Air energy heat pump evaporator structure

An air-energy heat pump and evaporator technology, which is applied in the direction of evaporator/condenser, heat pump, heat exchange equipment, etc. The effect of absorption efficiency and heat exchange efficiency, reducing energy consumption, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0026] Embodiments of the invention

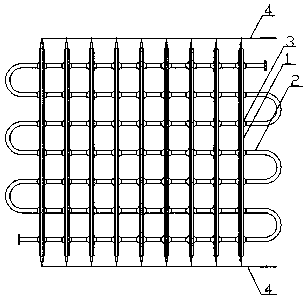

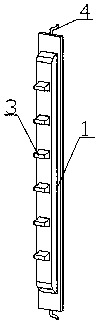

[0027] An air energy heat pump evaporator structure, as attached Figure 1-5 As shown, it includes a number of heat-absorbing fins 1 arranged side by side and a refrigerant conduit 2 interspersed on the heat-absorbing fins 1 in an S shape; each of the heat-absorbing fins 1 is connected by two single-layer metal sheets. into, and is hollow.

[0028] The single-layer heat-absorbing fins are pressed through the mold, and the middle part is pressed out with a pit. The two single-layer heat-absorbing fins are arranged opposite each other, with the pits facing outward. After welding the surroundings of the joints, a hollow heat-absorbing fin can be formed. Fin 1, the heat-absorbing fin 1 is provided with a plurality of through holes for the refrigerant conduit 2 to pass through. During operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com