Manufacturing method of rigid-flexible printed circuit board with multi-step buried blind holes

A technology of rigid-flex board and manufacturing method, which is applied in multilayer circuit manufacturing, printed circuit manufacturing, cleaning/polishing of conductive patterns, etc. board etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

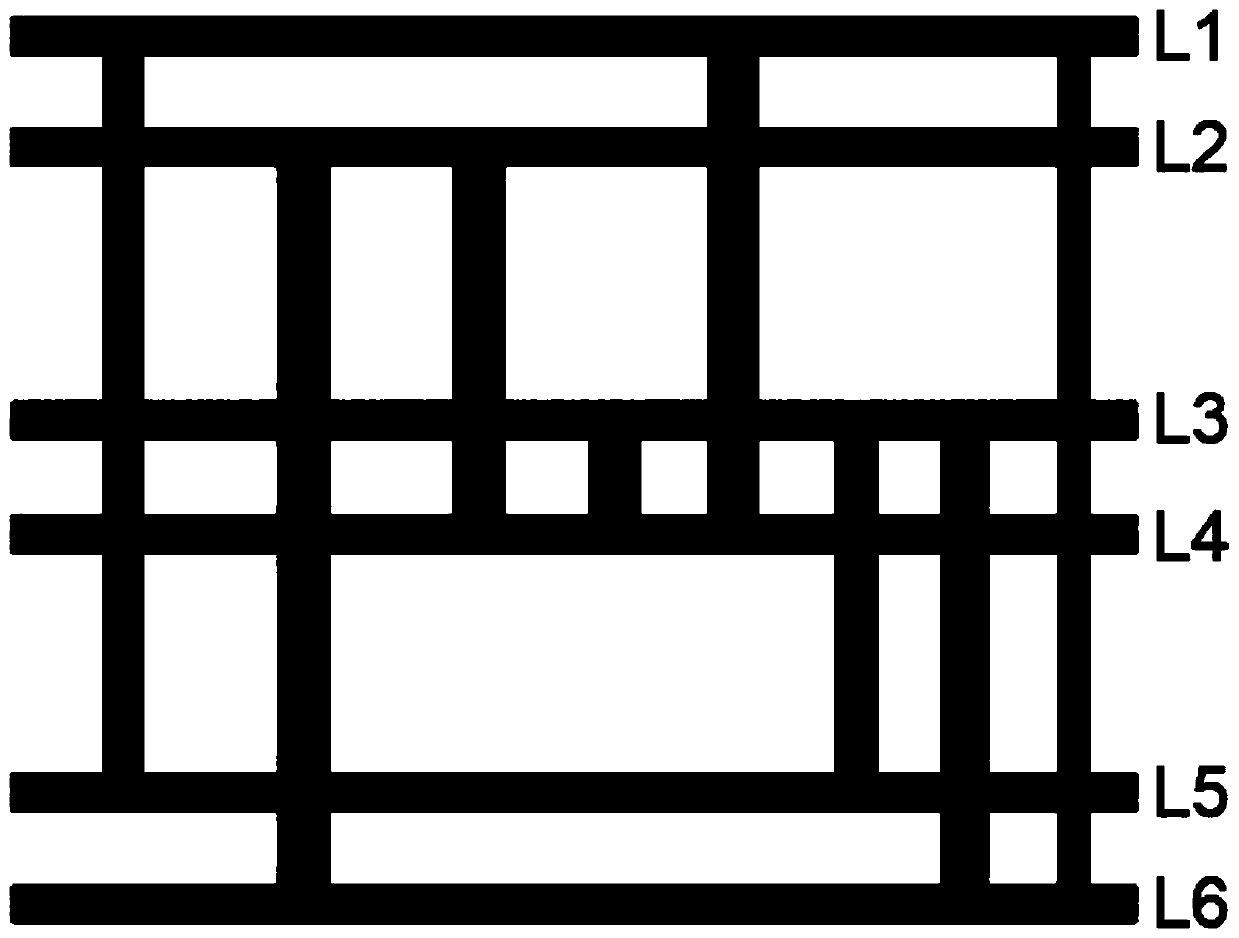

[0023] Such as figure 1 As shown, a three-stage six-layer rigid-flex board has a variety of blind holes, which can greatly enrich the functions that the rigid-flex board can achieve under a certain volume.

[0024] The manufacturing method of the above-mentioned rigid-flex board includes the manufacture of the inner layer copper-flexible board, the manufacture of the middle layer copper-flexible board and the manufacture of the outer layer copper-flexible board;

[0025] The production of the inner copper soft board includes: pretreatment, copper sinking, copper plating, post-treatment, pasting CVL, pressing, baking, and to be laminated;

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com