Bone dissociation device

A disconnection and sliding installation technology, applied in the field of medical devices, can solve the problems of unguaranteed safety, bone splitting at the disconnection site, uncertain shape of the bone fracture end, etc., to avoid repeated injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

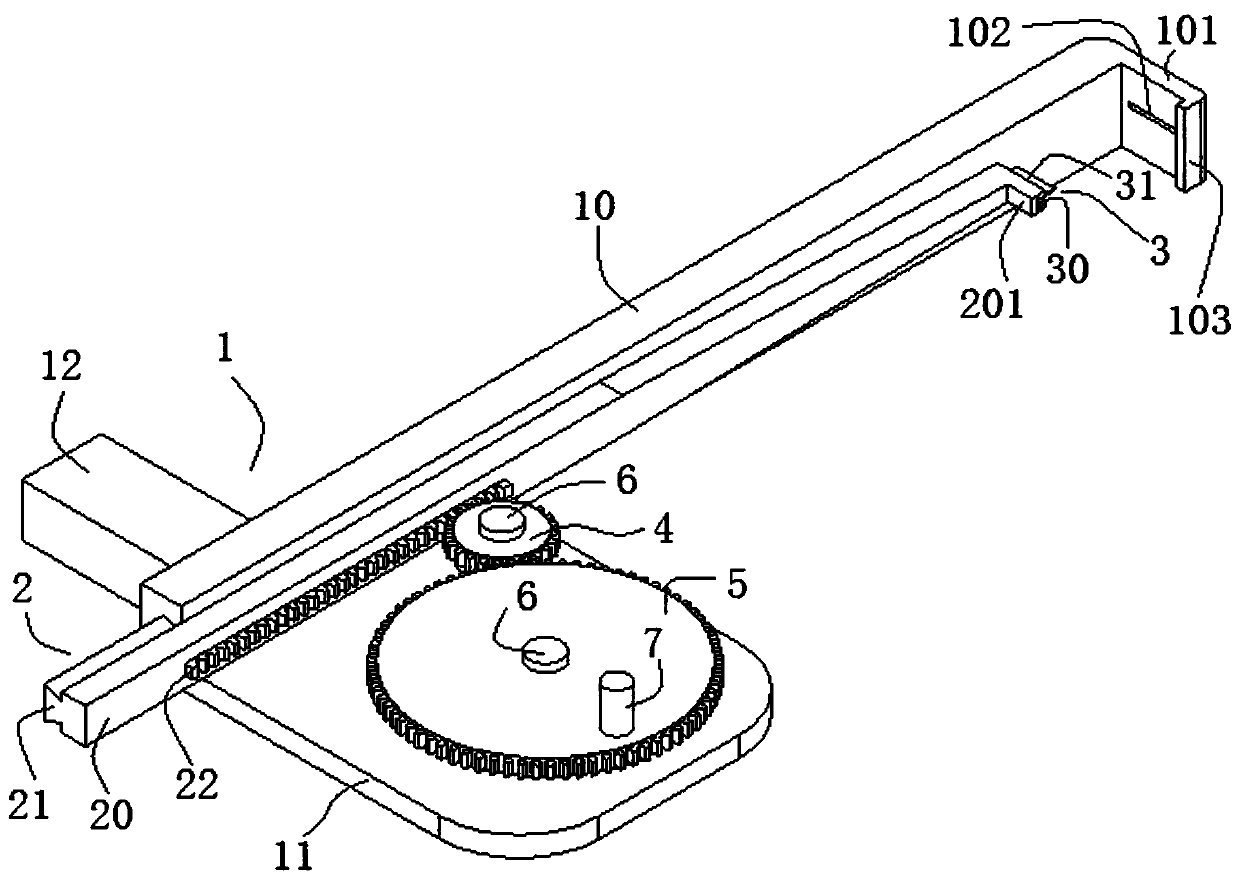

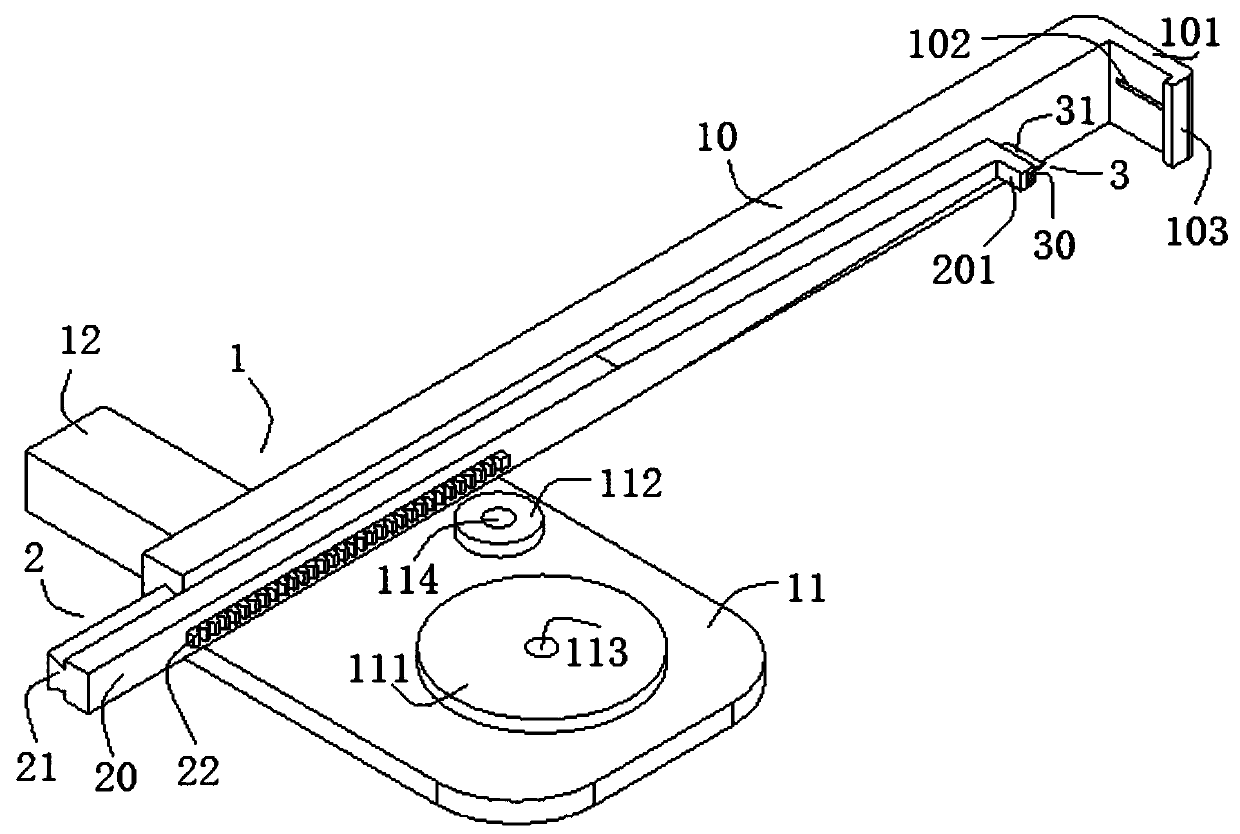

[0052] This embodiment provides a bone breaking device, such as Figure 1 to Figure 3 As shown, it includes: a base 1, a rod body structure 10 is provided on the base 1, one end of the rod body structure 10 is connected to the base 1, and the other end extends outward to form an extension end; On the rod body structure 10, the end of the extended end of the broken knife handle structure 2 near the rod body structure 10 is provided with a broken knife 3, and the end of the extended end of the rod body structure 10 is provided with a retaining hook structure for blocking the broken knife 3; the driving mechanism , which is connected with the breakaway handle structure 2, and is used to drive the breakaway knife handle structure 2 to move along the length direction of the rod structure 10 close to the retaining hook structure.

[0053] In this example, if Figure 1 to Figure 3 As shown, the base 1 is provided with a rod body structure 10, and the breaking tool handle structure 2...

Embodiment 2

[0071]The second embodiment is basically the same as the first embodiment, except that:

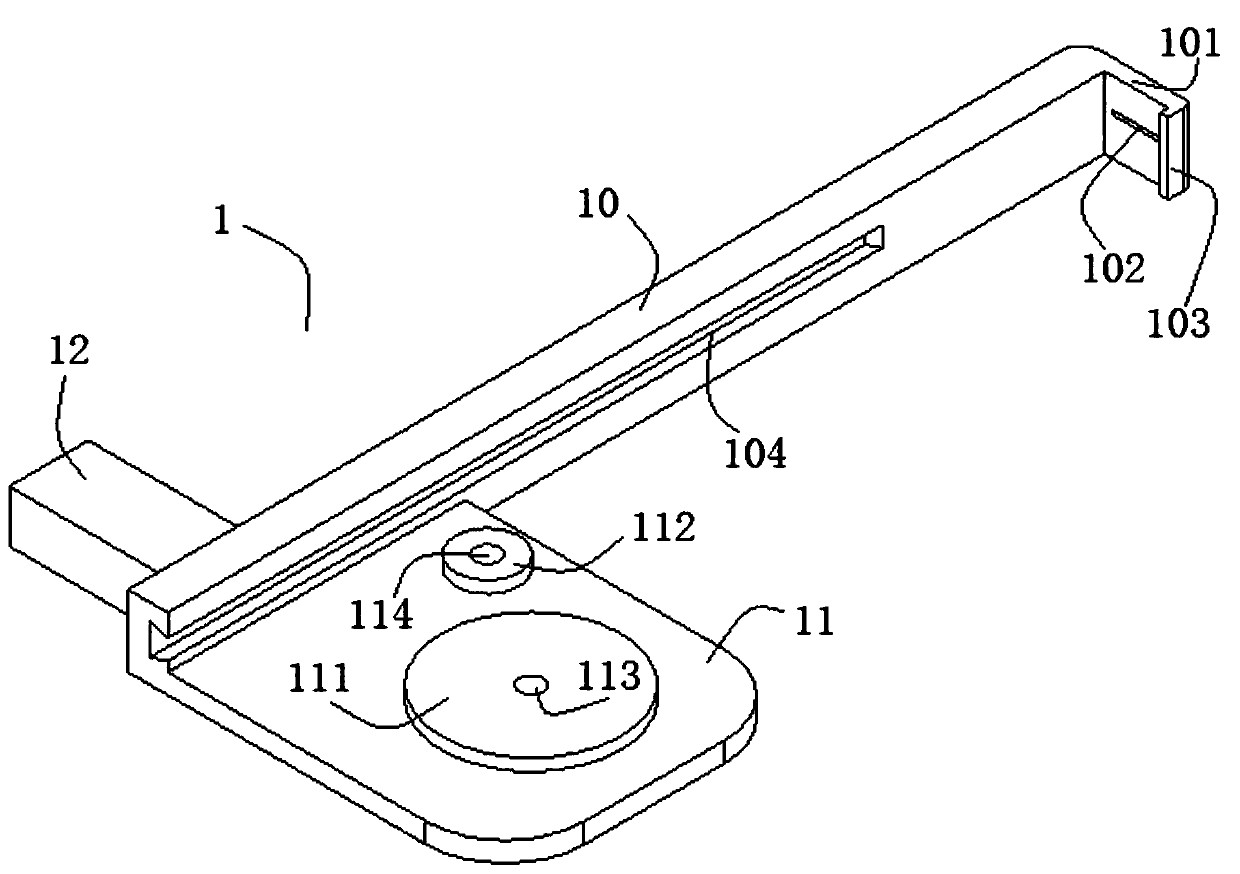

[0072] In this example, if Figure 7 , Figure 8 As shown, the guide groove 104 in this embodiment is provided on the upper side of the rod structure 10, the guide groove 104 extends from the front end surface of the rod structure 10 to the middle position of the rod structure 10, and the cross section of the guide groove 104 is an isosceles trapezoidal structure . In this embodiment, the front part of the knife handle body 20 is in the shape of a cuboid, and the end of the knife handle body 20 close to the blocking structure 101 is designed as a tapered wedge-shaped structure.

[0073] In this example, if Figure 7 , Figure 8 As shown, the blocking structure 101 is connected to the upper side of the rod structure 10, and the side of the blocking structure 101 facing the breaking knife 3 is provided with a groove 102 that can avoid the cutting edge of the breaking knife 3, which is b...

Embodiment 3

[0075] The third embodiment is basically the same as the first embodiment, except that:

[0076] In this embodiment, the rod body structure 10 includes a connected straight end and a curved end; one side of the straight end is provided with a guide groove 104 adapted to the guide slide rail 21 along the length direction of the straight end, and the guide groove 104 The curved end extends along the bending direction of the curved end, the cross section of the guide groove 104 is an arc-shaped hole, and the guide rail 21 is adapted to be slidably installed in the guide groove 104; the broken knife handle structure 2 includes a bendable curved knife handle structure and The drive handle body used to push the movement of the first connecting block 23; the curved handle structure includes the first connecting block 23 and the tail connecting block 25, the first connecting block 23 includes a body one 231, and a support protrusion one 233 for slidingly supporting the body one 231 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com