Nitridation quenching process based on vacuum carburization machine

A vacuum carburizing and process technology, used in quenching devices, manufacturing tools, heat treatment equipment, etc., can solve the problems of wasting plant space and wasting the cost of purchasing equipment, and achieve cost savings and good heat treatment effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be further described in detail below.

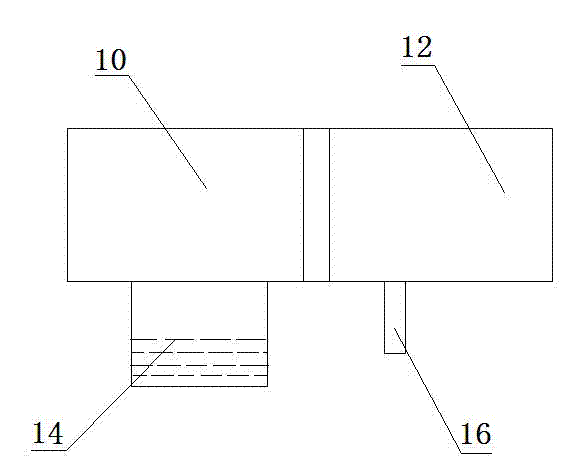

[0014] like figure 1 As shown, the vacuum carburizing machine includes the following structures: an antechamber 10, a heating chamber 12, an oil pool 14, and it also includes a conveyor belt for transporting workpieces to be processed between the antechamber 10, the heating chamber 12, and the oil pool 14 ( not shown), the heating chamber 12 is connected to the ammonia gas pipe 16 .

[0015] And a kind of nitriding quenching process based on vacuum carburizing machine of the present invention is to finish in vacuum carburizing machine, and it comprises the following steps:

[0016] 1) Preheating, the workpiece is sent into the heating chamber 12 of the vacuum carburizing machine through the front chamber 10 and heated to 500-700°C, and the best temperature is about 600°C±3°C;

[0017] 2) Ammonia gas is charged, and ammonia gas is charged into the heating chamber 12 of the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com