A temperature-resistant and salt-resistant gemini amphoteric surfactant and its preparation method and application

A surfactant, temperature and salt resistance technology, applied in the preparation of sulfonic acid, the preparation of carboxylic acid amides, chemical instruments and methods, etc., can solve the problems of complex fracturing fluid system composition, inconvenient on-site fluid preparation, poor temperature resistance, etc. , to achieve the effect of excellent suspended sand performance, low cost and easy reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of a temperature-resistant and salt-resistant gemini amphoteric surfactant, comprising the following steps:

[0045] (1) Dissolve 100mmol of oleic amidopropyldimethylamine in 250mL of isopropanol, then add 120mmol of hydrochloric acid, stir at room temperature for 10min, then add 150mmol of epichlorohydrin dropwise, and react at 50°C for 3h , evaporated to remove solvent and excess with epichlorohydrin to obtain intermediate one;

[0046] (2) Add 120mmol of taurine, 250mL of distilled water and 200mL of isopropanol to intermediate one obtained in step (1), then add 130mmol of sodium bicarbonate, reflux at a temperature of 50°C for 10h, then add 300mL of acetone, and Standing at ℃ for 3h, intermediate 2 was obtained;

[0047] (3) Add 65mmol of 1,4-dibromobutane and 200mL of ethanol to intermediate 2 obtained in step (2), then add 130mmol of sodium bicarbonate, react at 60°C for 12h, then add 300mL of acetone, 3°C Recrystallize at high temperature f...

Embodiment 2

[0050] A preparation method of a temperature-resistant and salt-resistant gemini amphoteric surfactant, comprising the following steps:

[0051] (1) Dissolve 100mmol of erucamidopropyldimethylamine in 250mL of ethanol, then add 120mmol of hydrochloric acid, stir at room temperature for 10min, then add 150mmol of epichlorohydrin dropwise, react at 60°C for 2h, evaporate Remove the solvent and excess with epichlorohydrin to obtain intermediate one;

[0052] (2) Add 120mmol of taurine, 300mL of distilled water and 200mL of isopropanol to intermediate one obtained in step (1), then add 130mmol of sodium bicarbonate, reflux at a temperature of 50°C for 8h, then add 300mL of acetone, and Standing at ℃ for 3h, intermediate 2 was obtained;

[0053] (3) Add 70mmol of dibromoethane and 200mL of ethanol to intermediate 2 obtained in step (2), then add 130mmol of sodium bicarbonate, react at 50°C for 12h, then add 300mL of acetone, and recrystallize at 3°C After 4 hours, after removing ...

Embodiment 3

[0056] A preparation method of a temperature-resistant and salt-resistant gemini amphoteric surfactant, comprising the following steps:

[0057] (1) Dissolve 100mmol of erucamidopropyldimethylamine in 250mL of ethanol, then add 120mmol of hydrochloric acid, stir at room temperature for 10min, then add 150mmol of epichlorohydrin dropwise, react at 60°C for 2h, evaporate Remove the solvent and excess with epichlorohydrin to obtain intermediate one;

[0058] (2) Add 120mmol of taurine, 300mL of distilled water and 200mL of ethanol to intermediate one obtained in step (1), then add 130mmol of sodium bicarbonate, reflux at 50°C for 9h, then add 300mL of acetone, Stand still for 3h to obtain intermediate 2;

[0059] (3) Add 70mmol of dibromopentane and 200mL of ethanol to intermediate 2 obtained in step (2), then add 120mmol of sodium bicarbonate, react at 50°C for 11h, then add 300mL of acetone, and recrystallize at 3°C After 4 hours, after removing the solvent by evaporation, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

