High-toughness, durable and anti-skid steel bridge deck pavement structure and construction method thereof

A steel bridge deck and pavement technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of easy bulging and cracking, low early anti-skid performance, and high requirements for construction equipment, and achieve reliable high temperature stability. The effect of low rate and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

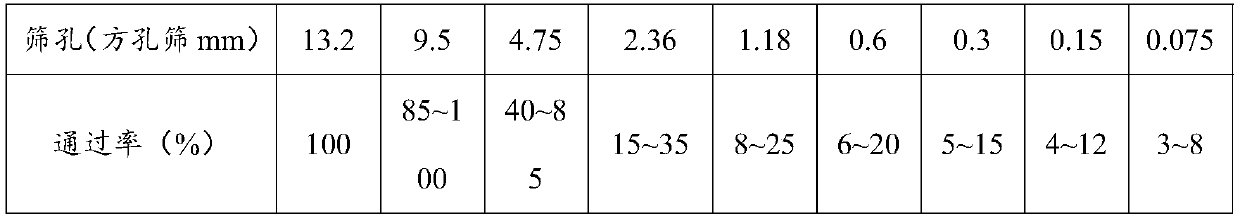

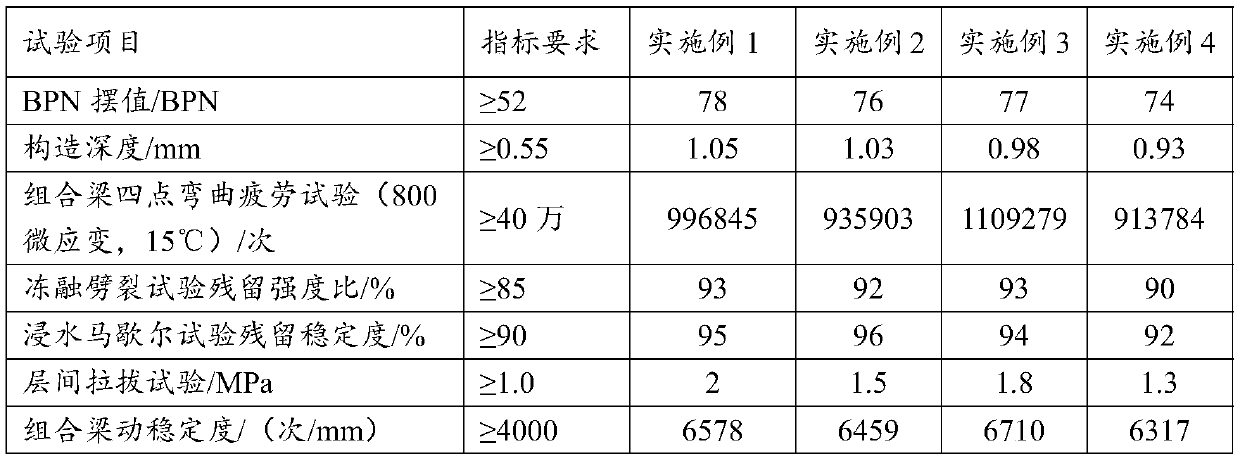

[0045] The present embodiment provides a high-toughness, durable, anti-skid steel deck pavement structure, comprising steel deck steel plates, the surface of the steel deck steel plates is successively laid with a bonding bottom layer, a buffer layer, an adhesive Layer and wear layer, buffer layer and wear layer are high-toughness modified asphalt concrete composed of aggregate, filler and asphalt binder, the mass ratio of aggregate, filler and asphalt binder in the buffer layer is 100:5: 7.6, the mass ratio of aggregate, filler and asphalt binder in the wear layer is 100:6:7.8.

