Linkage type magnetic separation device for rare earth permanent magnet material

A rare earth permanent magnet and magnetic separation device technology, which is applied in magnetic separation, solid separation, grain processing, etc., can solve the problems of time-consuming, labor-intensive, waste of rare earth resources, etc., and achieve the effect of reducing the unit volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

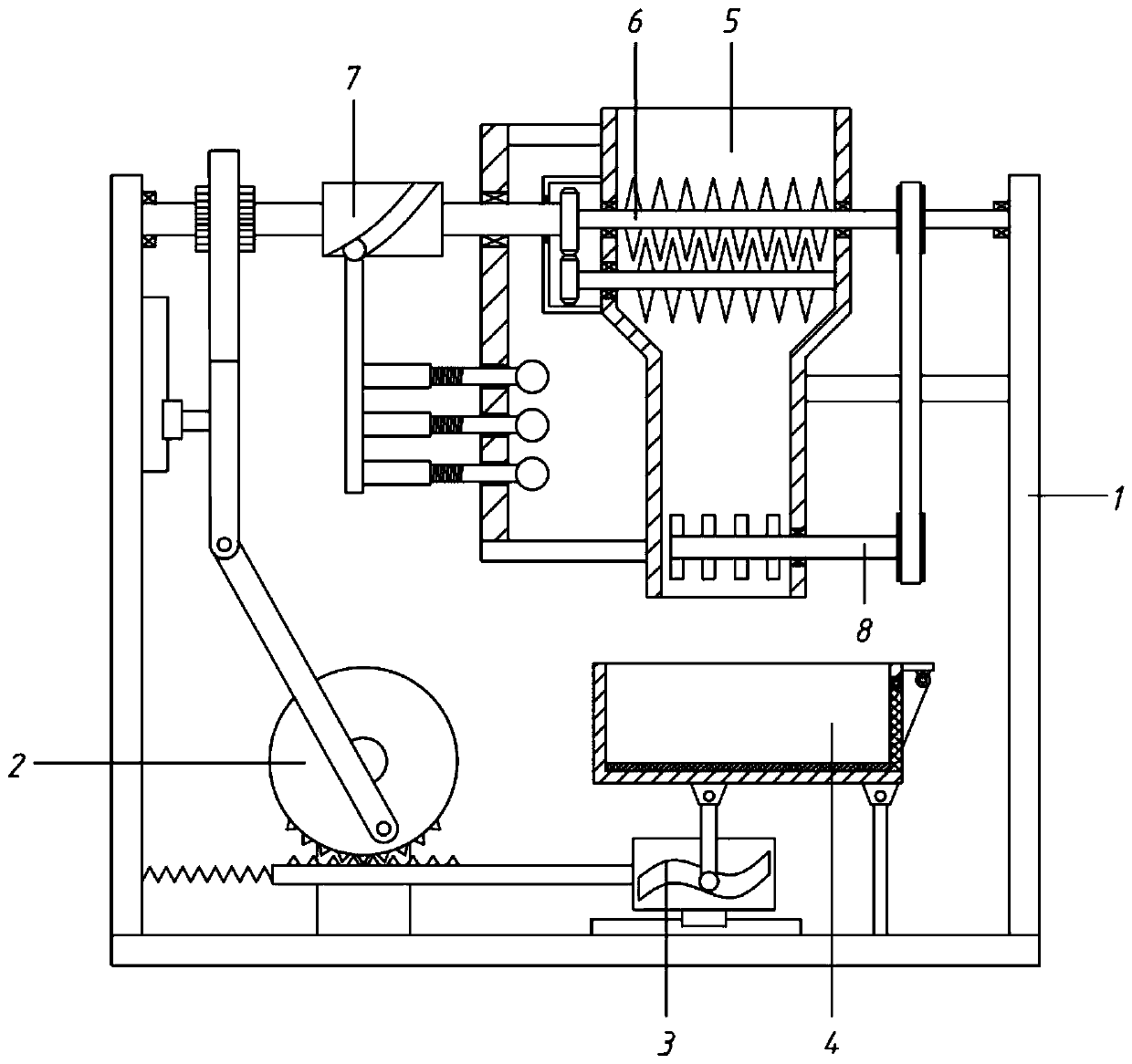

[0058] A linkage type magnetic separation device for rare earth permanent magnet materials, comprising a frame 1, a drive assembly 2, a housing 5, a crushing assembly 6, a shaking assembly 3 and a magnetic separation box 4;

[0059] The frame 1 includes a base 101, a left side plate 102 and a right side plate 103 arranged at the left and right ends of the base 101;

[0060] The driving assembly 2 is arranged on the left part of the base 101; the housing 5 is arranged above the right part of the base 101, and is fixedly connected to the left side of the right side plate 103 through the support frame 104; the housing 5 is divided into an upper crushing chamber 501 and a lower feeding chamber. Cavity 502; crushing chamber 501 is provided with a crushing assembly 6; the magnetic separation box 4 is arranged below the housing 5, and the bottom of the magnetic separation box 4 is provided with a shaking assembly 3; the driving assembly 2 drives the crushing assembly 6 and the shaking...

