Special efficient coagulant for strongly-acidic antimony-containing wastewater

A strong acid and coagulant technology, applied in water pollutants, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of complicated operation and high treatment cost, and achieve simple storage conditions, The effect of long storage time and fast precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the high-efficiency coagulant specially used for strongly acidic antimony-containing wastewater is as follows:

[0024] Step 1: Take a 250mL three-necked flask, add 100mL of absolute ethanol, 20mL of ultrapure water, and 1.5mL of ammonia water in sequence, then place the three-necked flask in a constant temperature water bath at 30°C, connect it to a mechanical stirrer, and keep Stir the mixed solution in the three-neck flask for 10 min at a low speed (100 r / min), so that absolute ethanol, ultrapure water, and ammonia water are mixed evenly.

[0025] Step 2: After stirring, adjust to high speed (1000r / min), pipette 4mL orthoethyl silicate (TEOS) dropwise into the three-necked flask, and feed nitrogen (N 2 ) for 30min, and then adjusted to medium speed (600r / min) to stir the mixed solution in the three-necked flask for 20h.

[0026] Step 3: After the stirring, the mixture in the three-necked flask was subjected to low-temperature centrifugation...

Embodiment 2

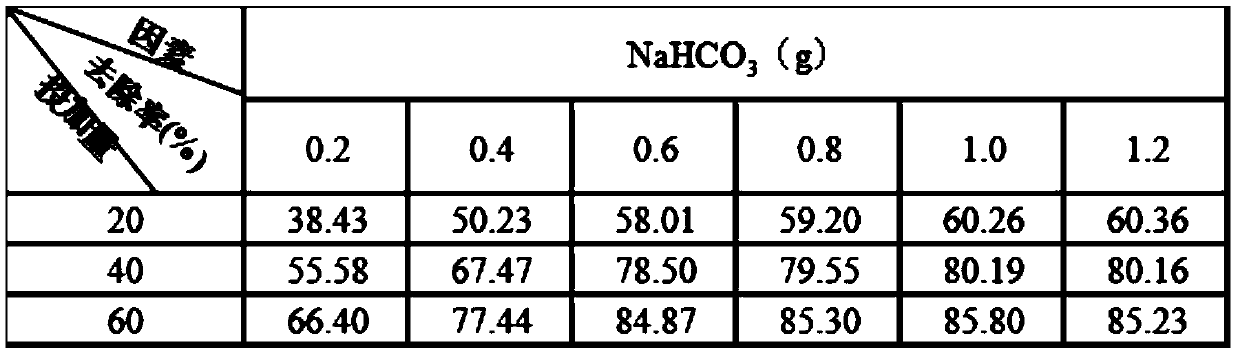

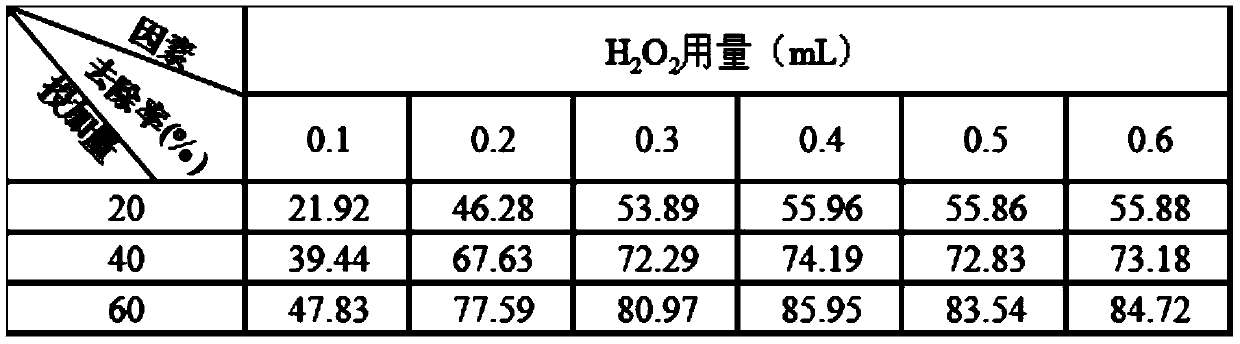

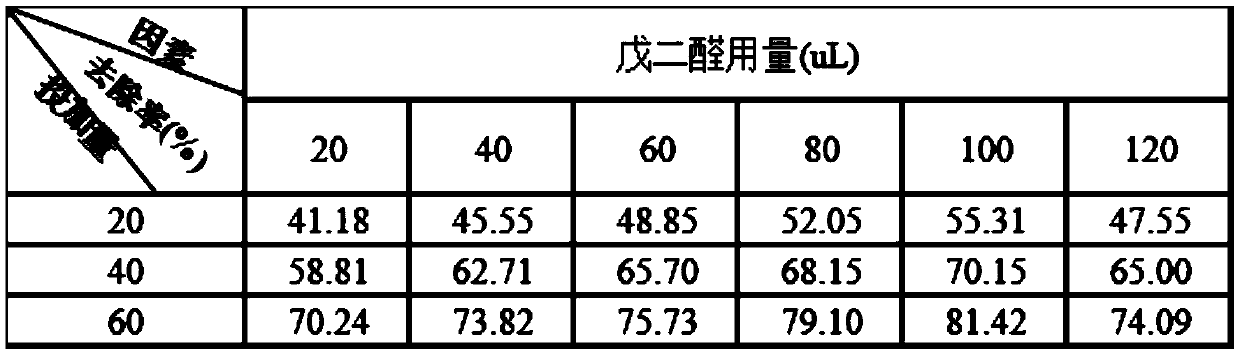

[0032] In the high-efficiency coagulant specially used in strongly acidic antimony-containing wastewater provided by the invention, sodium bicarbonate (NaHCO 3 ), hydrogen peroxide (H 2 o 2 ), the addition of glutaraldehyde will affect the performance of removing antimony ions. The experiment to determine the addition amount employed in Example 1 is as follows.

[0033] Prepare a strongly acidic (pH=1-3) water sample containing antimony with a concentration of 10mg / L. Measure 200mL each time and add it to a 250mL beaker. Six beakers form a group, and three groups of beakers are used as a single factor experiment. 20, 40, and 60 mg of the high-efficiency coagulant (TGSSG) specially used for strongly acidic antimony-containing wastewater were added to three groups of beakers in each single factor experiment.

[0034] The coagulation is divided into three stages: stirring at a stirring speed of 300r / min for 5min; stirring at a stirring speed of 100r / min for 10min; separation a...

Embodiment 3

[0043] In order to prove the advantages of the high-efficiency coagulant (TGSSG) specially used for strongly acidic antimony-containing wastewater in the treatment of strongly acidic antimony-containing wastewater, it was compared with existing conventional coagulants (ferric chloride, polyferric sulfate, polyaluminum sulfate), magnetic coagulant (magnetic chitosan), and in strongly acidic (pH=1-3 range) antimony-containing water samples, the removal ability of antimony ions was compared. The initial concentration of antimony ions is 10mg / L. The results are shown in Table 4.

[0044]

[0045] Table 4

[0046] Obviously, compared with existing conventional coagulant (ferric chloride, polyferric sulfate, polyaluminum sulfate), magnetic coagulant (magnetic chitosan), the high-efficiency coagulation that is specially used in strongly acidic antimony-containing wastewater TGSSG has greatly improved the removal effect of antimony ions in strongly acidic (pH=1-3) antimony-contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com