Printing head, printing method, printing system, storage medium and printer

A printing head and nozzle technology, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve problems such as hindering board work, affecting work efficiency and work accuracy, and affecting board work, so as to ensure normal and stable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

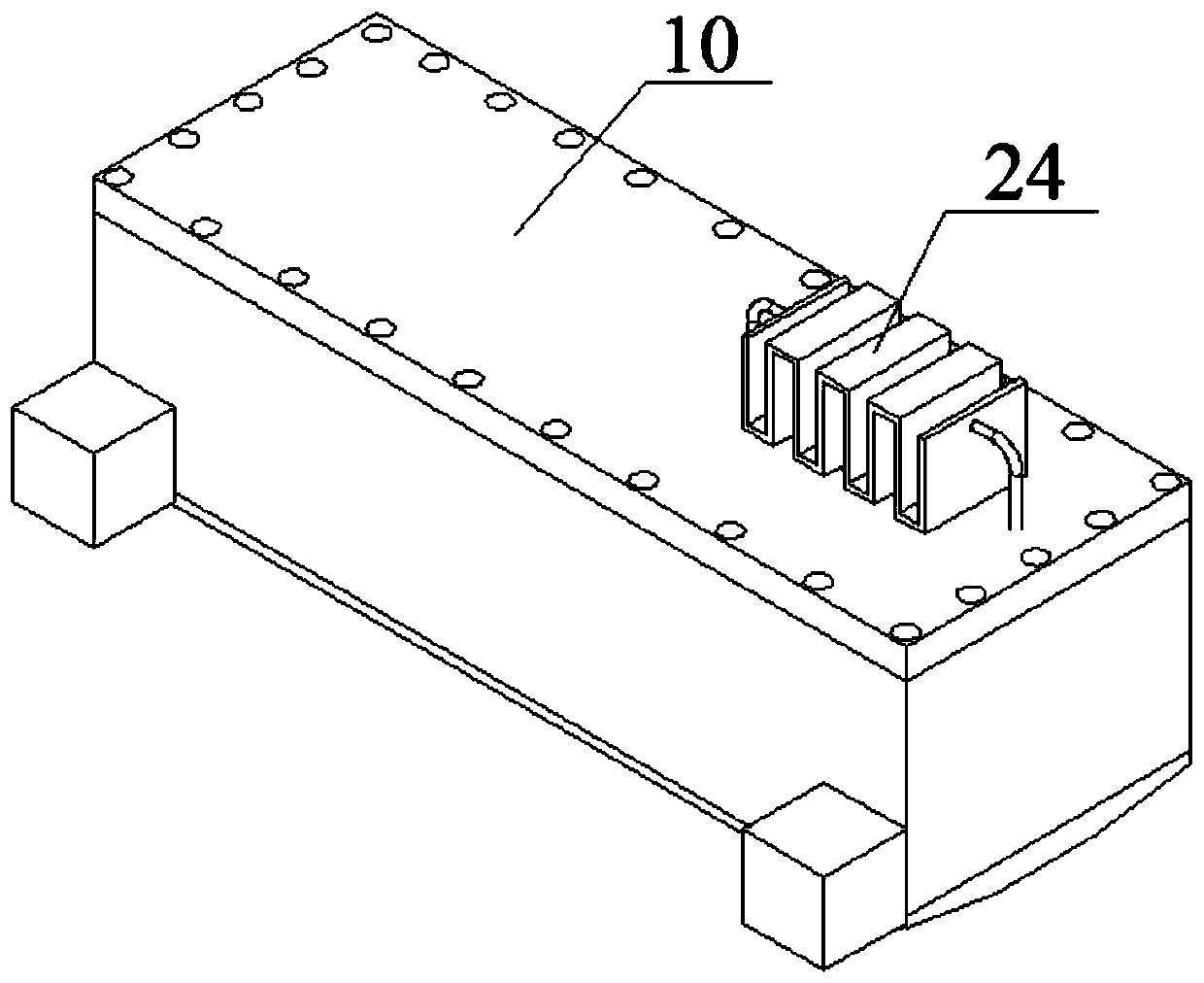

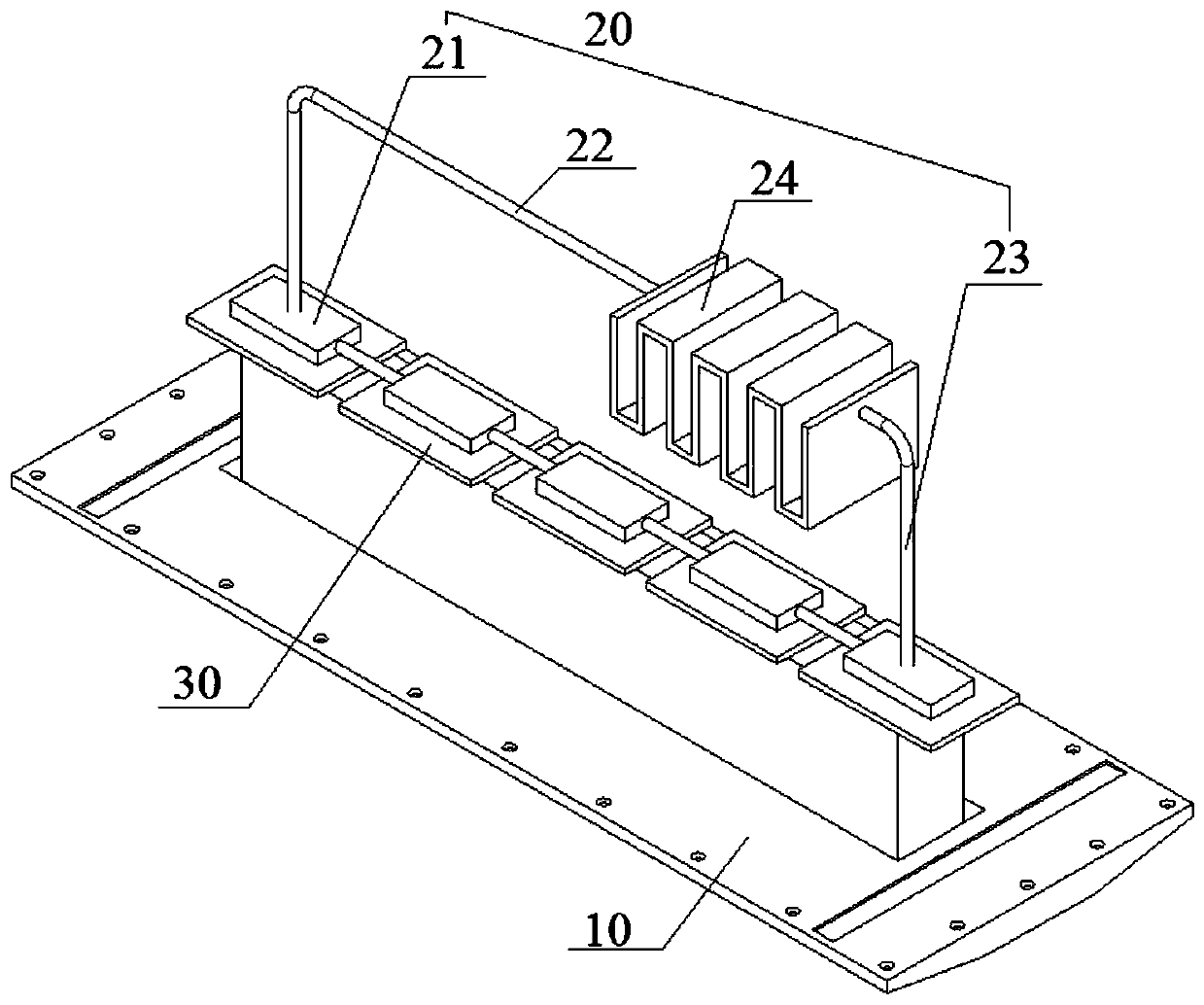

[0129] Refer to attached figure 1 And attached figure 2 As shown, a print head includes a housing 10, a thermostat 20 and a board 30, the thermostat 20 is in contact with the board 30, and the thermostat 20 includes a heat exchange block 21, a liquid inlet pipe 22, an outlet Liquid pipe 23, No. 1 circulation pump, and No. 1 radiator 24. One end of the heat exchange block 21 communicates with the liquid inlet pipe 22, and the opposite end communicates with the liquid outlet pipe 23. The No. 1 radiator 24 One end is communicated with the described liquid inlet pipe 22, and the opposite end of the No. 1 radiator 24 is communicated with the described liquid outlet pipe 23, and the described liquid inlet pipe 22 or the described liquid outlet pipe 23 is provided with the No. 1 circulation pump, the No. 1 radiator 24, the liquid inlet pipe 22, the heat exchange block 21, the liquid outlet pipe 23, and the No. 1 circulation pump are connected to form a cooling passage; the casing 1...

Embodiment 2

[0133] On the basis of embodiment 1, a kind of printing head also comprises ink heating device 40, and described ink heating device 40 comprises ink cartridge 41, ink inlet pipe 42, ink outlet pipe 43, No. 2 circulation pump, and described ink cartridge 41 is arranged on Inside the housing 10, one end of the heat exchange block 21 communicates with the ink inlet pipe 42, and the opposite end communicates with the ink outlet pipe 43, and one end of the ink cartridge 41 communicates with the ink inlet pipe 42, And the opposite end of the ink cartridge 41 communicates with the ink outlet pipe 43, the No. 2 circulation pump is set on the ink inlet pipe 42 or the ink outlet pipe 43, the ink cartridge 41, the ink inlet pipe 42. The heat exchange block 21, the ink outlet pipe 43, and the No. 2 circulating pump are connected to form an ink heating passage.

