Active carbon adsorption purification system and active carbon adsorption purification method adopting vacuum electric heating regeneration

An activated carbon adsorption and purification system technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high regeneration energy consumption, large condensation load, incomplete regeneration, etc., and achieve low regeneration energy consumption and processing load Low maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

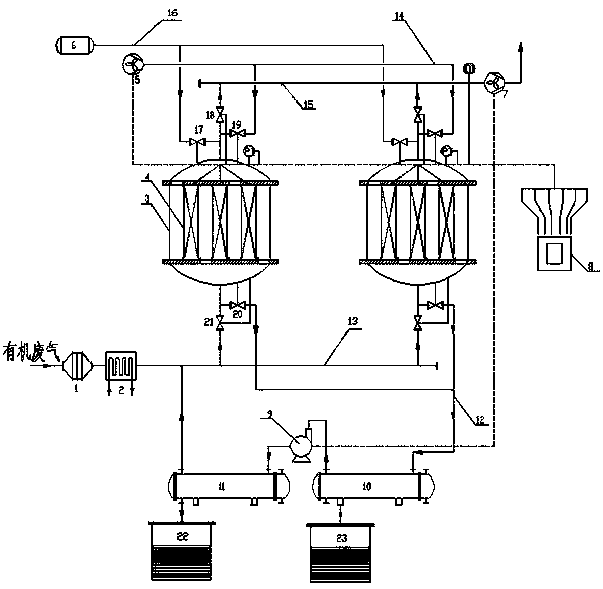

[0043] Example 1 (vacuum condensation recovery treatment)

[0044] Such as figure 1 As shown, the activated carbon adsorption and purification system and method using vacuum electrothermal regeneration include a filter 1, a cooler 2, two activated carbon adsorbers 3, an exhaust fan 7, a post-processing system, a cooling fan 5, an air source 6, and a control system 8 , adsorption pipeline 13, desorption pipeline 12, exhaust pipeline 15, cooling pipeline 14, purge pipeline 16; Described activated carbon adsorber shell is provided with pipeline connection port, communicates with each pipeline through valve, and described pipeline connection port is respectively It is arranged at opposite ends of the activated carbon adsorber, one end is provided with waste gas inlet and desorption gas outlet, and the other end is respectively provided with purge gas inlet, purified gas outlet and cooling gas inlet, and the adsorption pipeline 13 is sequentially connected to the filter 1 and the c...

Embodiment 2

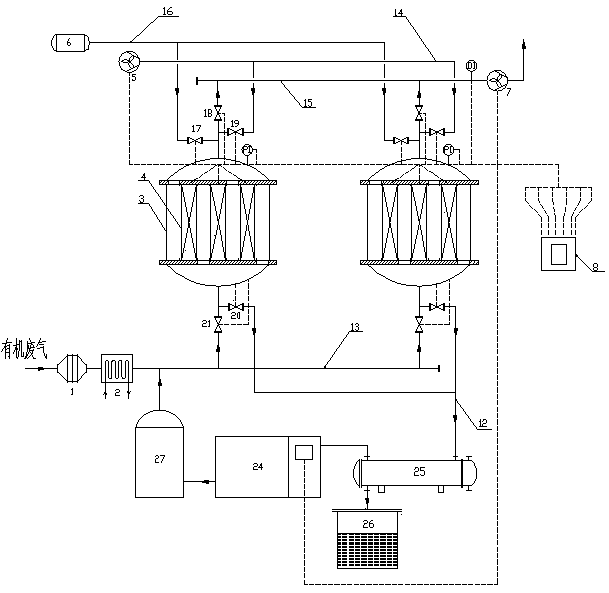

[0054] Example 2 (recovery and treatment of vacuum liquid ring)

[0055] The activated carbon adsorption and purification system and method using vacuum electrothermal regeneration in this embodiment are as follows: figure 2 As shown, the vacuum aftertreatment system of this embodiment includes a condenser A25, a liquid storage tank A26, a vacuum unit 24 and a gas-liquid separator 27, the air inlet of the condenser A25 communicates with the end of the desorption pipeline 12, and the condenser A25 The liquid outlet is connected with the liquid storage tank A26, the air outlet of the condenser A25 is connected with the air inlet of the vacuum unit 24, the air outlet of the vacuum unit 24 is connected with the air inlet of the gas-liquid separator 27, and the outlet of the gas-liquid separator 27 The gas port communicates with the adsorption pipeline 13, and the vacuum unit includes a liquid ring vacuum pump, a Roots vacuum pump, and a cooler. The working fluid of the liquid rin...

Embodiment 3

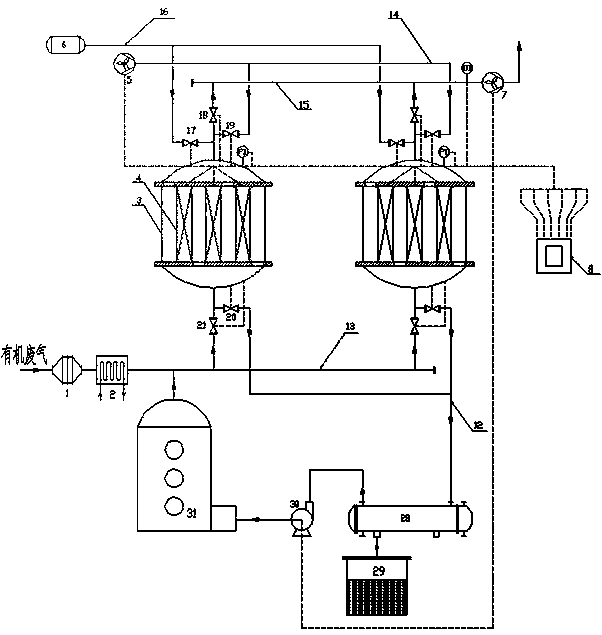

[0057] Embodiment 3 (vacuum absorption recovery treatment)

[0058] The activated carbon adsorption and purification system and method using vacuum electrothermal regeneration in this embodiment are as follows: image 3 As shown, the vacuum post-processing system of this embodiment includes a condenser B28, a liquid storage tank B29, a dry vacuum pump B30 and an absorption tower 31. The liquid outlet of the condenser B28 is connected to the liquid storage tank B29, and the gas outlet of the condenser B29 is It is connected with the air inlet of the dry vacuum pump B30, the air outlet of the dry vacuum pump B30 is connected with the air inlet of the absorption tower 31, the air inlet of the condenser B28 is communicated with the end of the desorption pipeline 12, and the air outlet of the absorption tower 31 is connected with the air inlet of the absorption tower 31. Adsorption pipeline 13 communicates.

[0059] The method for absorbing and recovering organic waste gas by usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com