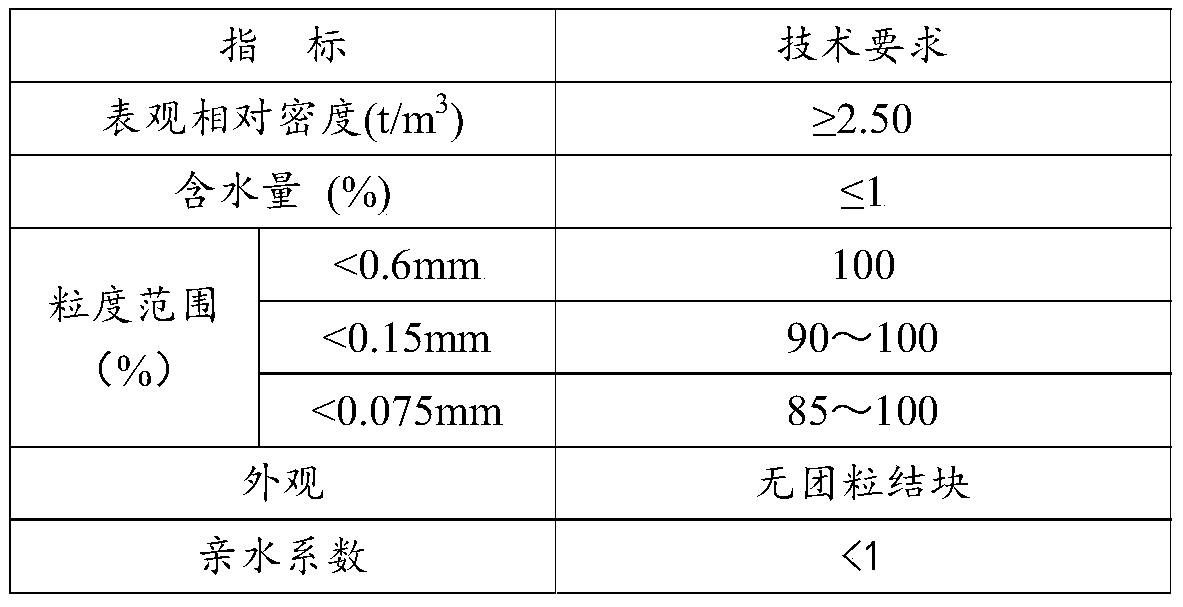

[0046] Among them, the adhesive base layer and the adhesive layer are all made of epoxy resin adhesive layer oil produced by Kindai Kasei Co., Ltd., the model is KD-HYP, and the main agent and curing agent are mixed at a weight ratio of 1:1; the aggregate is made of dark green Limestone slag is used as filler; asphalt binder is high-viscosity and high-elasticity modified asphalt produced by Huayun To...

Embodiment 2

[0059] The present embodiment provides a high-toughness, durable, anti-skid steel deck pavement structure, comprising steel deck steel plates, the surface of the steel deck steel plates is successively laid with a bonding bottom layer, a buffer layer, an adhesive Layer and wear layer, buffer layer and wear layer are high-toughness modified asphalt concrete composed of aggregate, filler and asphalt binder, the mass ratio of aggregate, filler and asphalt binder in the buffer layer is 100:5: 7.8, the mass ratio of aggregate, filler and asphalt binder in the wearing course is 100:6:8.0.

[0060] Among them, the adhesive bottom layer adopts the epoxy resin adhesive layer oil produced by Japan Modern Chemical Co., Ltd., the model is KD-HYP, and the main agent and the curing agent are mixed at a weight ratio of 1:1; High-elastic modified emulsified asphalt; the aggregate is made of diabase, and the filler is made of limestone powder; the asphalt binder is made of high-viscosity and h...

Embodiment 3

[0073] The present embodiment provides a high-toughness, durable, anti-skid steel deck pavement structure, comprising steel deck steel plates, the surface of the steel deck steel plates is successively laid with a bonding bottom layer, a buffer layer, an adhesive Layer and wear layer, buffer layer and wear layer are high-toughness modified asphalt concrete composed of aggregate, filler and asphalt binder, the mass ratio of aggregate, filler and asphalt binder in the buffer layer is 100:5: 8. The mass ratio of aggregate, filler and asphalt binder in the wear layer is 100:6:7.6.

[0074]Among them, the adhesive base layer and the adhesive layer are all made of epoxy resin adhesive layer oil produced by Kindai Kasei Co., Ltd., the model is KD-HYP, and the main agent and curing agent are mixed at a weight ratio of 1:1; the aggregate is made of dark green Limestone slag is used as filler; asphalt binder is high-viscosity and high-elasticity modified asphalt produced by Huayun Tongd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com