Temperature abnormal defect detecting and positioning method and system

A technology of abnormal defect and positioning method, applied in the field of abnormal temperature defect detection and positioning method and system, can solve the problems of high camera position requirements, difficult registration, insufficient judgment and positioning efficiency, etc., so as to improve registration efficiency and reduce computation. Quantity and temperature abnormality defect judgment and high positioning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

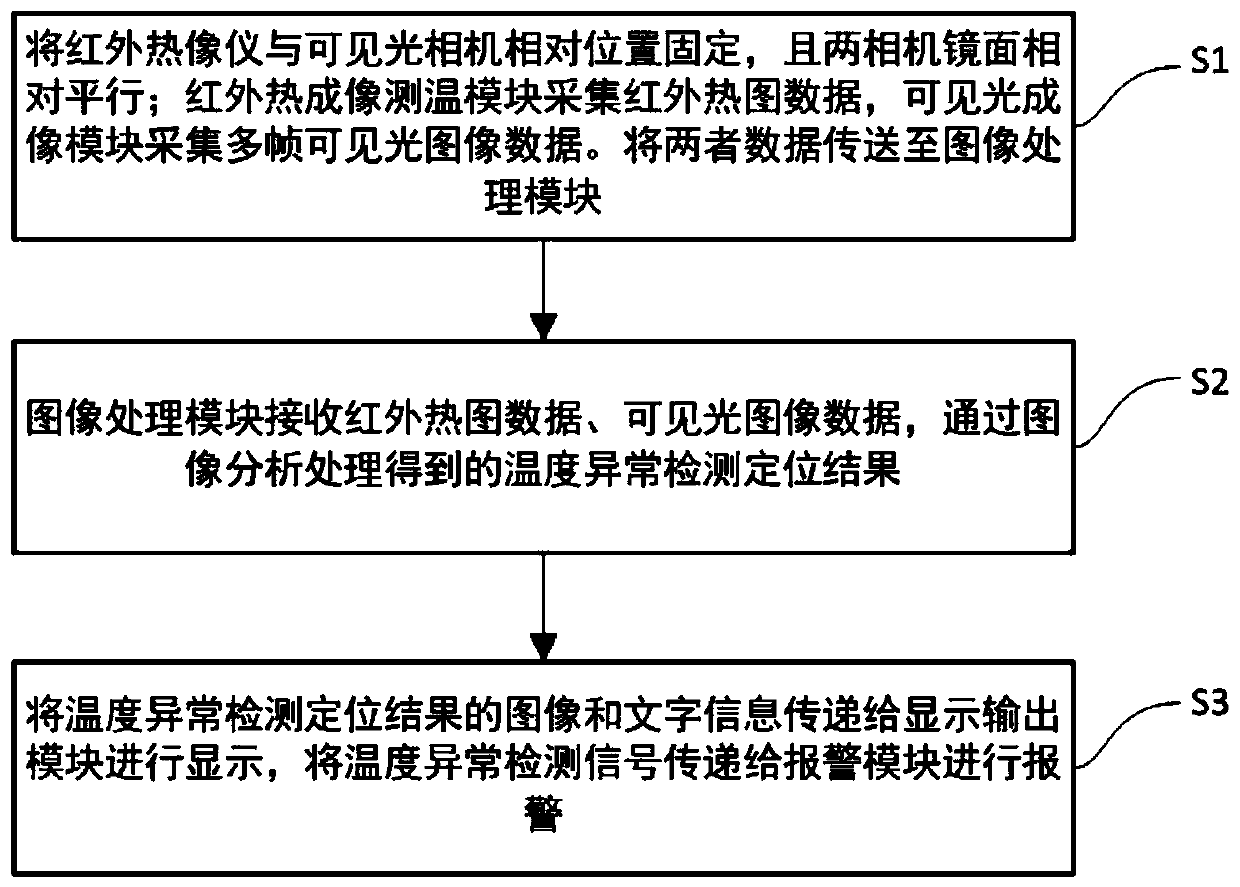

[0065] This embodiment provides a method for detecting and locating abnormal temperature defects, such as figure 1 As shown, the method includes the following steps:

