Air desulfurization and dust reduction equipment for underground engineering construction

An underground engineering and air technology, applied in the direction of external electrostatic separator, power supply technology, electrostatic effect separation, etc., can solve the problems of normal operation of construction machinery, external environmental pollution, efficiency reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

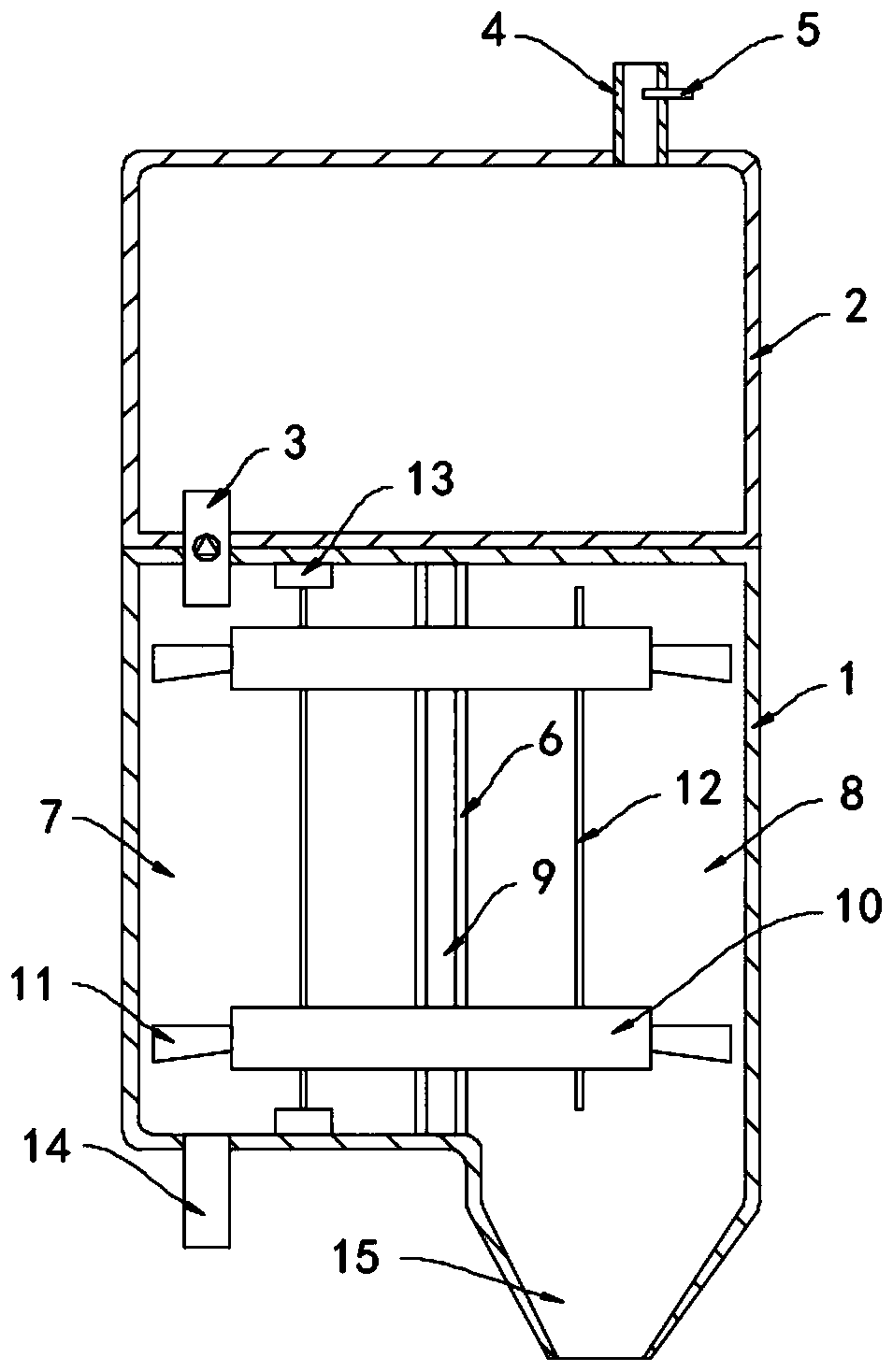

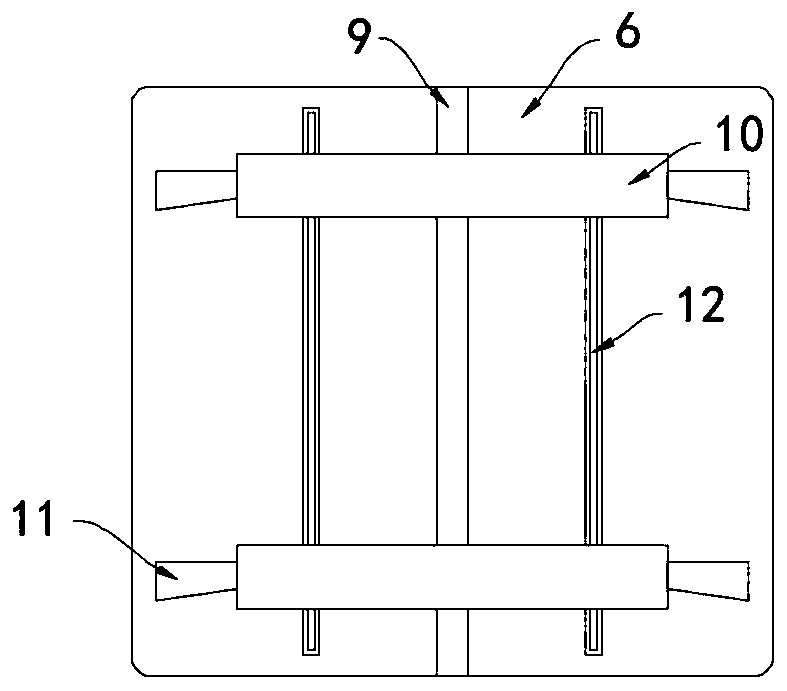

[0021] Such as Figure 1-2 As shown, an air desulfurization and dust reduction equipment for underground engineering construction includes an air intake box 1 and a desulfurization box 2 fixedly connected to the upper end of the air intake box 1, and the air intake box 1 is fixedly communicated with the desulfurization box 2 through a one-way communication pipe 3, The one-way communication pipe 3 only allows the air in the air intake box 1 to enter the desulfurization box 2, and the upper end of the desulfurization box 2 is fixedly connected with an exhaust pipe 4, and a thermoelectric power generation chip 5 is installed on the side wall of the exhaust pipe 4 to further The air box 1 is fixedly connected with a vertical partition 6, and the partition 6 divides the air intake box 1 into an electrostatic chamber 7 and a dust removal chamber 8, wherein the bottom of the electrostatic chamber 7 is fixedly connected with an air intake pipe 14, and the dust removal chamber 8 The lo...

