Buckling and placing tool for steel ball heat treatment applied to bearing assembly

A technology of steel balls and bearings, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problem of lack of heat treatment process tooling for steel balls, achieve good heat treatment effects, simple overall structure of the device, and increase heat treatment speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

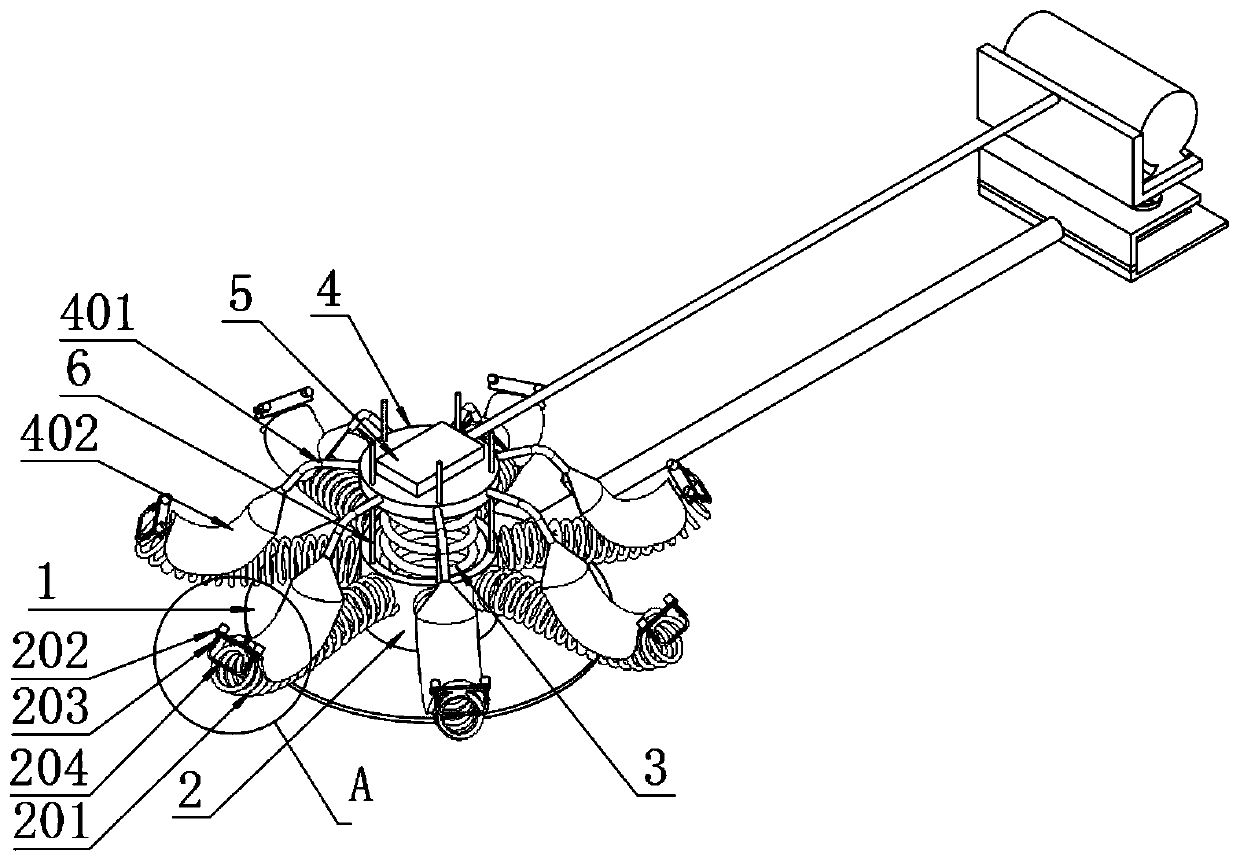

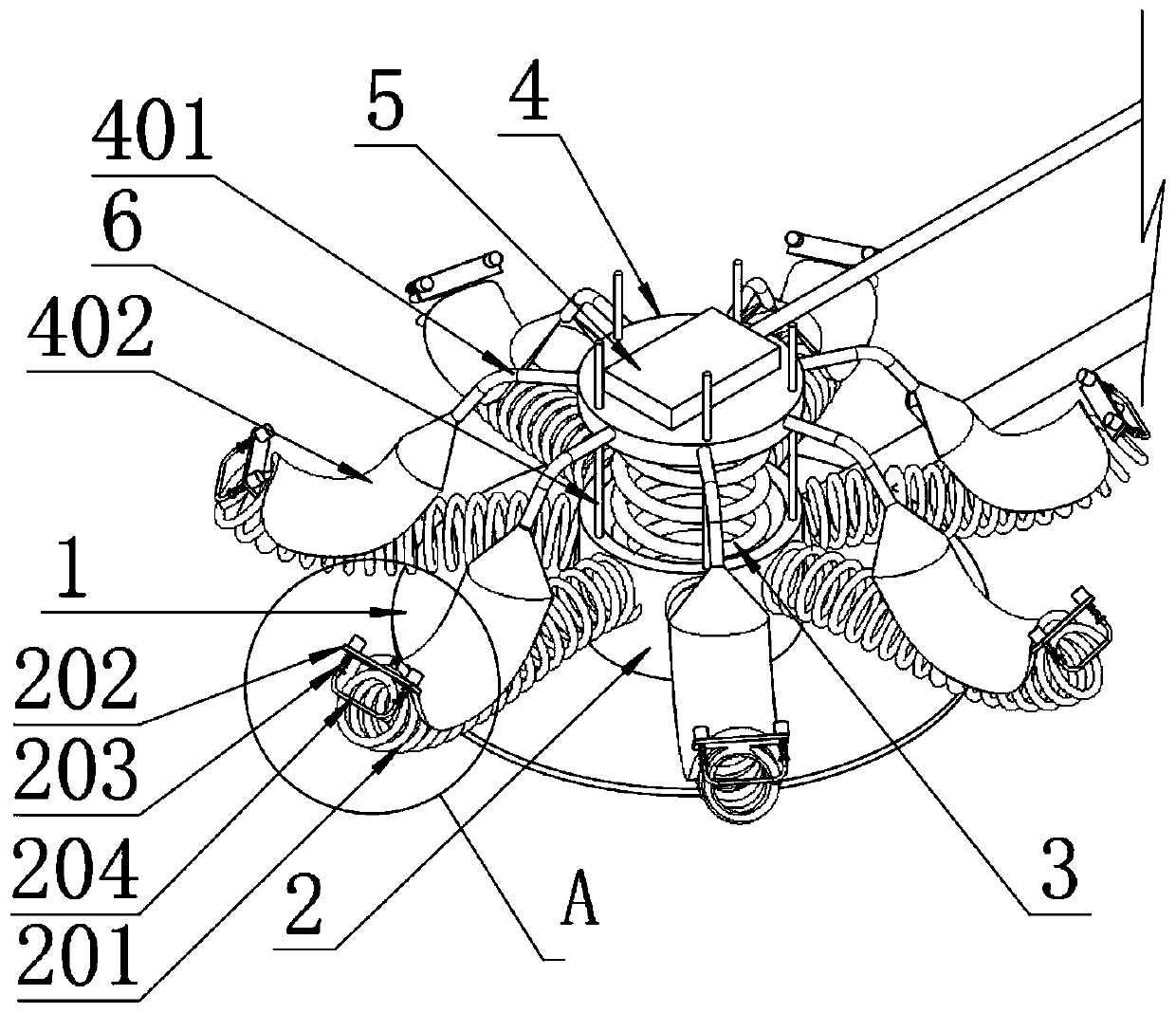

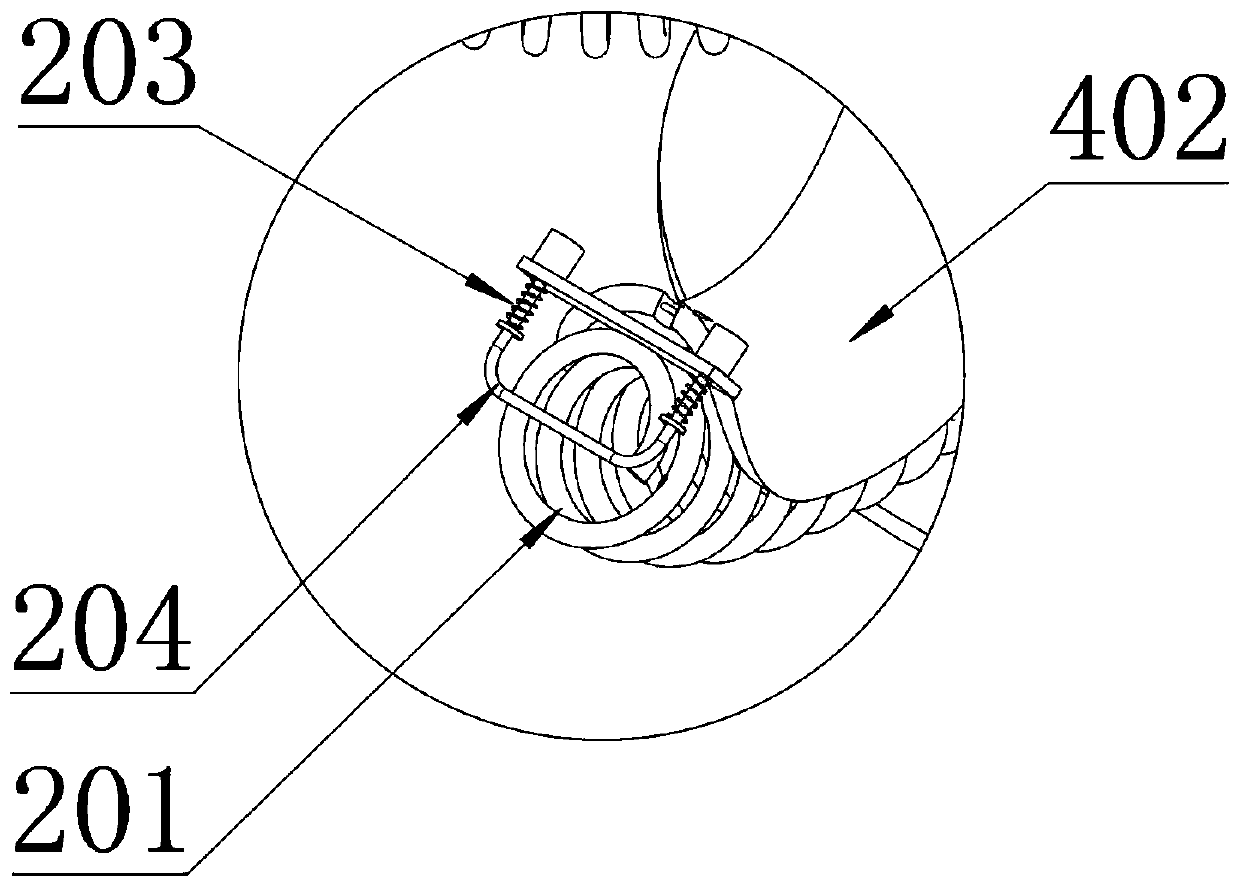

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The present invention provides a buckle-and-release tool for steel ball heat treatment for bearing assembly, including a base plate 1 and a pressure seat 5; the base plate 1 is a circular plate structure, and a large circular cavity is welded in the middle of it in a vertical manner The column 2 of the cylinder structure; a large spring 3 is also welded in the cylindrical cavity of the column 2 in a vertical manner, and a drop plate 4 is welded on the top of the large spring 3; the pressure seat 5 is a rectangular shell The body part is welded on the top surface of the drop plate 4 in an inverted manner, and a top extension rod 9 is welded on the outer end of the pressure seat 5; A threaded sleeve 7, and this threaded sleeve 7 is threaded with a bottom extension rod 8 extending outwards; the top extension rod 9 and the bottom extension rod 8 are arranged in parallel up and down positions; The end is welded with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com