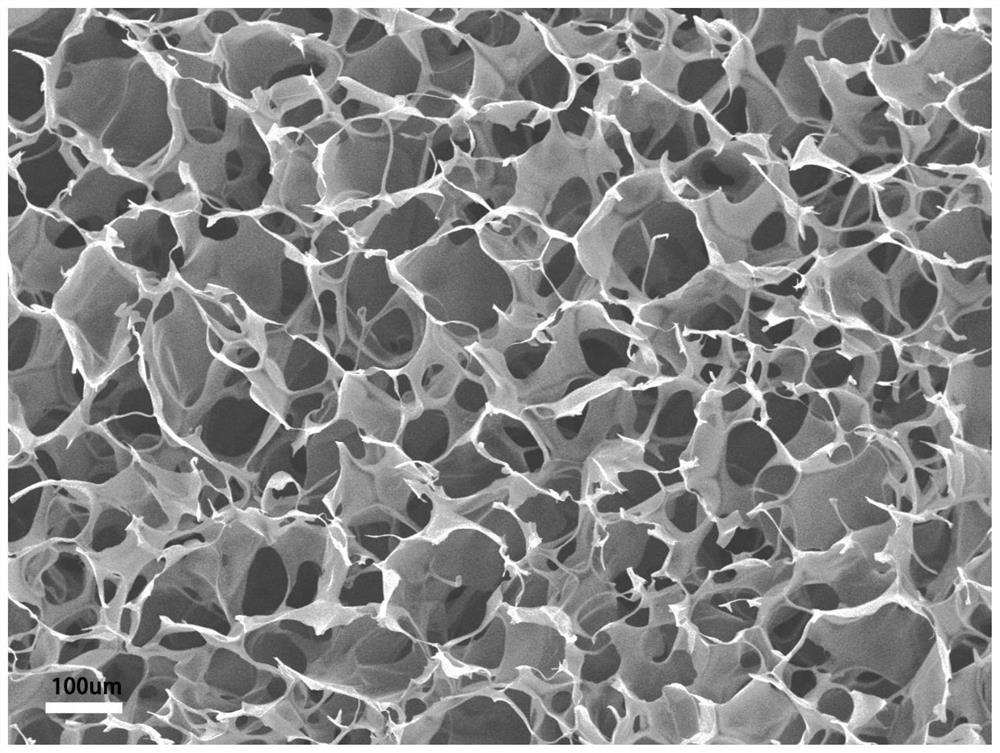

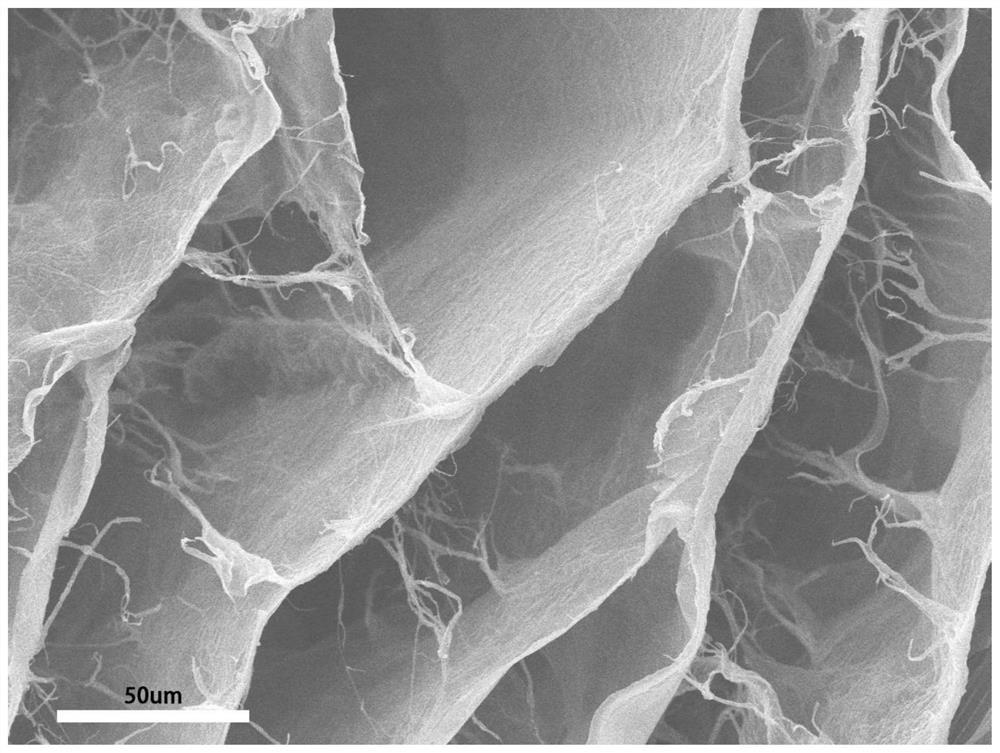

A kind of nanofiber chitosan porous material and preparation method thereof

A technology of nanofibers and porous materials, applied in the field of porous materials, can solve the problems of difficulty in obtaining porous materials with comprehensive properties, difficulty in achieving nanofiber-reinforced scaffold structures, and limited effects, and achieve suitable hot water dissolution rate, excellent hydrophilicity, Improve the effect of low intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of nanofiber chitosan porous material, comprises the steps:

[0035] S1, dissolving chitosan in an aqueous acetic acid solution to prepare a chitosan solution, and defoaming for subsequent use;

[0036] S2. Uniformly dispersing polyvinyl alcohol-ethylene copolymer nanofibers in a solvent to prepare a nanofiber suspension;

[0037] S3. After blending and stirring the nanofiber suspension prepared in step S2 and the chitosan solution prepared in step S1 according to a preset volume ratio, ultrasonic dispersion is performed to obtain a nanofiber chitosan solution;

[0038] S4. Freeze-drying the nanofiber chitosan solution prepared in step S3 to obtain a nanofiber chitosan porous material.

[0039] In step S1, the volume fraction of acetic acid in the acetic acid aqueous solution is 1%; the concentration of the chitosan solution is 10-30 mg / mL.

[0040] In step S2, the polyvinyl alcohol-ethylene copolymer nanofibers are ...

Embodiment 1

[0050] The present embodiment provides a kind of preparation method of nanofiber chitosan porous material, comprises the steps:

[0051] S1, dissolving 2g of chitosan in 100mL of acetic acid aqueous solution with a volume fraction of 1%, prepares a chitosan solution, and defoams it for subsequent use;

[0052] S2. Uniformly disperse 2g of polyvinyl alcohol-ethylene copolymer nanofibers in a solvent mixed with water and isopropanol with a mass ratio of 1:1, and break them at high speed to prepare a nanofiber suspension; the nanofibers The mass percentage of polyvinyl alcohol-ethylene copolymer nanofibers in the fiber suspension is 2%;

[0053] Wherein, the polyvinyl alcohol-ethylene copolymer nanofiber is prepared by the following steps:

[0054] S21. Mix polyvinyl alcohol-ethylene copolymer and cellulose acetate butyrate evenly in a mass ratio of 1:4, melt extrude from a twin-screw extruder at a processing temperature of 170°C, and prepare composite fibers after drawing;

[...

Embodiment 2~5 and comparative example 1~2

[0061] Embodiment 2~5 and comparative example 1 provide a kind of preparation method of nanofiber chitosan porous material respectively, compared with embodiment 1, the difference lies in changing the nanofiber suspension and chitosan solution in step S3 volume ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com