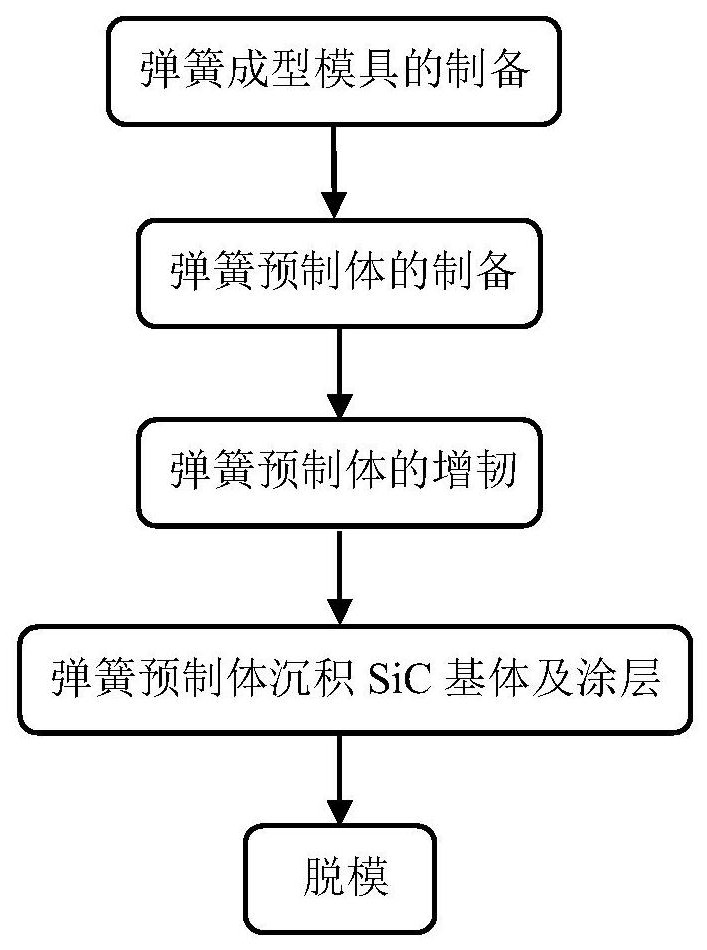

A kind of preparation method of continuous fiber reinforced c/sic ceramic spring

A continuous fiber and ceramic technology, used in spring/shock absorber manufacturing, springs, low internal friction springs, etc., can solve the problems of difficult processing, uneven distribution of carbon layers, uncontrollable thickness, etc., to achieve high efficiency, repeatability, The effect of excellent designability and precise controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] 1. Preparation of a spring molding die

[0029] According to the mechanical design parameters required by the spring, a cylindrical ceramic mold which can be opened and closed, has threads all over its body and through holes distributed among the threads is obtained through 3D software design and 3D printing. The design concept of the die is mainly divided into two aspects. On the one hand, in order to ensure the smooth demoulding of the spring and the repeated utilization of the die, the die is divided into three parts along the axial direction, with threads on both sides of the die and through holes distributed among the threads. For easy drawing, the middle die is longer than the other two parts, with no threads on the side and only through holes distributed in a spiral line. On the other hand, in order to ensure the stability of the mechanical parameters of the spring and the adequacy of the deposition process, the whole die is designed as a hollow cylinder, the threads...

Embodiment 1

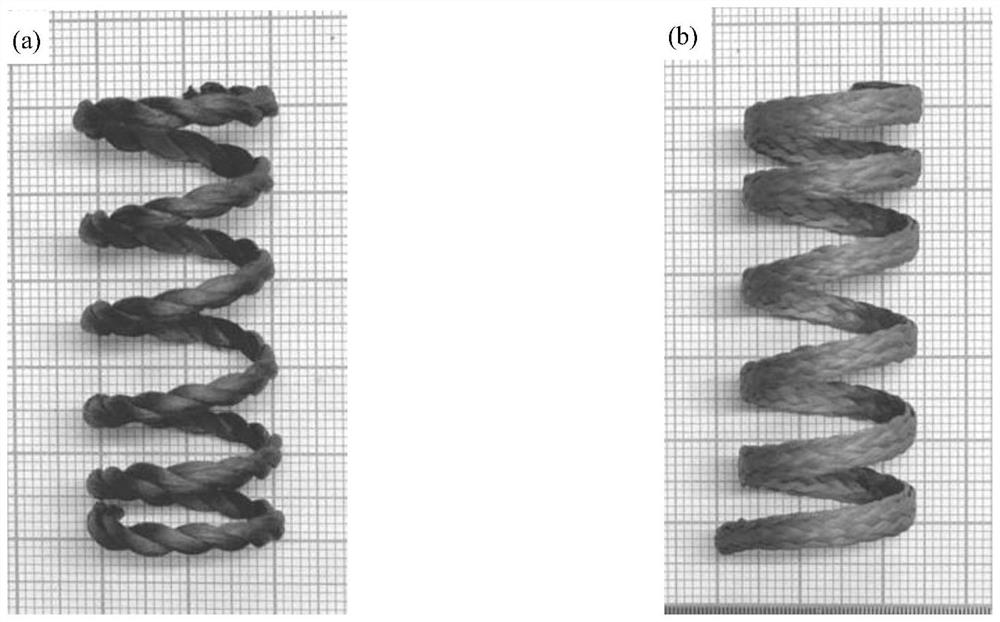

[0040] One such as Figure 2 (a) The stiffness of the ceramic matrix composite spring of the present invention reaches 2.254N / mm at room temperature, and still reaches 2.120N / mm in air at 1000℃, with a stiffness retention rate of about 97.6%.

[0041] 1, preparing a spring molding die

[0042] According to the mechanical design manual, design the mechanical design parameters of the spring as shown in Table 1. Through 3D software design and 3D printing, a cylindrical ceramic mold which can be opened and closed, with threads all over the body and through holes distributed among the threads can be obtained. The design concept of the die is mainly divided into two aspects. On the one hand, in order to ensure the smooth demoulding of the spring and the repeated utilization of the die, the die is divided into three parts along the axial direction, with threads on both sides of the die and through holes distributed among the threads. For the convenience of drawing, the middle die is longe...

Embodiment 2

[0048] One such as Figure 2 (b) The stiffness of the ceramic matrix composite spring of the present invention reaches 2.276N / mm at room temperature.

[0049] 1, preparing a spring molding die

[0050] According to the mechanical design manual, design the mechanical design parameters of the spring as shown in Table 1. Through 3D software design and 3D printing, a cylindrical ceramic mold which can be opened and closed, with threads all over the body and through holes distributed among the threads can be obtained. The design concept of the die is mainly divided into two aspects. On the one hand, in order to ensure the smooth demoulding of the spring and the repeated utilization of the die, the die is divided into three parts along the axial direction, with threads on both sides of the die and through holes distributed among the threads. For the convenience of drawing, the middle die is longer than the other two parts, with no threads on the side and only through holes distributed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com