High-precision coated pad for PCB drilling

A high-precision, coating technology, used in coatings, polyamide coatings, etc., can solve the problems of easy moisture absorption, poor flatness, and large warpage of the backing plate for PCB drilling. Good wear and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

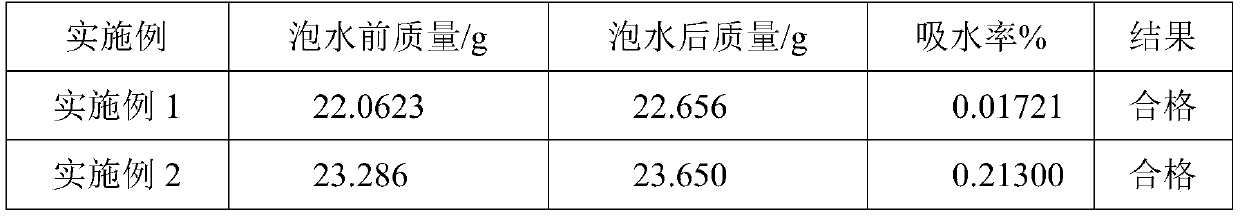

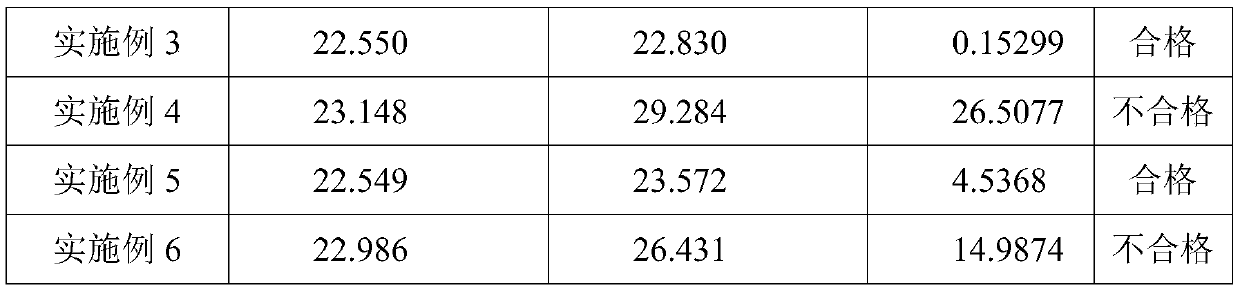

Examples

preparation example Construction

[0057] In the present invention, the preparation method of the coating at least includes the following steps:

[0058] (1) Mix the resin with water at room temperature and stir for 15-30min;

[0059] (2) Add filler, thickener, defoamer, antistatic agent to step (1) successively and stir for 20-40min;

[0060] (3) Before use, add curing agent to step (2), stir evenly, and get the product after discharging;

[0061] Most preferably, the coating is used within 48 hours after preparation.

[0062] In the present invention, adding the curing agent before use can avoid the phenomenon of polyethylene wax demulsification caused by the curing agent. The inventor thinks that the possible reason is: adding the curing agent before use can weaken the effect of the curing agent on the demulsification of the emulsified wax, inhibit the demulsification of the emulsified wax, prolong the demulsification time, and make the polyethylene wax form a uniform layer on the backing plate. Wax film,...

Embodiment 1

[0072] Embodiment 1 provides a kind of high-precision coating backing plate for PCB drilling, and the coating backing plate includes a base material and a coating coated on the upper and lower surfaces of the base material; wherein, the coating, by weight In terms of parts, at least include: 35 parts of resin, 61 parts of filler, 32 parts of thickener, 2 parts of defoamer, 2 parts of antistatic agent, 3 parts of curing agent, and 52 parts of water.

[0073] The base material is wood fiber board, purchased from Jiangsu Xinsu Building Materials Co., Ltd.

[0074] The resin is urea-formaldehyde resin, purchased from Shandong Moore Chemical Co., Ltd.

[0075] The filler is a combination of gypsum powder and titanium dioxide with a weight ratio of 1.5:1.

[0076] The thickener is a combination of erucamide, oleamide, polyamide wax and polyethylene wax, and the weight ratio is 6:5:1:4.

[0077] The defoamer is polysiloxane, purchased from Guangdong Zhongbang Fine Chemical Co., Ltd...

Embodiment 2

[0089] Embodiment 2 provides a kind of high-precision coating backing plate for PCB drilling, and the coating backing plate includes a base material and a coating coated on the upper and lower surfaces of the base material; wherein, the coating, by weight In terms of parts, at least include: 20 parts of resin, 50 parts of filler, 20 parts of thickener, 1 part of defoamer, 1 part of antistatic agent, 1 part of curing agent, and 45 parts of water.

[0090] The base material is wood fiber board, purchased from Jiangsu Xinsu Building Materials Co., Ltd.

[0091] The resin is urea-formaldehyde resin, purchased from Shandong Moore Chemical Co., Ltd.

[0092] The filler is a combination of gypsum powder and titanium dioxide with a weight ratio of 1:1.

[0093] The thickener is a combination of erucamide, oleamide, polyamide wax and polyethylene wax, and the weight ratio is 4:3:0.5:3.

[0094] The defoamer is polysiloxane, purchased from Guangdong Zhongbang Fine Chemical Co., Ltd. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com