Cold-heat converter for metal surface heat treatment

A metal surface and converter technology, applied in heat treatment equipment, electrodes, quenching devices, etc., can solve the problems of large volume, complex overall structure of the device, and complicated structure of the heat treatment system, so as to simplify the pipeline structure, improve the electrolysis speed and effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

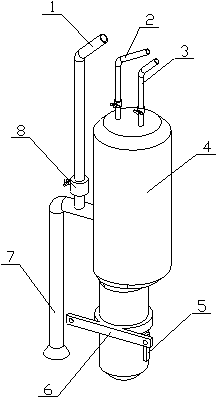

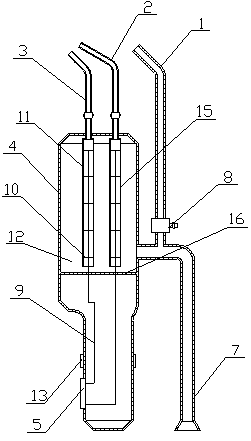

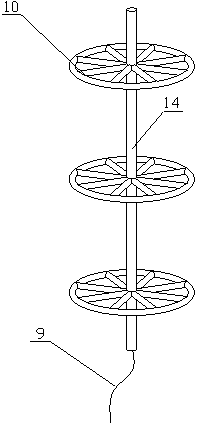

[0015] A cold-heat converter for metal surface heat treatment of the present invention is realized in the following way: a cold-heat converter for metal surface heat treatment of the present invention consists of a water outlet pipe (1), an oxygen pipe (2), a hydrogen pipe (3), and a protective shell (4), power supply (5), fixed plate (6), water inlet pipe (7), control valve (8), wire (9), mesh electrode (10), hydrogen electrolysis tube (11), reaction cell (12 ), fixed ring (13), conduit (14), oxygen electrolysis tube (15) and water baffle (16), the protective shell (4) is built with a water baffle (16), and the water baffle (16) will The protective shell (4) is divided into a reaction pool (12) and a wiring cavity. The reaction pool (12) is located above the wiring cavity. A fixing ring (13) is fixedly sleeved on the outer surface of the wiring cavity. The fixing plate (6) It is fixedly connected with the outer surface of the fixing ring (13), the power supply (5) is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com