Embodiment 2

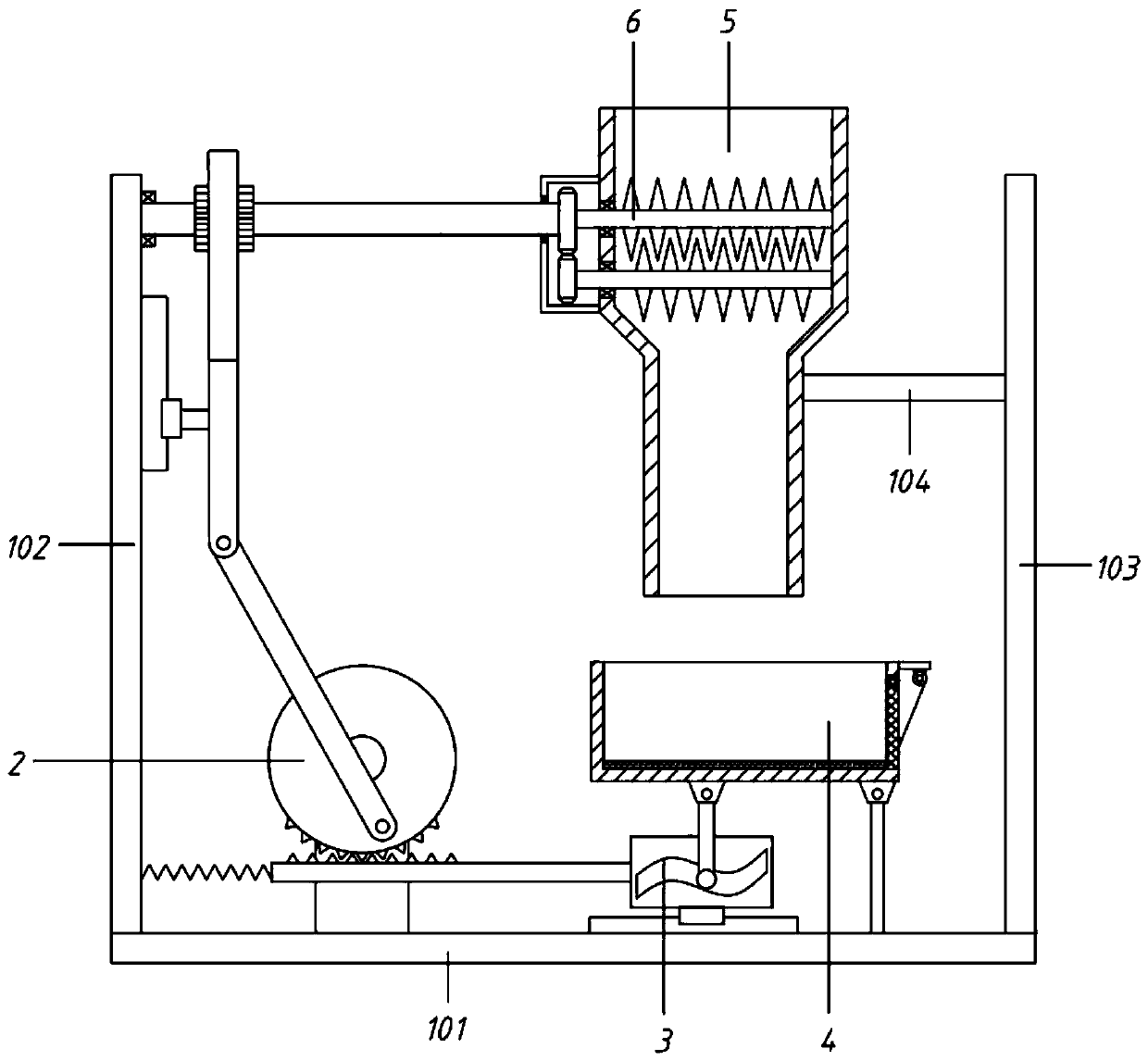

[0062] A linkage type magnetic separation device for rare earth permanent magnet materials, comprising a frame 1, a drive assembly 2, a housing 5, a crushing assembly 6, a shaking assembly 3 and a magnetic separation box 4;

[0063] The frame 1 includes a base 101, a left side plate 102 and a right side plate 103 arranged at the left and right ends of the base 101;

[0064] The driving assembly 2 is arranged on the left part of the base 101; the housing 5 is arranged above the right part of the base 101, and is fixedly connected to the left side of the right side plate 103 through the support frame 104; the housing 5 is divided into an upper crushing chamber 501 and a lower feeding chamber. Cavity 502; crushing chamber 501 is provided with a crushing assembly 6; the magnetic separation box 4 is arranged below the housing 5, and the bottom of the magnetic separation box 4 is provided with a shaking assembly 3; the driving assembly 2 drives the crushing assembly 6 and the shaking...

