Electrified heating regenerated active carbon adsorption purification system and electrified heating regenerated active carbon adsorption purification method

An activated carbon adsorption and purification system technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of low quality of recycled materials, large post-processing load, and large damage to activated carbon, so as to avoid deterioration of recycled materials, Low processing load and low post-processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

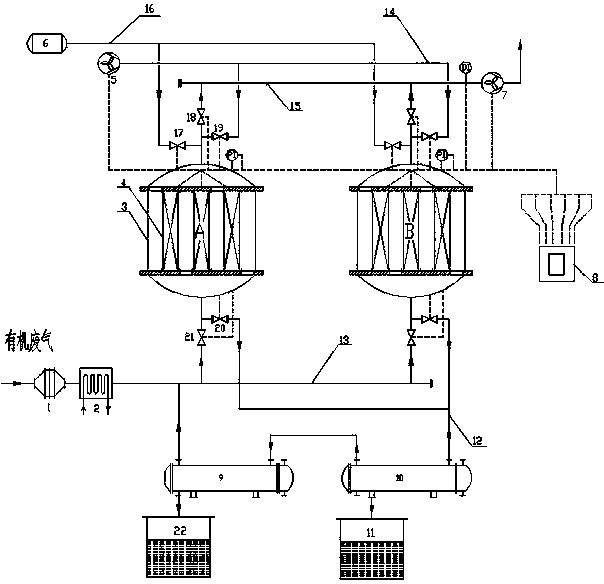

[0036] Example 1 (Nitrogen blanket protection condensation recovery treatment)

[0037] Such as figure 1As shown, an activated carbon adsorption and purification system for heating and regenerating through electricity includes a filter 1, a cooler 2, two activated carbon adsorbers 3, an exhaust fan 7, a post-processing system, a cooling fan 5, a nitrogen source 6, a control system 8, Adsorption pipeline 13, desorption pipeline 12, exhaust pipeline 15, cooling pipeline 14, purge pipeline 16; described activated carbon adsorber shell is provided with pipeline connection port, is communicated with each pipeline through valve, and described pipeline connection port is respectively set At the opposite ends of the activated carbon adsorber, one end is provided with a waste gas inlet and a desorption gas outlet, and the other end is respectively provided with a purge gas inlet, a purified gas outlet and a cooling gas inlet, and the adsorption pipeline 13 is connected to the filter 1 ...

Embodiment 2

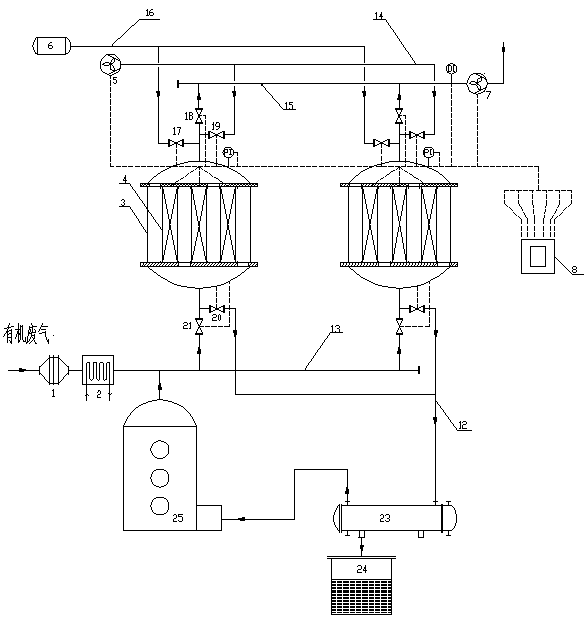

[0047] Example 2 (Oxygen-poor Protection Absorption and Recovery Treatment)

[0048] An activated carbon adsorption and purification system for regeneration by heating with electricity in this embodiment is as follows: figure 2 As shown, the post-processing system of this embodiment includes a condenser B23, a liquid storage tank B24 and an absorption tower 25, the liquid outlet of the condenser B23 is connected to the liquid storage tank B24, and the gas outlet of the condenser B23 is connected to the intake of the absorption tower 25 The air inlet of the condenser B23 communicates with the end of the desorption pipeline 12, and the gas outlet of the absorption tower 25 communicates with the adsorption pipeline 13.

[0049] The method of using the above-mentioned organic waste gas adsorption treatment system to absorb and recover organic waste gas, wherein the step (3) desorption and recovery process adopts oxygen-poor protection with an oxygen volume content of less than 5%...

Embodiment 3

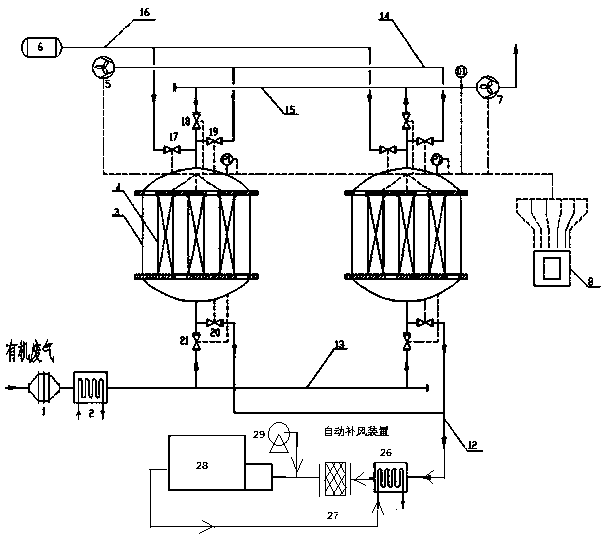

[0050] Embodiment 3 (air purging oxidation treatment)

[0051] An activated carbon adsorption and purification system for regeneration by heating with electricity in this embodiment is as follows: image 3 As shown, wherein the aftertreatment system includes a heat exchanger 26, a flame arrester 27, an oxidation furnace 28 and an automatic air supply device 29, the cold source air inlet of the heat exchanger 26 communicates with the end of the desorption pipeline 12, and the heat exchanger The cold source air outlet of 26 is connected to the air inlet of flame arrester 27, the air outlet of flame arrester 27 is connected to the air inlet of oxidation furnace 28, the air outlet of oxidation furnace 28 is connected to the heat source air inlet of heat exchanger 26, and the oxidation tail gas is transferred from the heat exchange The heat source air outlet of the device 26 is discharged, and the automatic air replenishment device 29 is arranged at the air inlet of the oxidation f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com