Heat shrinkable film and preparation method and application thereof

A heat-shrinkable film and masterbatch technology, used in applications, other household appliances, chemical instruments and methods, etc., can solve the problems of inability to scan the product label, poor toughness of POF shrink film, slow shrinkage speed, etc., to achieve shrinkage speed. Fast, reduce the rate of breakage, the effect of low shrinkage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

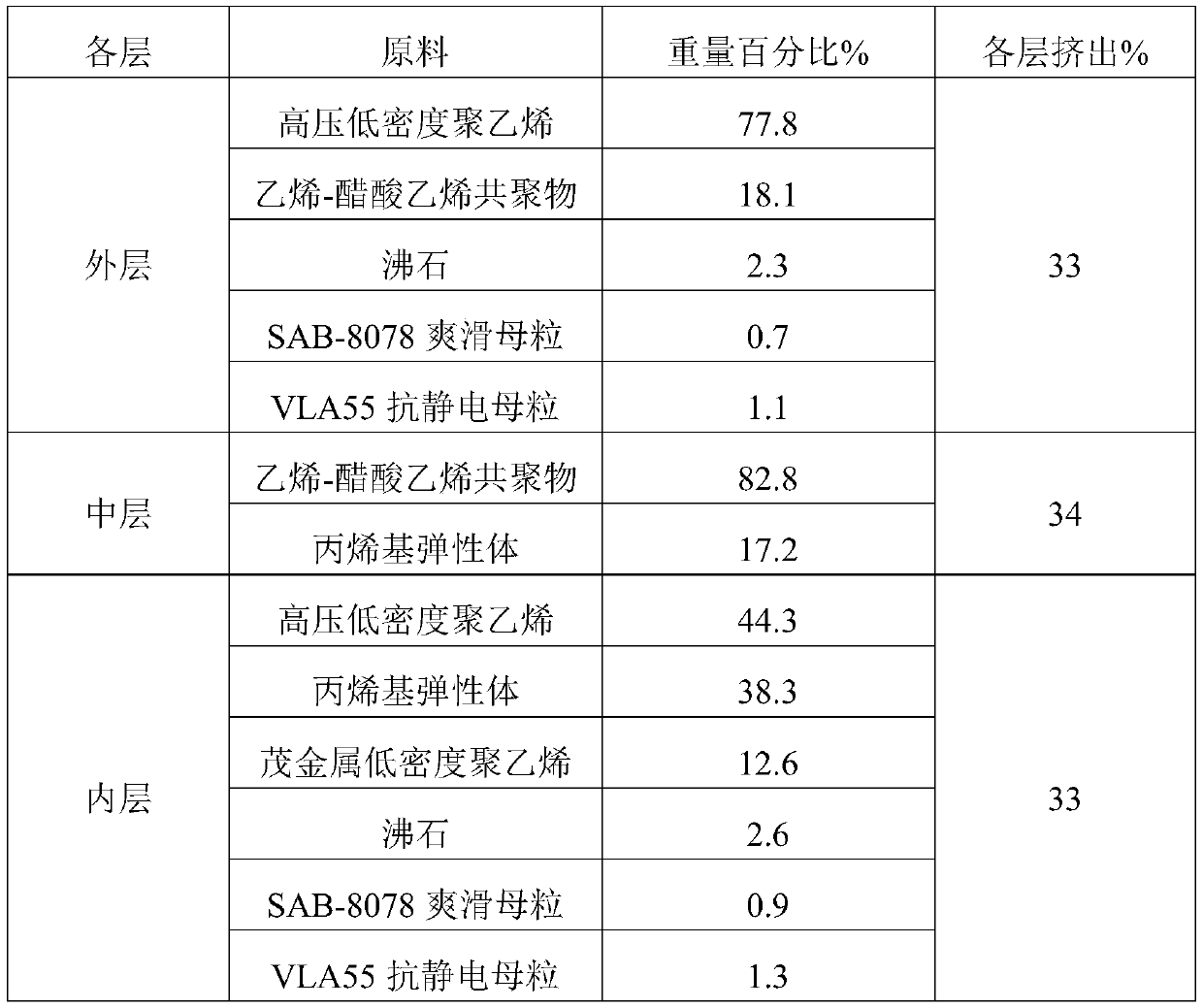

[0058] The heat-shrinkable film of this embodiment has a three-layer structure, which is an outer layer, a middle layer and an inner layer respectively. The weight percentages between the materials of the three layers are respectively: 33% for the outer layer, 34% for the middle layer, and 33% for the inner layer; The components are shown in Table 1 below:

[0059] Table 1

[0060]

[0061] The melt index of the high-pressure low-density polyethylene in the outer layer component is 0.25g / 10min, and the density is 0.924g / cm 3 , specifically preferred 2420D produced by China Sea Shell Petrochemical Co., Ltd.; the melt index of the ethylene-vinyl acetate copolymer is 0.25g / 10min, and the density is 0.930g / cm 3 , the vinyl acetate (VA) content is 12%, specifically the 3135 that the preferred U.S. DuPont company produces.

[0062] The melt index of the ethylene-vinyl acetate copolymer described in the middle layer component is 1.5g / 10min, and the density is 0.930g / cm 3 , the ...

