Metal-doped ceramsite catalyst, preparation method and applications thereof

A catalyst and metal-type technology, which is applied in the field of doped metal-type ceramsite catalyst and its preparation, can solve the problems of affecting the catalytic effect and popularization and application, uneven distribution of active components, and difficult industrial production of catalysts, etc. Dissolution, low loss rate of active ingredients, and the effect of solving uneven distribution of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

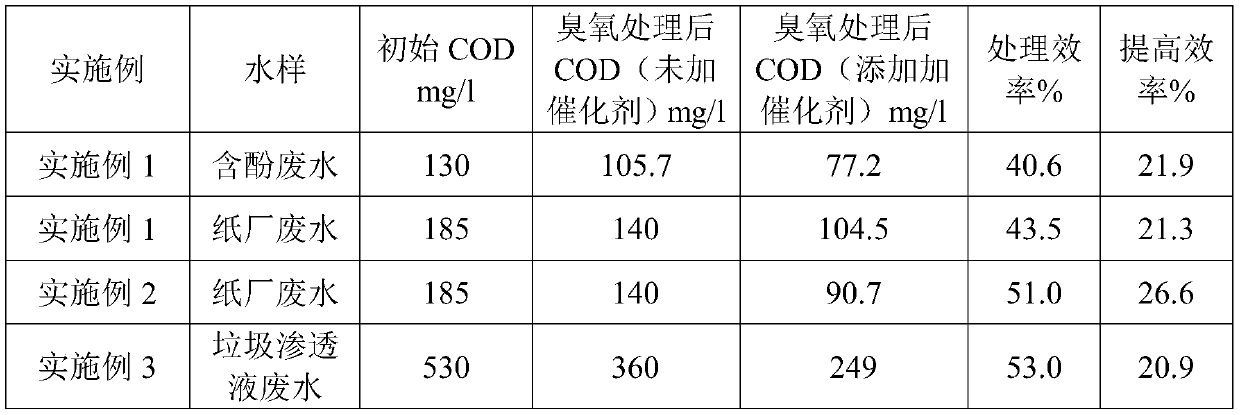

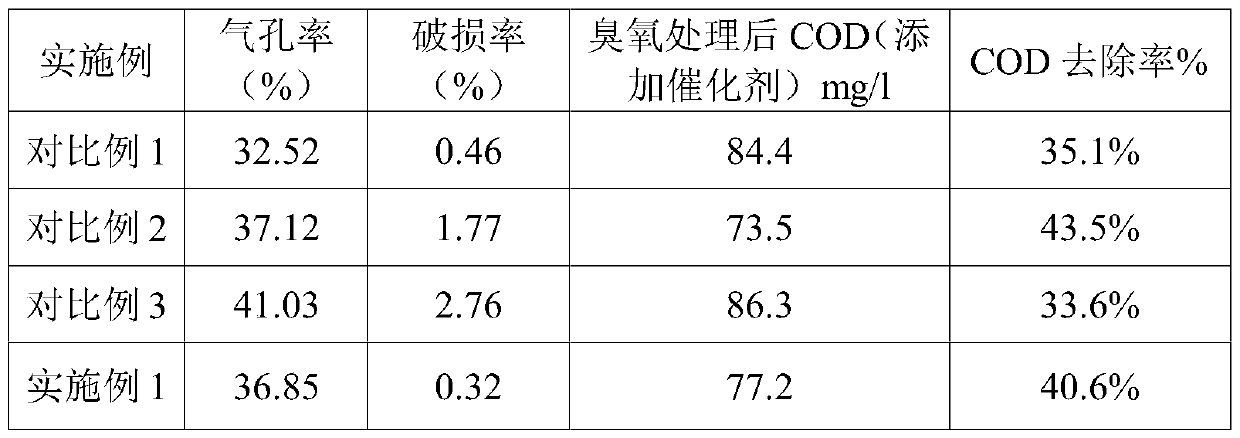

Examples

preparation example Construction

[0051] A method for preparing a doped metal-type ceramsite catalyst, comprising:

[0052] Material preparation step: take pottery clay, pore-forming agent, vermiculite, fluxing agent of formula quantity and grind them to below 200 orders respectively, obtain pottery matrix component; The pottery clay in pottery matrix component is divided into two parts, counted as : The first part clay and the second part clay;

[0053] Metal salt treatment steps: Weigh the metal salt of the formula amount, divide the metal salt into two parts, which are respectively recorded as the first part of metal salt and the second part of metal salt; dissolve the first part of metal salt in water to obtain a metal salt solution, and divide the second part of metal salt into Two parts of the metal salt are ground into a dry powder below 50 meshes to obtain a metal salt dry powder;

[0054] The preparation steps of the ceramsite core: take the first part of pottery clay, and prepare a ceramsite core wi...

Embodiment 1

[0066] A kind of doped metal type ceramsite catalyst, comprises the metal salt of 80g, 350g pottery matrix component;

[0067] Among them, the pottery matrix components include: pottery clay 300g, starch 32g, vermiculite 4g, magnesium carbonate 8g, calcium carbonate 6g.

[0068] In this embodiment, the metal-doped ceramsite catalyst is prepared by the following method:

[0069] Material preparation step: take pottery clay, starch, vermiculite, magnesium carbonate, calcium carbonate of formula quantity, and grind them respectively to below 200 mesh, obtain pottery matrix component; Divide pottery clay in pottery matrix component into two parts, the first One part of pottery clay 100g, the second part of pottery clay 200g;

[0070] Metal salt treatment steps: Dissolve 30g of ferrous sulfate heptahydrate and 15g of manganese sulfate in 70ml of water to form a metal salt solution; then grind 20g of ferrous sulfate heptahydrate and 15g of manganese sulfate into a metal salt dry po...

Embodiment 2

[0077] A kind of doped metal type ceramsite catalyst, comprises the metal salt of 200g, 350g pottery matrix component;

[0078] Among them, the pottery matrix components include: pottery clay 300g, coal powder 32g, vermiculite 4g, magnesium carbonate 8g, calcium carbonate 6g.

[0079] Prepare the metal-doped ceramsite catalyst of the present embodiment according to the method of Example 1, the difference is:

[0080] Metal salt treatment steps: Dissolve 30g of ferrous sulfate heptahydrate and 25g of manganese sulfate in 70ml of water to form a metal salt solution; then grind the remaining 95g of ferrous sulfate heptahydrate and 50g of manganese sulfate into dry powder of metal salt below 50 mesh .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com