High-strength light aggregate concrete and preparation process thereof

A lightweight aggregate concrete, high-strength technology, applied in the field of concrete, can solve the problems of reduced strength of lightweight aggregate concrete, cracking of concrete layers, difficult work performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Preparation example of polypropylene / graphene oxide composite fiber

[0048] Step 1: Select polypropylene particles, crush them into powder with a plastic crusher, sieve the polypropylene powder with a particle size less than 1mm, and collect them for later use;

[0049] Step 2: Pour the ethanol solution into the polypropylene powder with a particle size of less than 1mm until the ethanol solution is submerged in the polypropylene powder, stir and mix evenly, put it into a ball mill for fine grinding for 8 hours, and set the speed of the ball mill to 100rad / min , after finishing fine grinding, dry it for later use;

[0050]Step 3: Add graphene oxide solution and ethylene solution 1:1 to the polypropylene powder that has been finely ground in step 2 to make a mixed solution, ultrasonic for 0.5h, and continue stirring with a stirrer during the ultrasonic process;

[0051] Step 4: Precipitate the mixed solution obtained by ultrasonic operation in Step 3 for 24 hours;

[...

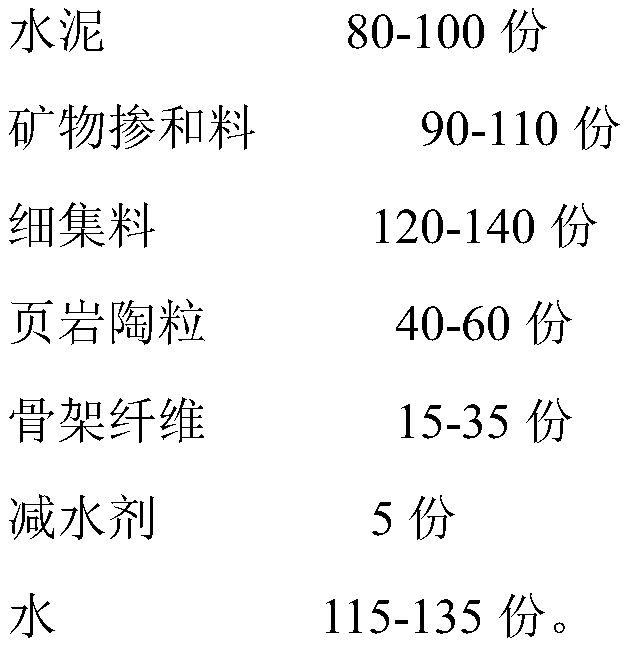

Embodiment 1

[0057] High-strength lightweight aggregate concrete includes the following weight components: cement 80kg, mineral admixture 110kg, fine aggregate 140kg, shale ceramsite 40kg, water reducing agent 5kg, water 135kg, skeleton fiber 15kg.

[0058] The cement is ordinary Portland cement or sulphoaluminate cement.

[0059] Mineral admixtures include fly ash.

[0060] The fine aggregate is medium sand with a fineness modulus of 2.5-2.8 and a weight of 140kg.

[0061] The water reducer is sodium lignosulfonate or melamine water reducer.

[0062] Skeleton fibers include polypropylene / graphene oxide composite fibers and steel fibers, specifically polypropylene / graphene oxide composite fibers are 5kg and steel fibers are 10kg.

[0063] The preparation process of the skeleton fiber: cut the prepared polypropylene / graphene oxide composite fiber so that the length of the polypropylene / graphene oxide composite fiber is between 12-15mm, screen the steel fiber with a length of 6-9mm, and se...

Embodiment 2

[0066] The difference between Example 2 and Example 1 lies in the different contents of concrete components and the different parameters of the high-strength concrete preparation process.

[0067] See Table 1 and Table 2 for components.

[0068] The preparation process of the skeleton fiber: cut the prepared polypropylene / graphene oxide composite fiber so that the length of the polypropylene / graphene oxide composite fiber is between 12-15mm, screen the steel fiber with a length of 6-9mm, and send to Steel fibers are added to the polypropylene / graphene oxide composite fiber; after the polypropylene / graphene oxide composite fiber and the steel fiber are prepared in proportion, they are stirred and mixed evenly to obtain the skeleton fiber.

[0069] The preparation process of high-strength lightweight aggregate concrete: mix cement, mineral admixture, fine aggregate, shale ceramsite and skeleton fiber in proportion to form a component A mixture for later use; add water reducing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com