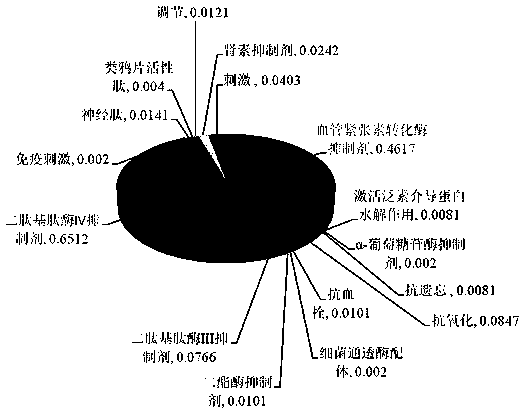

ACE (angiotensin converting enzyme) inhibition peptide with nutrition repairing and cell function activation and preparation method

A technology for inhibiting peptides and cells, applied in the field of small molecule peptides, can solve problems such as side effects and weak damage repair effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

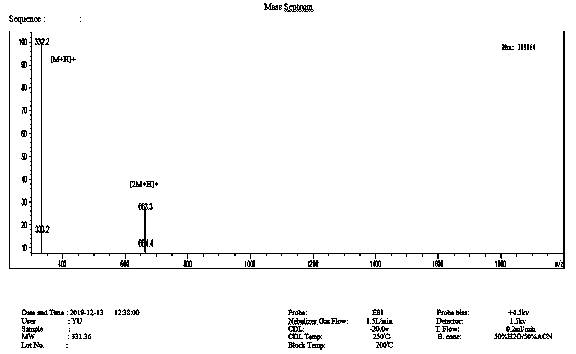

Image

Examples

Embodiment 1

[0036] Weigh 200g black beans: 200g black peanuts: 100g black sesame: 100g black rice: 100g black oats: 80g wolfberry: 100g black mulberries: 30g blackberries: 80g brown sugar;

[0037] A. The fermenter is fully sterilized with alcohol and sterilized by boiling water;

[0038] B. Clean the above-mentioned materials with water, dry them to remove water and use a wall breaking machine to break the walls and crush them, and then pour the materials into the fermentation tank;

[0039] C. Add boiling water to the fermenter, material: water volume ratio = 1: 4, stir evenly;

[0040] D. When the temperature in the fermenter drops to about room temperature, add fermented bacteria powder in the fermenter, yeast: lactic acid bacteria=1:1, seal for 7 days and ferment;

[0041] E. Hydrolysis: put the fermentation broth in a mixed enzymatic fermentation tank, raise the temperature to 53°C, add 0.1% W of cellulase, the reaction temperature is between 45-65°C, the pH is controlled around 6....

Embodiment 2

[0047] Weigh 300g black beans: 300g black peanuts: 150g black sesame: 150g black rice: 150g black oats: 125g wolfberry: 150g black mulberries: 80g blackberries: 125g brown sugar;

[0048] A. The fermenter is fully sterilized with alcohol and sterilized by boiling water;

[0049] B. Clean the above-mentioned materials with water, dry them to remove water and use a wall breaking machine to break the walls and crush them, and then pour the materials into the fermentation tank;

[0050] C. Add boiling water to the fermenter, material: water volume ratio = 1: 4, stir evenly;

[0051] D. When the temperature in the fermenter drops to about room temperature, add fermented bacteria powder in the fermenter, yeast: lactic acid bacteria=1:1, seal for 7 days and ferment;

[0052] E. Hydrolysis: put the fermentation broth in a mixed enzymatic fermentation tank, raise the temperature to 53°C, add 0.1% W of cellulase, the reaction temperature is between 45-65°C, the pH is controlled around ...

Embodiment 3

[0058] Weigh 250g of black beans according to the ratio of parts by weight: 250g of black peanuts: 125g of black sesame: 125g of black rice: 125g of black oats: 100g of wolfberry: 125g of black mulberries: 50g of blackberries: 100g of brown sugar;

[0059] A. The fermenter is fully sterilized with alcohol and sterilized by boiling water;

[0060] B. Clean the above-mentioned materials with water, dry them to remove water and use a wall breaking machine to break the walls and crush them, and then pour the materials into the fermentation tank;

[0061] C. Add boiling water to the fermenter, material: water volume ratio = 1: 4, stir evenly;

[0062] D. When the temperature in the fermenter drops to about room temperature, add fermented bacteria powder in the fermenter, yeast: lactic acid bacteria=1:1, seal for 7 days and ferment;

[0063] E. Hydrolysis: put the fermentation broth in a mixed enzymatic fermentation tank, raise the temperature to 53°C, add 0.1% W of cellulase, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com