Beam dyeing penetration detection device

A technique of penetrant detection and warp beam dyeing, which is applied in the field of warp beam dyeing penetrant detection devices, can solve the problems of poor beam burst rate control and low efficiency, and achieve the effects of easy promotion, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

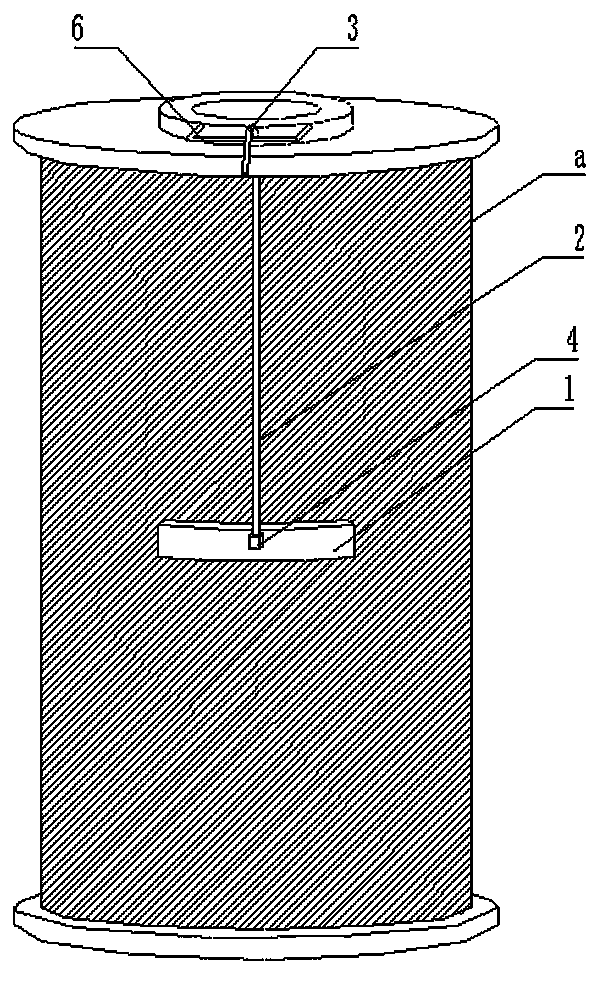

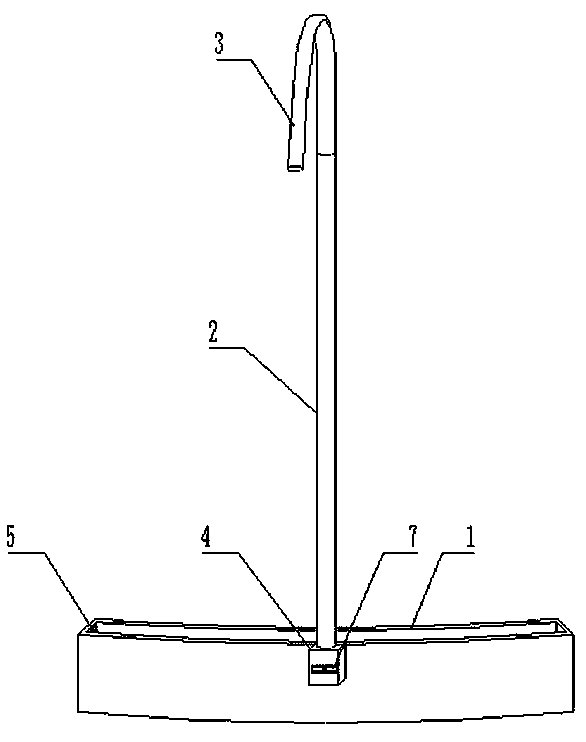

[0019] Such as figure 1 , figure 2 As shown, a warp beam dyeing penetration detection device of the present invention, the warp beam dyeing penetration detection device includes an arc-shaped groove 1, a connecting seat 4 is arranged in the center on the outer side of the arc-shaped groove 1, and a connecting seat 4 is arranged on the upper part of the connecting seat 4. Rod 2, the top of the connecting rod 2 is provided with a "u" handle 3; the arc groove 1 is provided with a scale 5; the length of the connecting rod 2 can be adjusted.

[0020] A level 7 is arranged outside the connecting seat 4 .

[0021] The inner side of the arc-shaped groove 1 is made of soft material.

[0022] The "u"-shaped handle 3, the connecting seat 4 and the connecting rod 2 are respectively connected by threads.

[0023] Scale scales 5 are arranged around the inside of the arc-shaped groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com