Embodiment 2

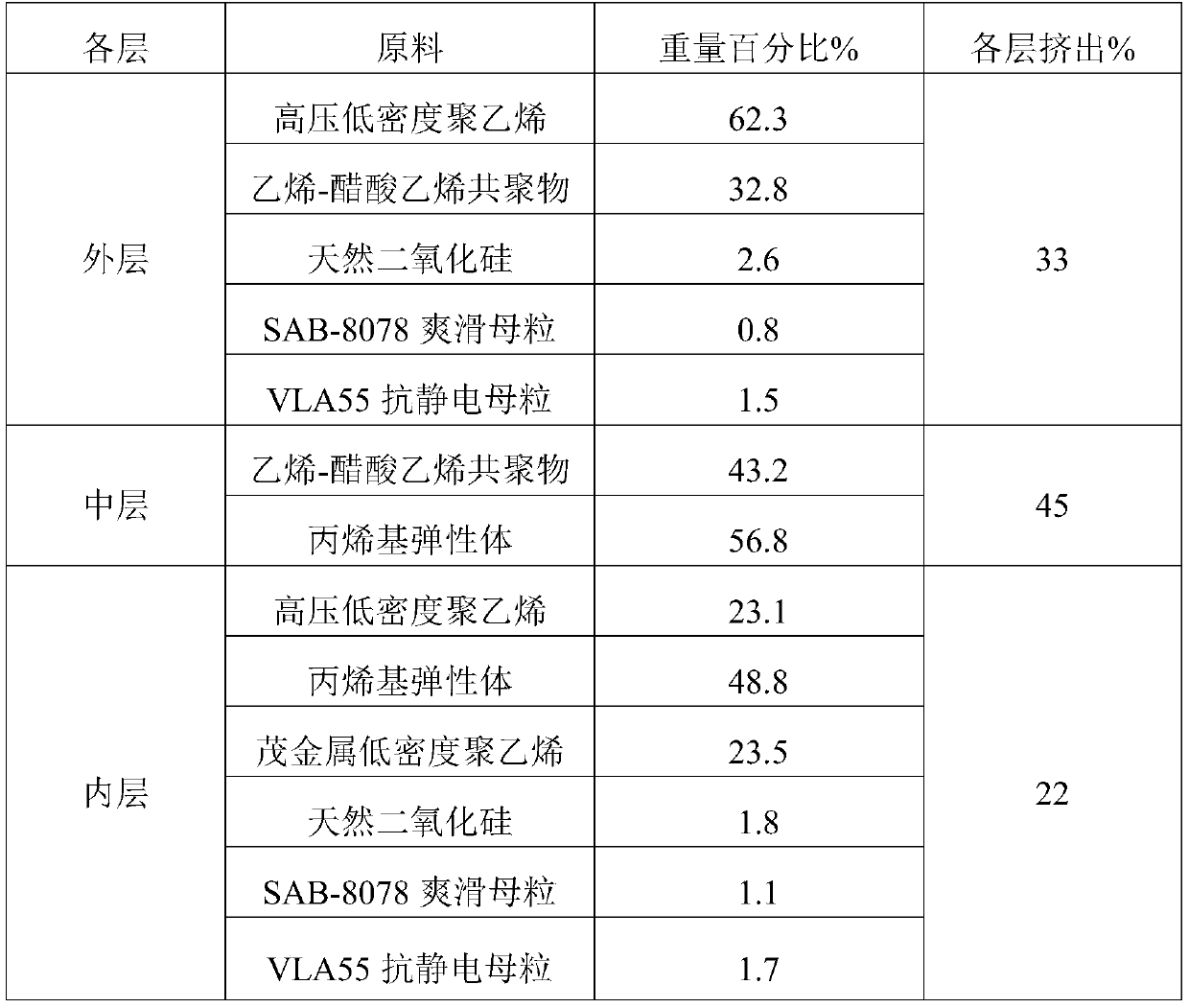

[0075] The heat-shrinkable film of this embodiment has a three-layer structure, which is an outer layer, a middle layer and an inner layer respectively. The weight percentages between the materials of the three layers are respectively: 33% for the outer layer, 45% for the middle layer, and 22% for the inner layer; The components are shown in Table 3 below:

[0076] table 3

[0077]

[0078] Except that the anti-adhesive masterbatch is natural silica, the melt index, density and manufacturer of the components of each layer of the heat shrinkable film in this example are the same as in Example 1. The preparation method of the heat-shrinkable film of this embodiment is the same as that of Example 1, and the process parameters of the extruder are as shown in Table 4:

[0079] Table 4

[0080] temperature zone 1 Zone 2 District 3 District 4 District 5 pressure (bar) outer layer 141 145 147 143 142 182-238 Middle 135 138 143 141 137 16...

Embodiment 3

[0082] The heat-shrinkable film of this embodiment has a three-layer structure, which is an outer layer, a middle layer and an inner layer respectively. The weight percentages between the materials of the three layers are respectively: 25% for the outer layer, 50% for the middle layer, and 25% for the inner layer; The composition components are shown in Table 5 below:

[0083] table 5

[0084]

[0085]

[0086] Except that the anti-adhesive masterbatch is synthetic silica, the melt index, density and manufacturer of the components of each layer of the heat shrinkable film in this example are the same as those in Example 1. The preparation method of the heat-shrinkable film of this embodiment is the same as that of Example 1, and the process parameters of the extruder are as shown in Table 6:

[0087] Table 6

[0088] temperature zone 1 Zone 2 District 3 District 4 District 5 pressure (bar) outer layer 141 145 147 143 142 172-218 Mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com