Yeast cell-based Ni-Co-S loaded porous carbon material as well as preparation method and application thereof

A technology of porous carbon materials and yeast cells, applied in the field of supercapacitors, can solve the problem that yeast cells are not resistant to metal salt solution, etc., and achieve the effect of improving capacitance performance, excellent capacitance performance and sustainable development performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

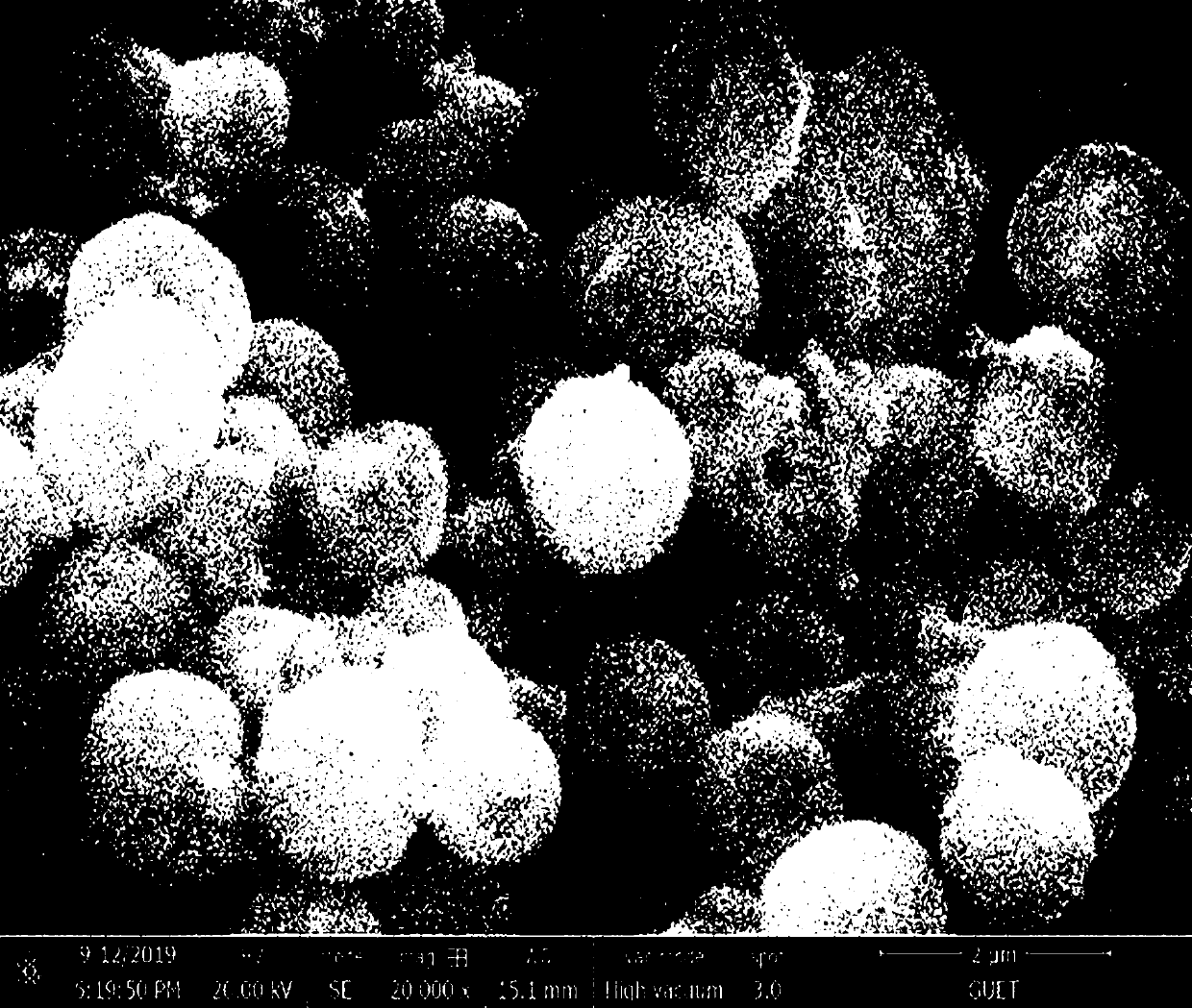

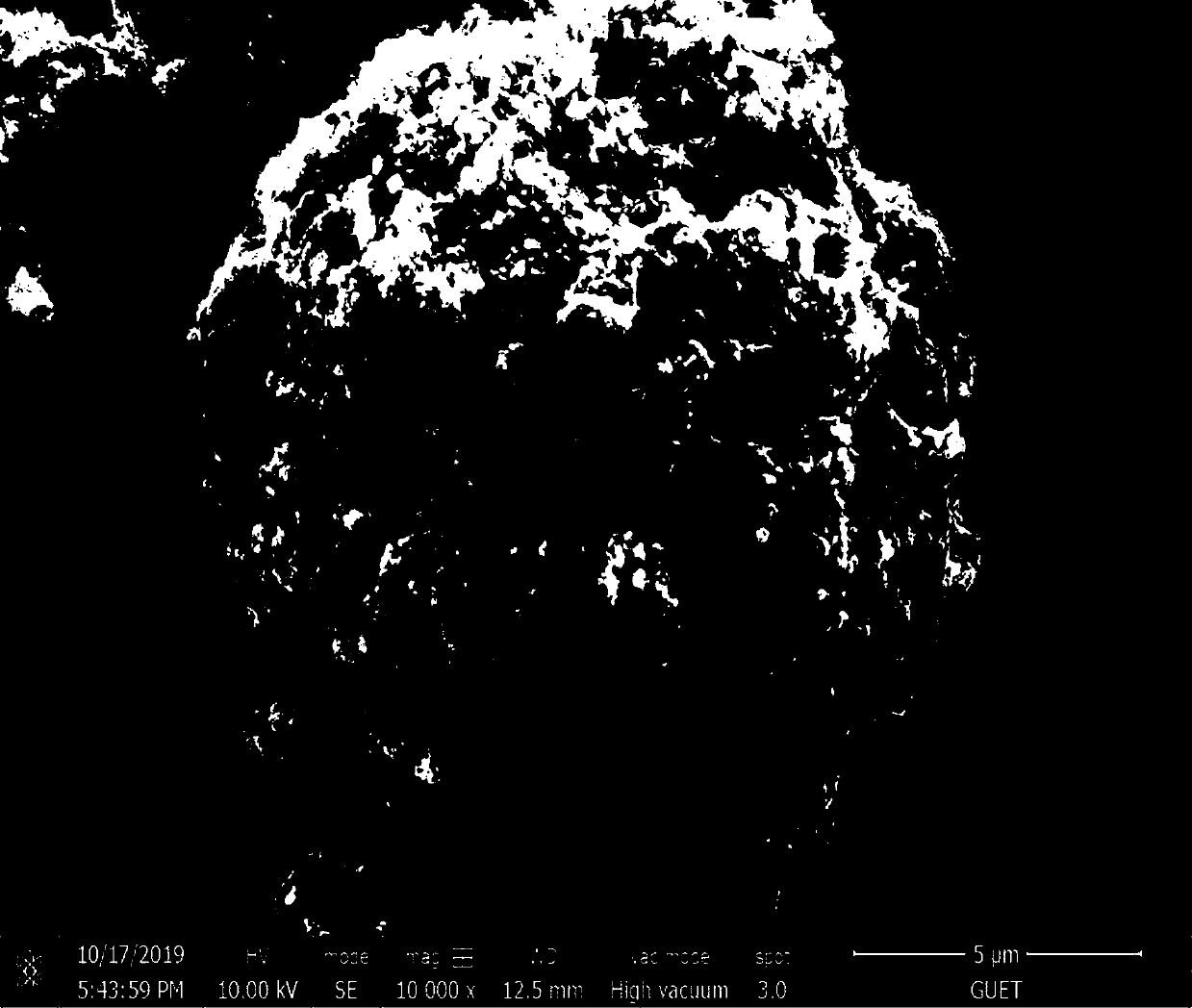

[0046] A method for preparing a supercapacitor material based on a yeast cell-loaded Ni-Co-S porous carbon material, comprising the following steps:

[0047] Step 1) Preparation of yeast cell porous carbon, prepare 0.024g / mL glucose solution, add yeast powder, incubate in a water bath at 37°C for 30min to pretreat yeast cells, wash and dry to obtain pretreated yeast cells, and then use Disperse the pretreated yeast cells with a concentration of 0.017g / mL in 3% glutaraldehyde aqueous solution and sonicate for 10min to disperse the yeast cells evenly, then conduct a hydrothermal reaction at 180°C for 5h. Washing, drying, and finally calcining at a temperature of 300°C for 2 hours in an air atmosphere, and then calcining at a temperature of 800°C for 2 hours under a nitrogen atmosphere, the yeast cell porous carbon can be obtained;

[0048] Step 2) The yeast cell porous carbon adsorbs cobalt and nickel metal ions, and weighs 0.5g of the yeast cell porous carbon obtained in step 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com