Environment-friendly ignition harness and preparation method thereof

A kind of fuse and environment-friendly technology, applied in the direction of detonating cord, explosives, etc., can solve the problems such as the storage stability of biological enzymes to be discussed, and achieve the effect of high yield, low cost and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

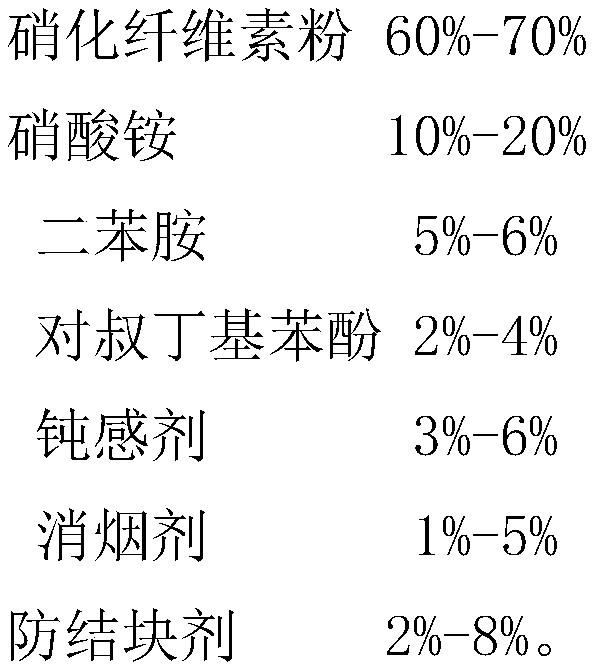

[0026] A kind of environmental protection fuse, each component and mass percentage are as follows:

[0027]

[0028] A kind of preparation method of environment-friendly fuse, concrete steps are as follows:

[0029] Step 1: Dissolve 125g of diphenylamine in 200ml of ethanol solvent, sonicate for 10 minutes with an ultrasonic pulverizer, then add 100g of p-tert-butylphenol, raise the temperature to 25°C, stir for 2 hours with a magnetic stirrer, and filter The product was collected, washed several times with ethanol, and finally the obtained product was dried at room temperature to constant weight for use.

[0030] Step 2: Mix 25g of vaseline, 50g of sodium bicarbonate, 50g of aluminum hydroxide, 50g of magnesium hydroxide, and 100g of polyvinylpyrrolidone with a glass rod according to mass percentage, and sieve through a 200-mesh copper sieve to collect the mixed medicine for later use.

[0031] Step 3: Mix the product obtained in Step 1 and Step 2 with 500g of ammonium ni...

Embodiment 2

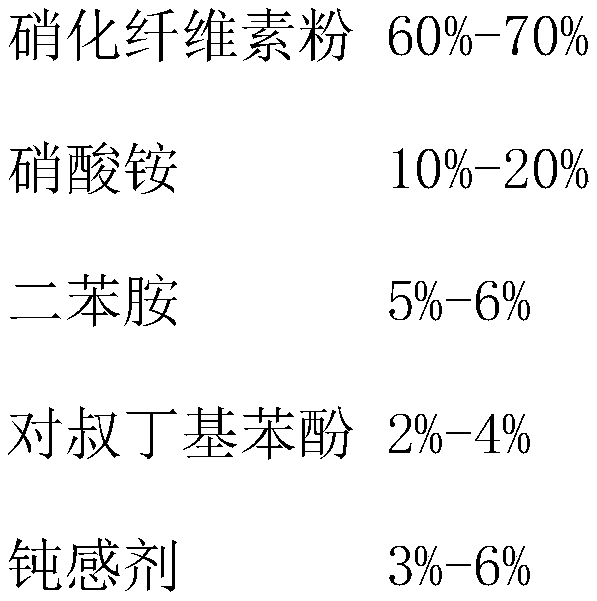

[0036] A kind of environmental protection fuse, each component and mass percentage are as follows:

[0037]

[0038]

[0039] A kind of preparation method of environment-friendly fuse, concrete steps are as follows:

[0040] Step 1: Dissolve 27.5g of diphenylamine in 150ml of ethanol solvent, sonicate for 20 minutes with an ultrasonic pulverizer, then add 15g of p-tert-butylphenol, raise the temperature to 30°C, and stir for 3 hours with a magnetic stirrer. The product was collected by filtration, washed several times with ethanol, and finally the obtained product was dried at room temperature to constant weight for use.

[0041] Step 2: Mix 20g of synthetic resin, 5g of aluminum hydroxide, 7.5g of magnesium hydroxide, 10g of ammonium octamolybdate, 15g of polyvinyl alcohol and 10g of sodium dodecylbenzenesulfonate with a glass rod according to the mass percentage, and use a 200-mesh Sieve through a copper sieve to collect the mixed medicine for later use.

[0042] Ste...

Embodiment 3

[0047] A kind of environmental protection fuse, each component and mass percentage are as follows:

[0048]

[0049]

[0050] A kind of preparation method of environment-friendly fuse, concrete steps are as follows:

[0051] Step 1: Dissolve 150g of diphenylamine in 250ml of ethanol solvent, sonicate for 30 minutes with an ultrasonic pulverizer, then add 50g of p-tert-butylphenol into it, raise the temperature to 40°C, stir with a magnetic stirrer for 4 hours, and filter The product was collected, washed several times with ethanol, and finally the obtained product was dried at room temperature to constant weight for use.

[0052] Step 2: Mix 25g vaseline, 50g synthetic resin, 75g sodium bicarbonate, 50g ammonium octamolybdate, 50g sodium dodecylbenzenesulfonate, 50g polyvinylpyrrolidone and 50g polyvinyl alcohol with a glass rod by mass percentage, Sieve with a 200-mesh copper sieve to collect the mixed medicine for later use.

[0053] Step 3: Mix the product obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com