[0066] S1: The relative positions of the infrared thermal imaging temperature measurement module and the visible light imaging module are fixed, and the mirror surfaces of the two are relatively parallel; the infrared thermal imaging temperature measurement module collects infrared heat map data, and the visible light imaging module collects visible light image data. Send the infrared heat map data and visible light image data to the image analysis and positioning module;

[0067] Wherein, in this embodiment, the infrared thermal imaging temperature measurement module is an infrared thermal imager, and the visible light imaging module is a visible light camera.

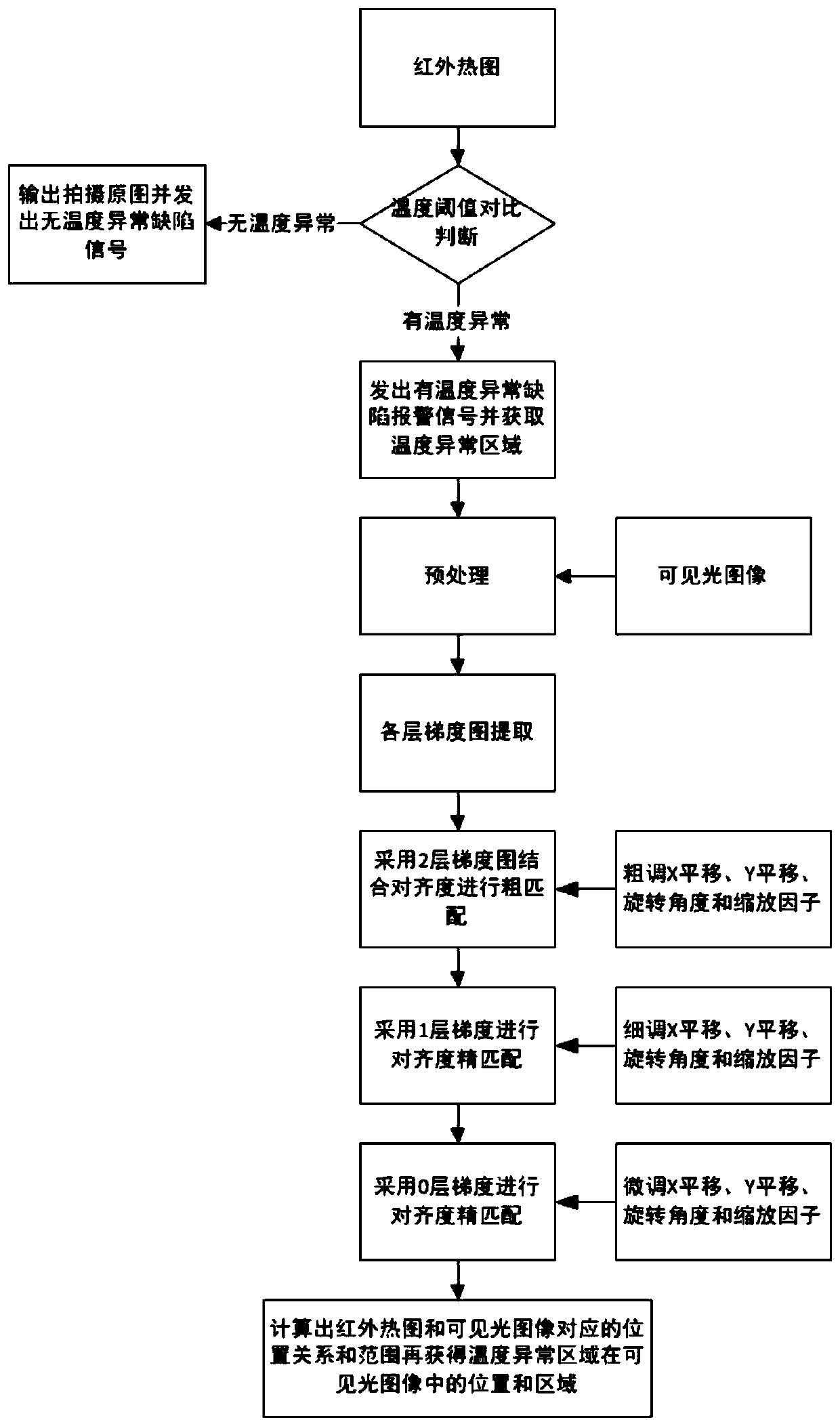

[0068] S2: The image analysis and positioning module receives infrared heat map data and visible light image data, and obtains temperature anomaly det...

Embodiment 2

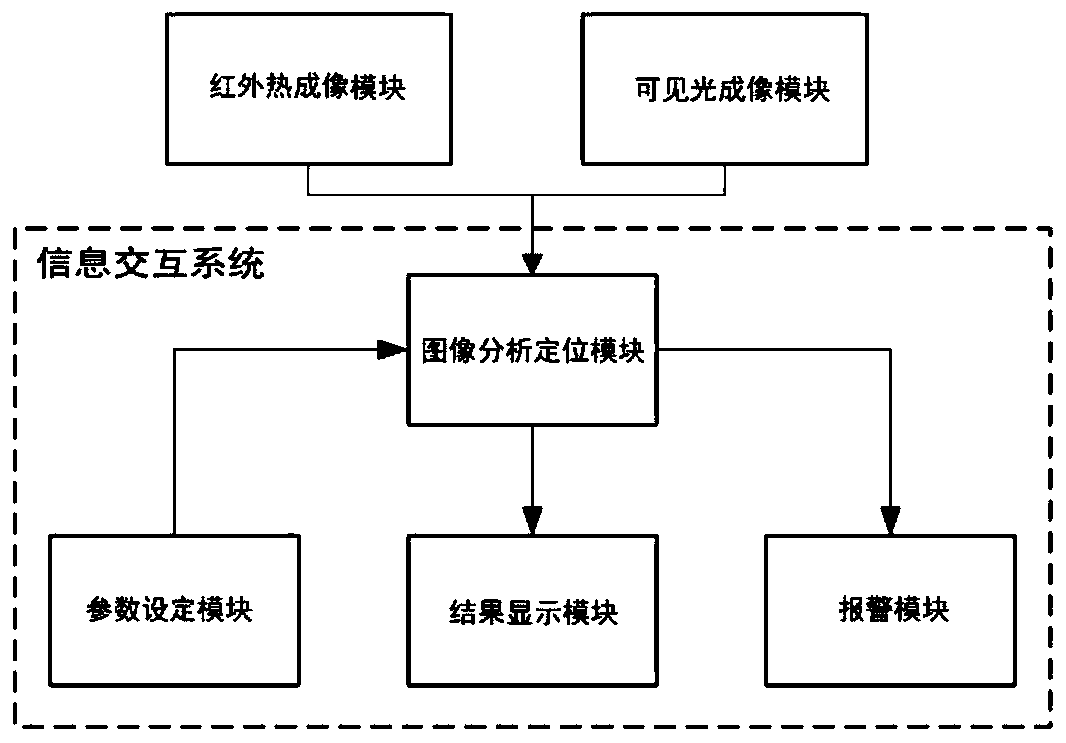

[0105] This embodiment provides a temperature anomaly defect detection and positioning system, such as image 3 As shown, the system includes: an infrared thermal imaging temperature measurement module, a visible light imaging module and an information interaction system, and the information interaction system includes a parameter setting module, a result display module, an alarm module, and an image analysis and positioning module; The imaging temperature measurement module collects the on-site infrared heat map, and transmits the infrared heat map data to the image analysis and positioning module; the visible light imaging module is used to collect the on-site visible light image, and transmits the visible light image data to the image analysis and positioning module; the parameters The setting module is used for the user to set the parameters of the infrared thermal imaging temperature measurement module, the parameter setting of the visible light imaging module, the result ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com