Embodiment 3

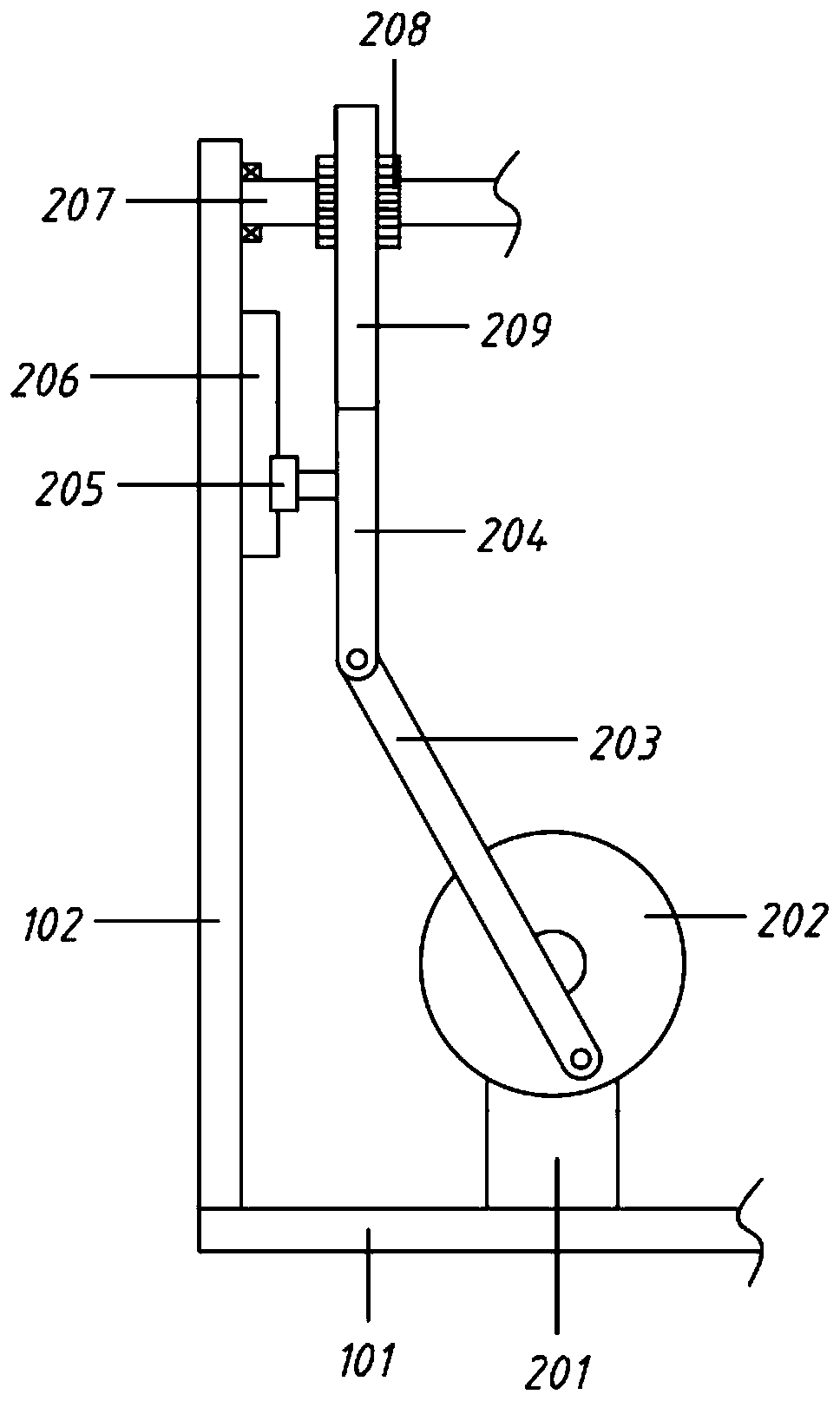

[0077] On the basis of embodiment 2,

[0078] A vibration material assembly 7 is also provided; the vibration material assembly 7 includes a support plate 701, a cylindrical cam 702, a roller 703, a third rod 704, a fourth rod 705 and a collision end 706;

[0079] The left side of the housing 5 is provided with a support plate 701, the upper and lower ends of the support plate 701 are bent to the right and fixedly connected to the housing 5; the first rotating shaft 206 passes through and rotates to connect with the supporting plate 701; the first rotating shaft 206 is equipped with a cylindrical cam 702 , the cylindrical cam 702 is arranged on the left side of the support plate 701; the cylindrical cam 702 is matched with a roller 703, and the roller 703 is connected downward with the third rod 704, and the third rod 704 is connected with the fourth rod 705 to the right, and the fourth rod 705 wears Through the support plate 701 and equipped with a collision end 706.

[0080...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com