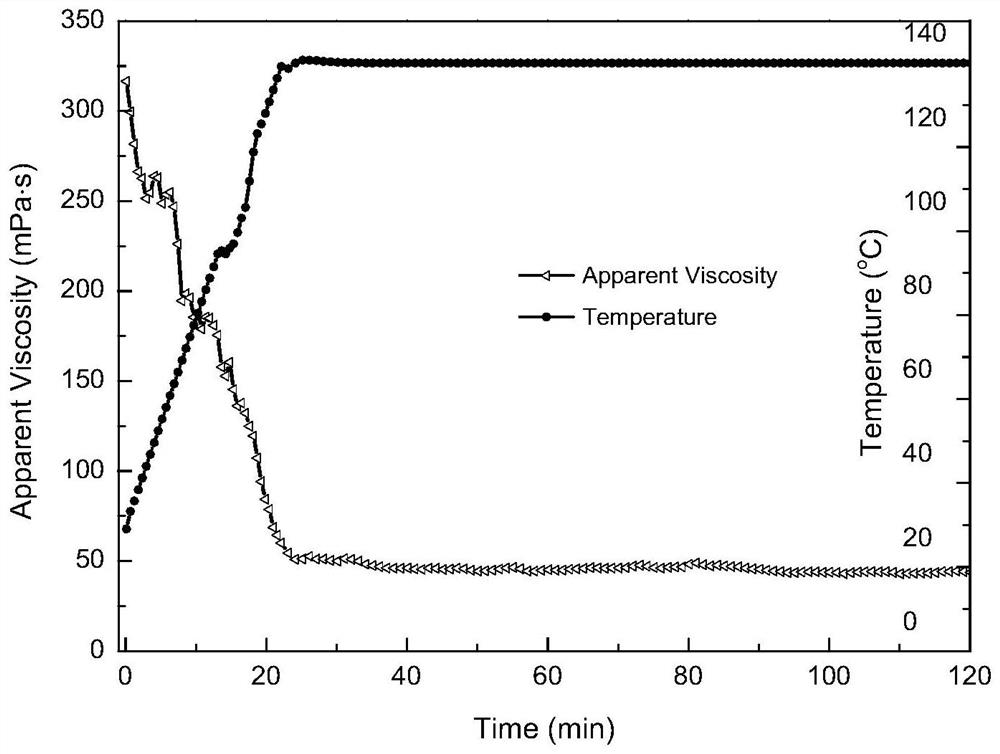

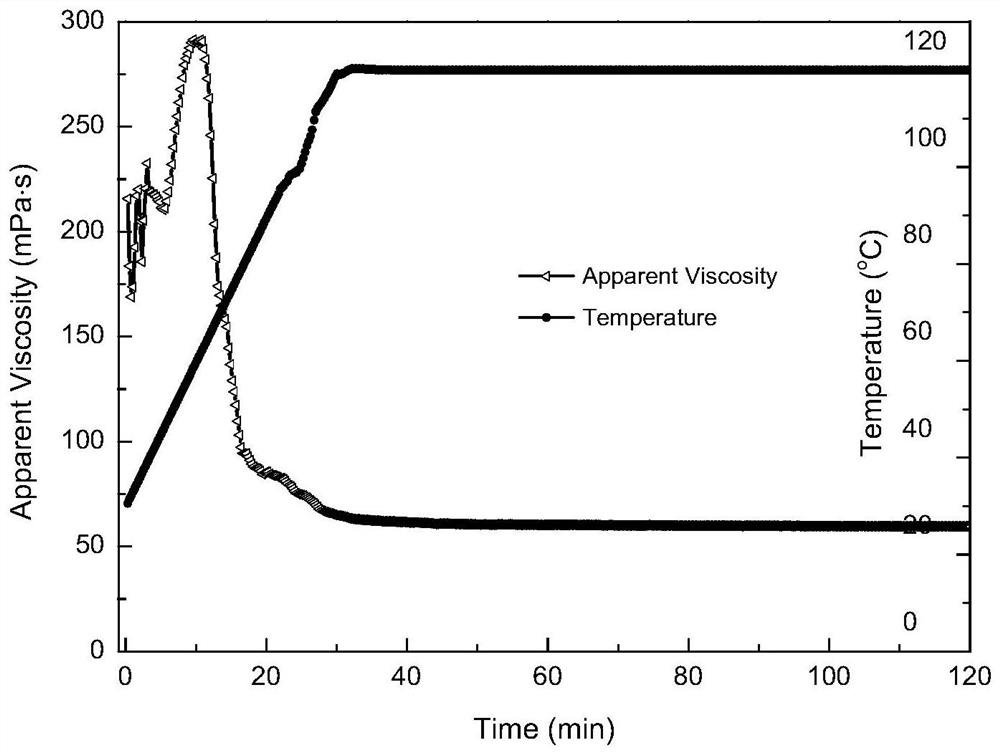

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com