenly, The average particle size of the mixed particles is 2.60mm; the lean coal and gas coal are put into the crusher according to the ratio, and the particles that are crushed to a particle size of less than 1.5mm account for 92wt%, and the average particle size of the crushed particles is 0.55mm; Lean and lean coal and coke powder enter the fine crusher according to the ratio, and the finely crushed particles with a particle size of less than 0.5mm account for 92wt%, and the average particle size of the finely crushed particles is 0.13mm. wet processing;

[0...

Embodiment 3

[0063] The present embodiment provides a kind of coal preparation method of coking coal material, and described method comprises the following steps:

[0064] (1) After mixing coking coal, fat coal, and 1 / 3 coking coal according to the ratio, first pass through a 4mm sieve for screening, and the oversize enters the crusher, and crushes until the particles with a particle size of less than 4mm account for 90wt%, and then mix with the sieve The material is mixed evenly, and the average particle size of the mixed particles is 2.40mm; the lean coal, gas coal, and 1 / 2 medium caking coal are put into the crusher according to the proportion, and the particles with a particle size of less than 1.5mm account for 95wt%. The average particle size of the crushed particles is 0.50mm; the coke powder enters the fine crusher, and the particles that are finely crushed to a particle size of less than 0.5mm account for 95% by weight, and the average particle size of the finely crushed particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com