A method for controlling the solidification temperature of alloy melt based on cooling rate

A technology of solidification temperature and cooling rate, which is applied in the field of alloy melt solidification temperature regulation based on cooling rate, can solve the problems of lack of effective technical methods and lack of understanding of the supercooled solidification temperature of alloy melt, and achieve controllability and The effect of strong repeatability, low cost and high technical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

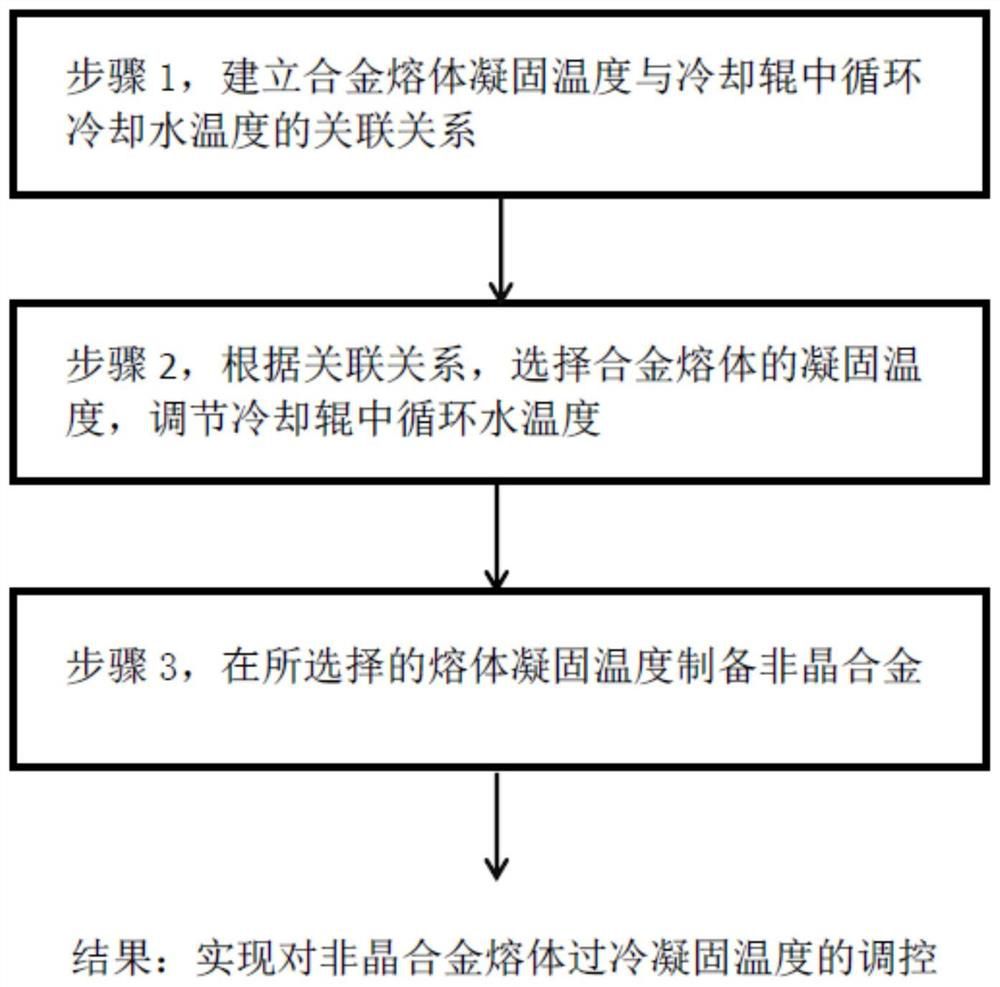

[0034] combine figure 1 , a preferred embodiment of the method for regulating the solidification temperature of the alloy melt based on the cooling rate proposed by the present invention includes the following specific steps:

[0035] Step 1, establishing the relationship between the solidification temperature of the alloy melt and the temperature of the circulating cooling water in the cooling roll: (1) At a fixed melt casting temperature, the alloy melts are respectively cast to different temperatures of the circulating cooling water (10-35°C) (2) in-situ measurement of the solidification temperature of the amorphous alloy melt on the copper sleeve of the high-speed rotating cooling roll to obtain the solidification temperature of the melt at different cooling water temperatures; ( 3) Establish the correlation between the solidification temperature of the melt and the temperature of the circulating cooling water in the cooling roll;

[0036] Step 2, select the solidificatio...

