Pt/C-N composite electrocatalytic material with efficient hydrogen evolution performance and preparation method thereof

An electrocatalytic material, C-N technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low catalytic activity of catalysts, difficult to achieve large-scale utilization, and high preparation costs, and achieve high efficiency. The effect of hydrogen evolution performance, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] raw material:

[0026] Biochar material (white radish) is a commercially available raw material

[0027] Chloroplatinic acid hexahydrate is the raw material of Aladdin's official website

[0028] Cut the white radish into slices of 1*1*2cm, and soak it in 0.08mol / L chloroplatinic acid precursor solution for 6 hours.

[0029] After impregnation, the sample was freeze-dried at a freezing temperature of -60°C, a vacuum of 1 Pa, a freezing time of 1 day, and a drying time of 2 days to obtain a biochar precursor capable of maintaining the cell structure of the biochar material.

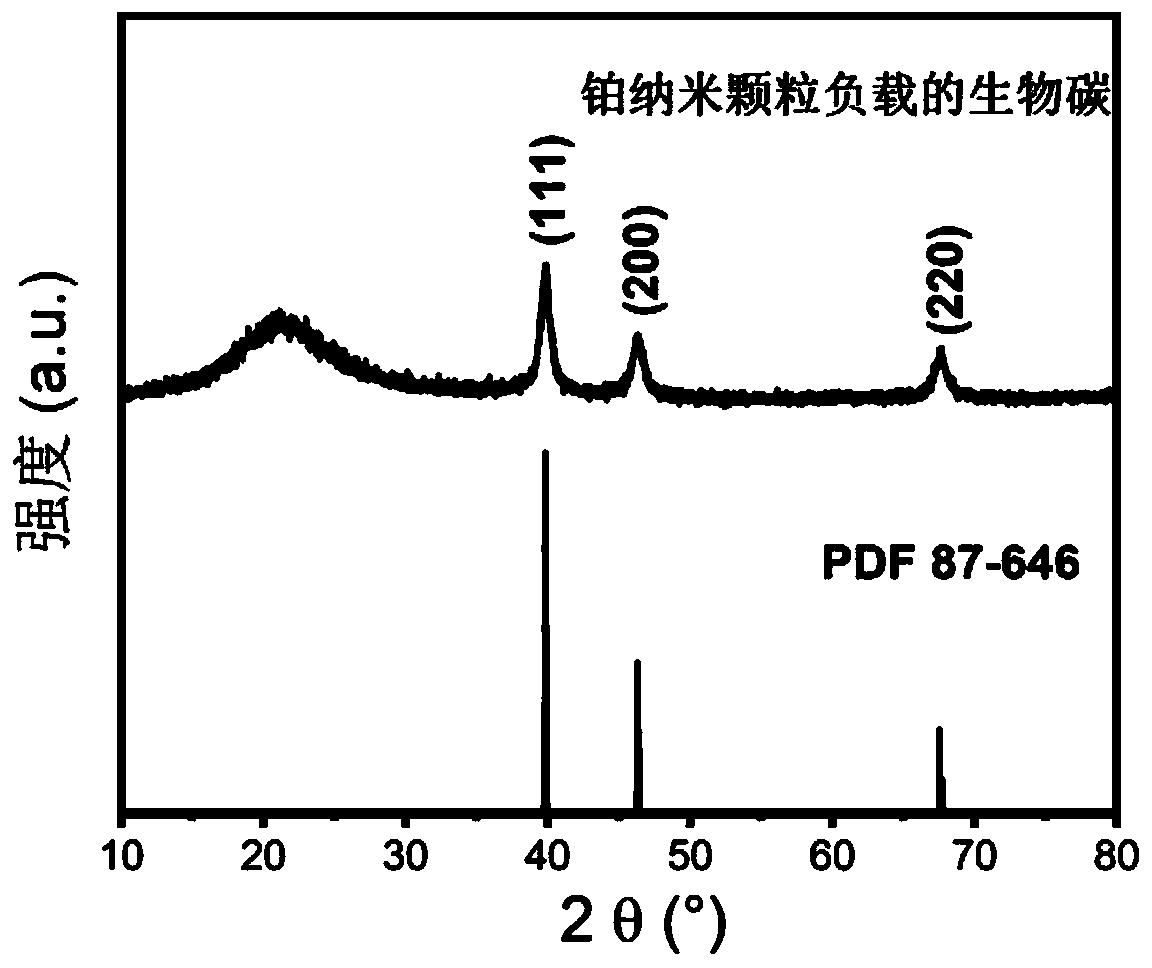

[0030] The biochar precursor was carbonized at a carbonization temperature of 600 °C, the heating rate was 2 °C / min, the holding time was 2 hours, and the protective atmosphere was Ar gas to obtain a Pt / C-N composite electrocatalytic material.

[0031] Using the bioporous carbon material loaded with Pt metal nanoparticles as the catalyst, its electrochemical hydrogen evolution performance was test...

Embodiment 2

[0033] raw material:

[0034] Biochar material (white radish) is a commercially available raw material

[0035] Chloroplatinic acid hexahydrate is the raw material of Aladdin's official website

[0036] Cut the white radish into slices of 1*1*2cm, and soak it in 0.04mol / L chloroplatinic acid precursor solution for 6 hours.

[0037] After impregnation, the sample was freeze-dried at a freezing temperature of -60°C, a vacuum of 1 Pa, a freezing time of 1 day, and a drying time of 2 days to obtain a biochar precursor capable of maintaining the cell structure of the biochar material.

[0038] The biochar precursor was carbonized at a carbonization temperature of 600 °C, the heating rate was 2 °C / min, the holding time was 2 hours, and the protective atmosphere was Ar gas to obtain a Pt / C-N composite electrocatalytic material.

Embodiment 3

[0040] raw material:

[0041] Biochar material (white radish) is a commercially available raw material

[0042] Chloroplatinic acid hexahydrate is the raw material of Aladdin's official website

[0043] Cut the white radish into slices of 1*1*2cm, and soak it in 0.12mol / L chloroplatinic acid precursor solution for 6 hours.

[0044] After impregnation, the sample was freeze-dried at a freezing temperature of -60°C, a vacuum of 1 Pa, a freezing time of 1 day, and a drying time of 2 days to obtain a biochar precursor capable of maintaining the cell structure of the biochar material.

[0045] The biochar precursor was carbonized at a carbonization temperature of 600 °C, the heating rate was 2 °C / min, the holding time was 2 hours, and the protective atmosphere was Ar gas to obtain a Pt / C-N composite electrocatalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com