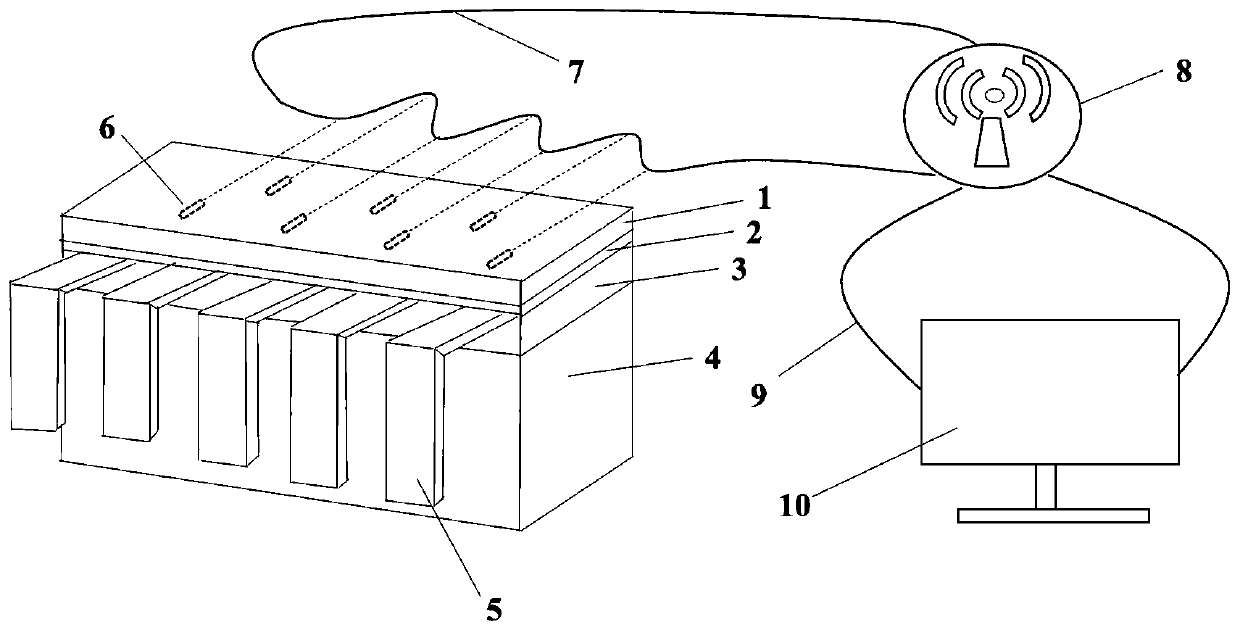

Active snow melting and deicing pavement structure and paving process thereof

A kind of pavement structure and active technology, which is applied to the coagulation pavement, roads, roads and other directions paved on site, can solve the problems of insufficient road compaction, performance degradation, maintenance and repair difficulties, etc., to reduce the temperature and slow down the rutting deformation. , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

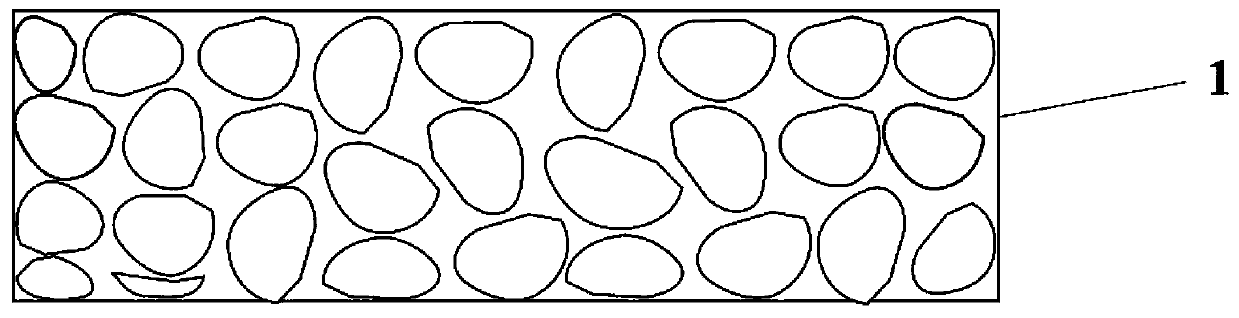

Embodiment 1

[0104] The thickness of the plastic base is 20cm, the thickness of the steel plate is 0.5cm, the bonding material of the bonding layer is polyurethane or epoxy resin, the heating cable is arranged under the steel plate in an S shape, and the distance between two adjacent cables is 10cm, and the heat-conducting metal is made of aluminum Or copper products, adopt 90° bending, one end is buried between two heating cables, one end is buried in the roadbed 100cm, the surface layer of large void asphalt mixture is 6cm thick, and the large void asphalt mixture adopts asphalt whose dynamic viscosity is greater than 60℃ 20 000 Pa·s high-viscosity modified asphalt, and the high-viscosity modified asphalt is mixed with graphite powder with a volume fraction of 8% of asphalt for secondary modification, and a pair of temperature sensors are laid every 2cm, buried at 2cm below the asphalt surface layer , the temperature collector is used to collect and store temperature sensor data, and the ...

Embodiment 2

[0108] The thickness of the plastic base is 25cm, the thickness of the steel plate is 1.0cm, the bonding material of the bonding layer is polyurethane or epoxy resin, the heating cable is arranged under the steel plate in an S shape, and the distance between two adjacent cables is 15cm, and the heat conducting metal is made of aluminum Or copper products, using 90° bending, one end is buried between two heating cables, and the other end is buried in the roadbed 200cm, the surface layer of large void asphalt mixture is 8cm thick, and the large void asphalt mixture adopts asphalt whose dynamic viscosity is greater than 60°C 20 000 Pa·s high-viscosity modified asphalt, and the high-viscosity modified asphalt is mixed with graphite powder with a volume fraction of 10% of the asphalt for secondary modification. A pair of temperature sensors are laid every 3 cm and buried 3 cm below the asphalt surface layer , the temperature collector is used to collect and store temperature sensor ...

Embodiment 3

[0112] The thickness of the plastic base is 22cm, the thickness of the steel plate is 0.5cm, the bonding material of the bonding layer is polyurethane or epoxy resin, the heating cable is arranged under the steel plate in an S shape, and the distance between two adjacent cables is 9cm, and the heat-conducting metal is made of aluminum Or copper products, adopt 90° bending, one end is buried between two heating cables, and the other end is buried in the roadbed 150cm, the surface layer of large void asphalt mixture is 6cm thick, and the large void asphalt mixture adopts asphalt whose dynamic viscosity is greater than 60°C 20 000 Pa·s high-viscosity modified asphalt, and the high-viscosity modified asphalt is mixed with graphite powder with a volume fraction of 8% of the asphalt for secondary modification, and a pair of temperature sensors are laid every 3 cm, buried 3 cm below the asphalt surface layer , the temperature collector is used to collect and store temperature sensor d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com