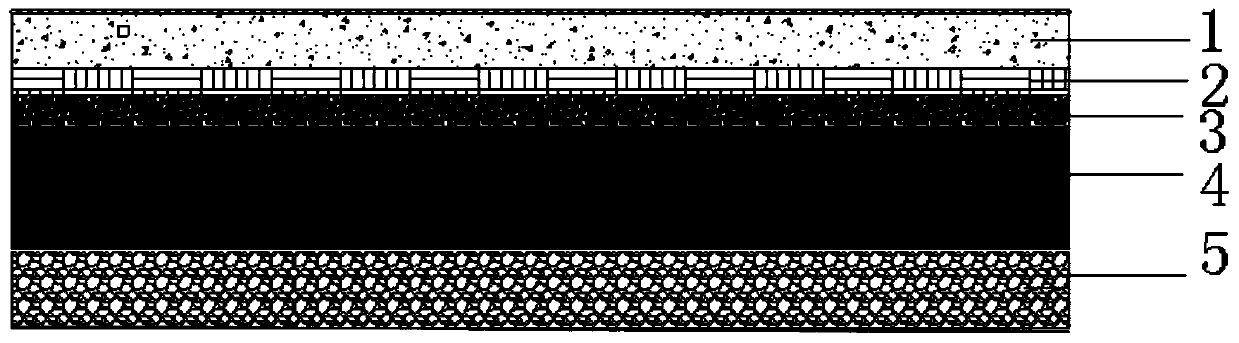

Asphalt concrete snow-melting and ice-inhibiting pavement structure

A technology of asphalt concrete and pavement structure, which is applied to the coagulation pavement, roads, roads and other directions paved on site, can solve the problems of loss of snow-melting and ice-suppressing materials, insufficient safety, road and environmental damage, etc., and improve road performance. , Improve durability, reduce freezing point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

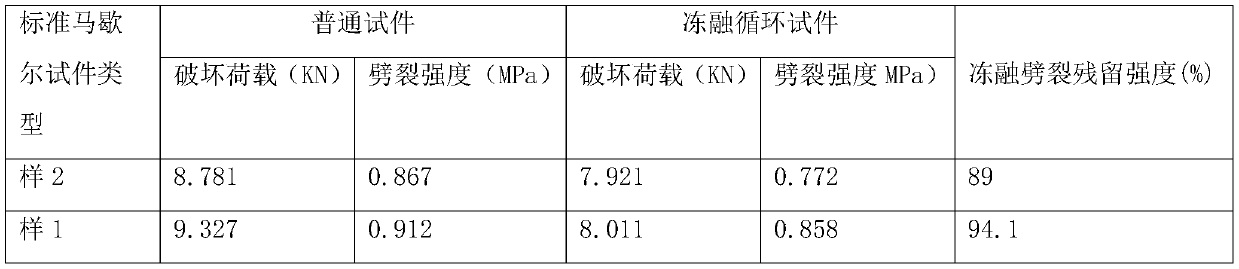

Embodiment 1

[0028] In the asphalt concrete snow-melting and ice-suppressing pavement structure of the present embodiment, the raw materials of the snow-melting and ice-suppressing materials include the following components by weight:

[0029] Biochemical humic acid 20 parts, wood vinegar 10 parts, starch-acrylic acid graft copolymer 5 parts, chloroprene emulsion 5 parts, epoxy resin 5 parts, phthalimide 4 parts, isopropyl benzoate 3 parts of ester, 2 parts of polyester acrylate, 1 part of β-hydroxybutyraldehyde, 8 parts of thiourea, 1 part of sorbic acid fatty acid ester, 0.5 part of coupling agent, polyether modified heptamethyltrisiloxane 1 part, 1 part of long-chain alkanes, 1 part of corrosion inhibitor.

Embodiment 2

[0031] In the asphalt concrete snow-melting and ice-suppressing pavement structure of the present embodiment, the raw materials of the snow-melting and ice-suppressing materials include the following components by weight:

[0032] 30 parts of biochemical humic acid, 20 parts of wood vinegar, 15 parts of starch-acrylic acid graft copolymer, 10 parts of chloroprene emulsion, 10 parts of epoxy resin, 8 parts of phthalimide, isopropyl benzoate 6 parts of ester, 4 parts of polyester acrylate, 3 parts of β-hydroxybutyraldehyde, 13 parts of thiourea, 5 parts of sorbic acid fatty acid ester, 2 parts of coupling agent, polyether modified heptamethyltrisiloxane 5 parts, long-chain alkanes 5 parts, corrosion inhibitor 3 parts.

Embodiment 3

[0034] In the asphalt concrete snow-melting and ice-suppressing pavement structure of the present embodiment, the raw materials of the snow-melting and ice-suppressing materials include the following components by weight:

[0035] 20 parts of biochemical humic acid, 20 parts of wood vinegar, 5 parts of starch-acrylic acid graft copolymer, 10 parts of chloroprene emulsion, 5 parts of epoxy resin, 8 parts of phthalimide, isopropyl benzoate 3 parts of ester, 4 parts of polyester acrylate, 1 part of β-hydroxybutyraldehyde, 13 parts of thiourea, 1 part of sorbic acid fatty acid ester, 2 parts of coupling agent, polyether modified heptamethyltrisiloxane 1 part, 5 parts of long-chain alkanes, 1 part of corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com