Embodiment 2

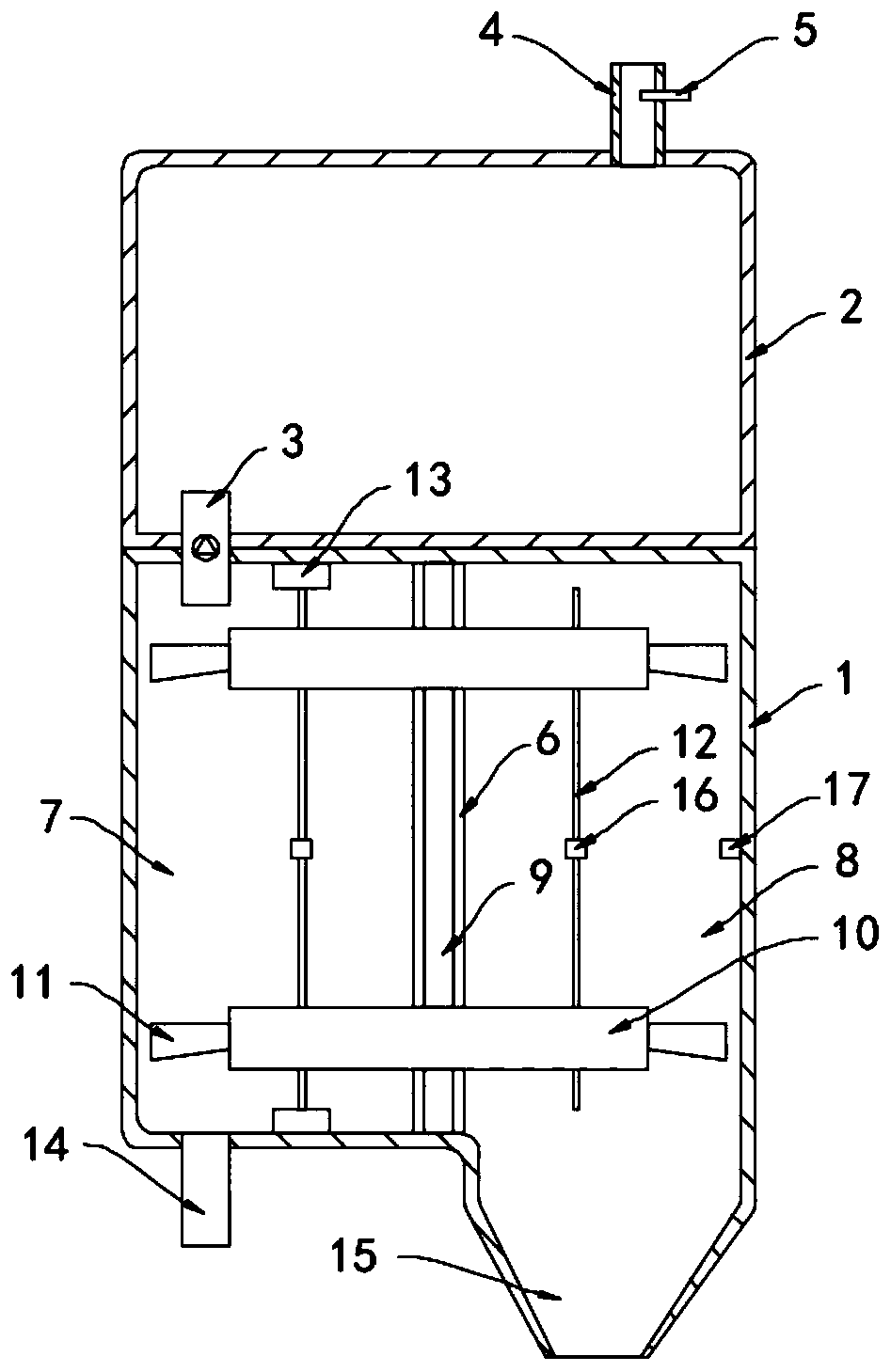

[0027] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is: the corona wire 12 is fixedly sleeved with a permanent magnet ring 16, and the side wall of the dust removal chamber 8 is fixedly connected to a horizontally arranged bar magnet 17, and the bar magnet The two ends magnetic poles of 17 are opposite.

[0028] In this embodiment, when the turntable 10 drives the corona wire 12 to rotate, the permanent magnetic ring 16 on the corona wire 12 is close to the two ends of the bar magnet 17 in turn, and under the action of the magnetic force, the bar magnet 17 is opposite to the corona. The permanent magnet ring 16 on the wire 12 produces periodically changing attractive and repulsive forces, which cause the corona wire 12 to vibrate slightly, which is beneficial to the capture and adsorption of the dust in the air by the corona wire 12 passing through the current, and at the same time, the corona wire 12 can capture and absorb dust in the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com