Embodiment 1

[0040] to adopt Fe 84 P 2 Si 2 B 12 An amorphous solid alloy thin strip is taken as an example (the subscript number in the chemical formula is at%), and the amorphous alloy thin strip is prepared by a high-speed planar flow continuous casting method commonly used in this field. The specific operation steps of the alloy melt solidification temperature regulation and control method based on the cooling rate proposed by the present invention are as follows:

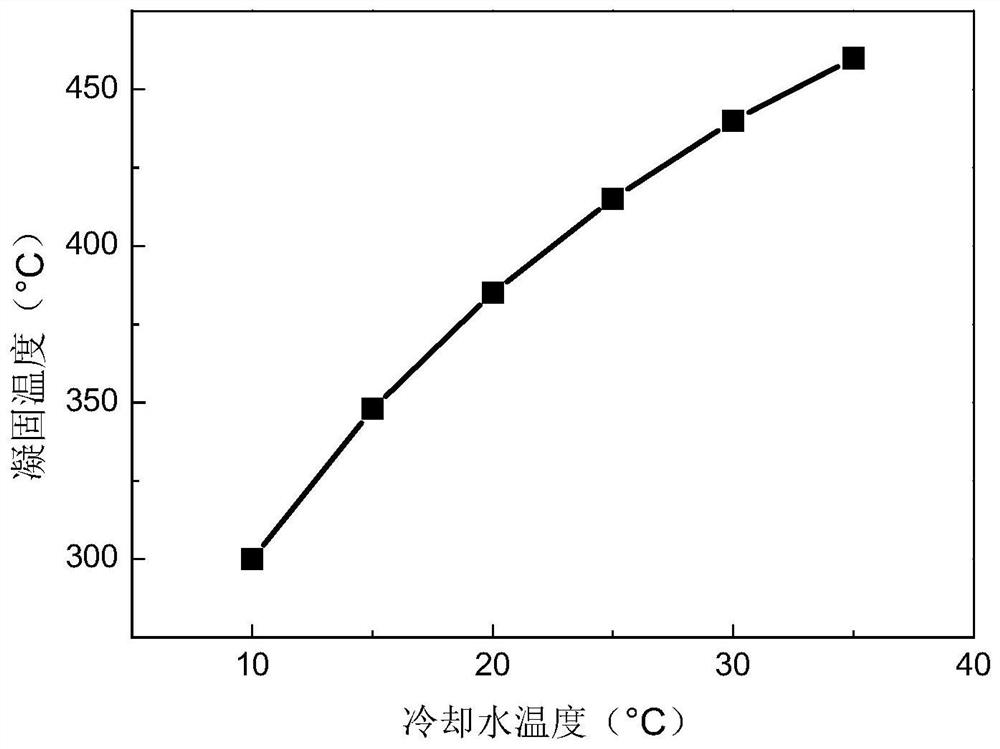

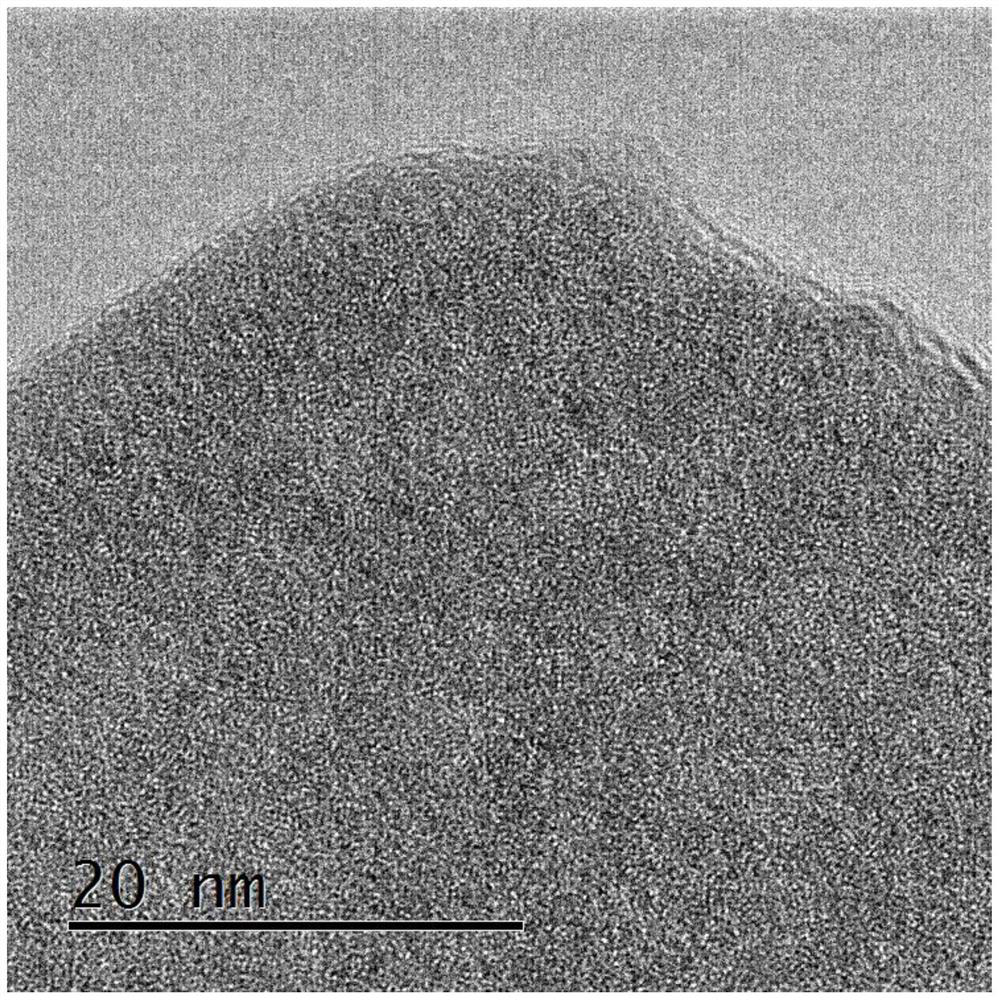

[0041] Step 1, establishing the relationship between the solidification temperature of the alloy melt and the temperature of the circulating cooling water in the cooling roll: (1) at a fixed melt casting temperature of 1300°C, Fe 84 P 2 Si 2 B 12 The alloy melts are respectively cast on the surface of copper sleeves of high-speed rotating cooling rolls with different cooling water temperatures (cooling water temperature is 10-35°C, such as 10°C, 15°C, 20°C, 25°C, 30°C, 35°C), and prepared into Amorphous alloy thin st...

Embodiment 2

[0046] to adopt Fe 84 P 2 Si 2 B 12 An amorphous solid alloy thin strip is taken as an example (the subscript number in the chemical formula is at%), and the amorphous alloy thin strip is prepared by a high-speed planar flow continuous casting method commonly used in this field. The specific operation steps of the alloy melt solidification temperature regulation and control method based on the cooling rate proposed by the present invention are as follows:

[0047] Step 1, establishing the relationship between the solidification temperature of the alloy melt and the temperature of the circulating cooling water in the cooling roll: (1) at a fixed melt casting temperature of 1300°C, Fe 84 P 2 Si 2 B 12 The alloy melts are respectively casted on the surface of the copper sleeve of the cooling roll with different cooling water temperatures (10-35°C, such as 10°C, 15°C, 20°C, 25°C, 30°C, 35°C) to prepare amorphous Alloy thin strip; (2) Use a laser infrared thermometer (model:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com