Bulk phase catalyst and preparation method thereof, and hydrogenation catalyst containing bulk phase catalyst

A bulk catalyst, hydrogenation reaction technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as pollution of the environment, achieve high specific surface area, and improve catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a kind of preparation method of bulk catalyst, and this preparation method comprises the steps:

[0036]Step 1, preparing a mixed liquid from a compound containing Group VIII elements and a compound containing Group VIB elements, adjusting the pH of the mixed liquid to 6-11, and then adding a surfactant;

[0037] Step 2, placing the mixed solution obtained in step 1 after adding the surfactant in an airtight container for reaction, the reaction time is at least 10 minutes, and the reaction temperature is 5-75°C; and

[0038] Step 3, heating the mixed solution to 80-200° C. for reaction, the reaction time is at least 1 hour, filtering and drying to obtain the bulk catalyst.

[0039] Wherein, in step 1, the compound containing Group VIII elements is preferably a compound containing cobalt and / or nickel, more preferably a compound containing nickel; the compound containing Group VIB elements is preferably a compound containing molybdenum and / or tungs...

Embodiment 1

[0052] Weigh 15.51g of nickel nitrate, 9.42g of ammonium heptamolybdate, and 7.19g of ammonium metatungstate, and add them into 160g of water to prepare a reaction solution. In the solution, ammonia water with a mass concentration of 25% was added dropwise until the pH value of the mixed solution was 9, and then 1.0 g of Tween-80 was added. The system was placed in a closed reactor, reacted at 35°C for 2 hours, then heated up to 150°C, reacted for 2 hours, then cooled, filtered, washed with water, and the filter cake was dried at 120°C for 4 hours. A bulk catalyst is obtained.

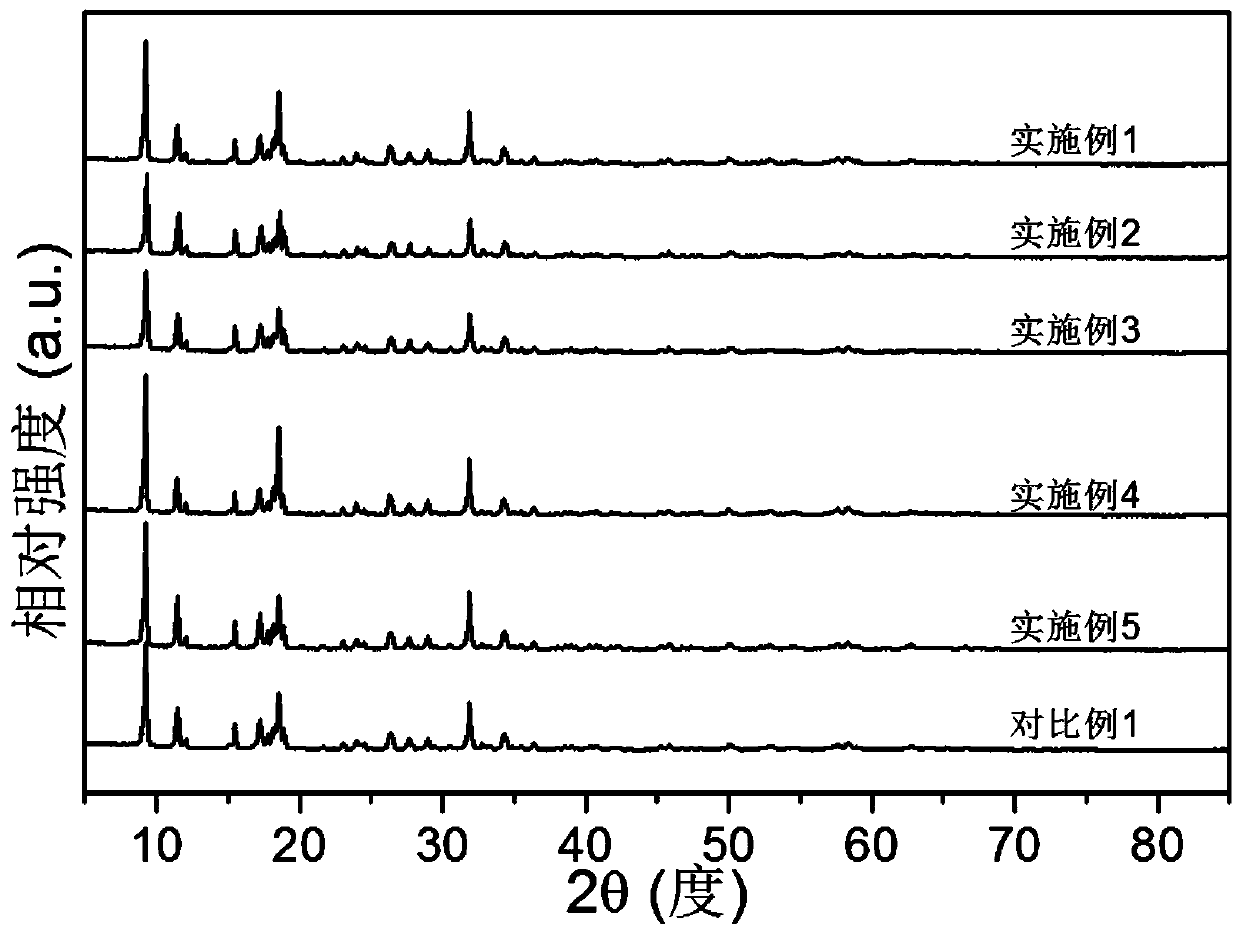

[0053] In this example, during the reaction of the system at 35°C, bulk catalyst seeds are gradually formed, and the XRD pattern of the seeds is shown in figure 1 As shown, the mixture was gradually precipitated from a transparent solution state, and the solution became cloudy, which also indicated that there was a chemical reaction in this process. According to the XRD characterization results, it c...

Embodiment 2

[0056] Weigh 12.03g of basic nickel carbonate, 0.57g of basic cobalt carbonate, 2.35g of ammonium heptamolybdate, and 3.32g of tungstic acid, and add them into 160g of water to prepare a suspension. In the suspension, dilute nitric acid with a mass concentration of 15% was added dropwise until the pH of the mixture was 7, and then 0.8 g of polyethylene glycol-400 and 0.4 g of polyethylene glycol-1000 were added. The system was placed in a closed reactor, reacted at 45°C for 3 hours, then heated to 120°C, reacted for 8 hours, then cooled, filtered, washed with water, and the filter cake was dried at 120°C for 4 hours. A bulk catalyst is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com