[0134] The heat exchange block 21 includes an ink pipeline 210 and a liquid pipeline 211. The ink pipeline 210 is in a zigzag sh...

Embodiment 3

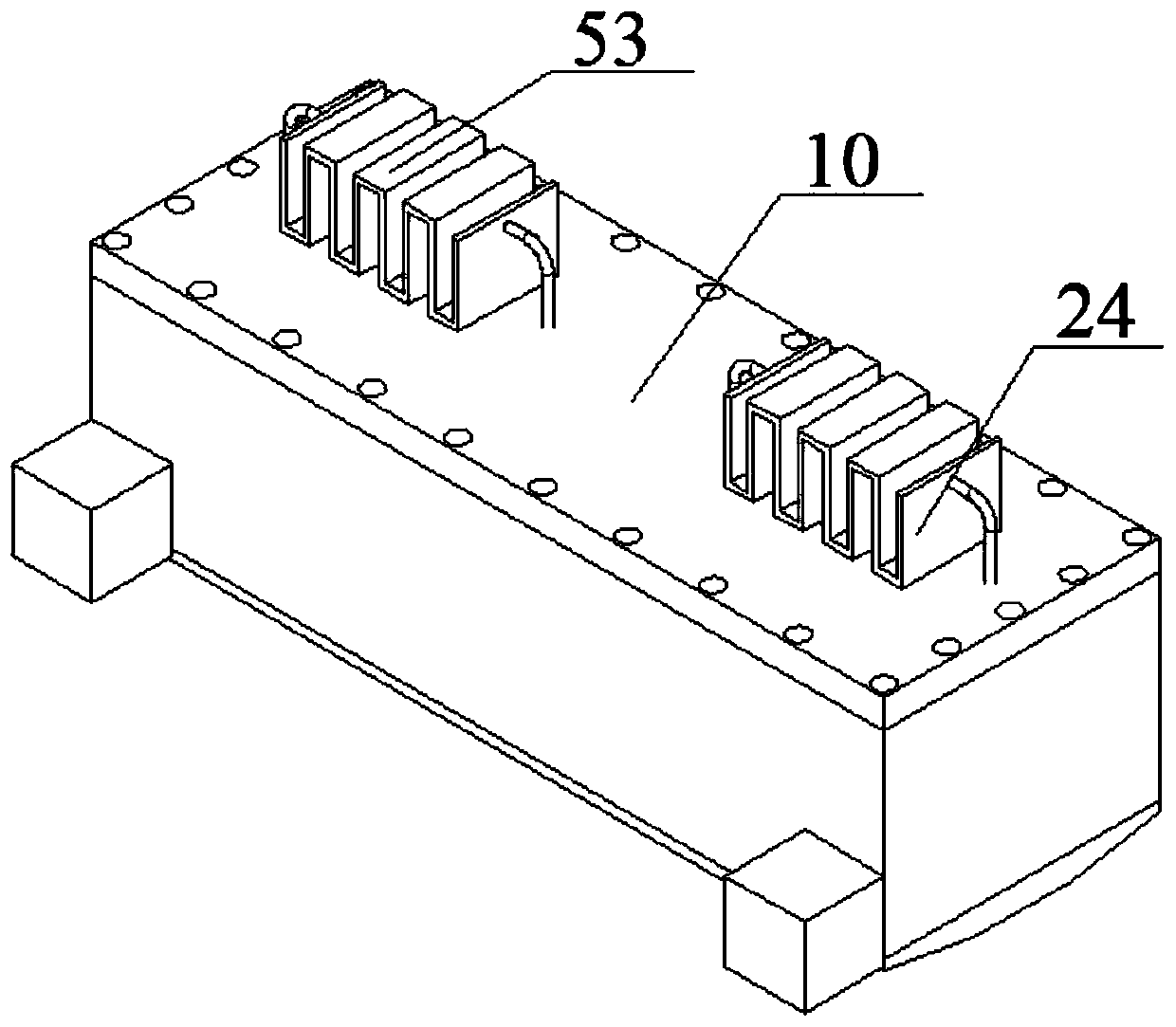

[0137] Refer to attached image 3 and 4As shown, on the basis of Embodiment 2, a print head further includes an ink cooling device 50, and the ink cooling device 50 includes an ink supply tube 51, an ink delivery tube 52, a No. 3 circulation pump, and a No. 2 radiator 53. The No. 2 radiator 53 is arranged outside the housing 10, one end of the ink cartridge 41 communicates with the ink supply tube 51, and the opposite end communicates with the ink delivery tube 52. The No. 2 radiator communicates with the ink supply tube 51. One end of 53 communicates with the ink supply pipe 51, and the opposite end communicates with the ink supply pipe 52. The No. 3 circulation pump is arranged on the ink supply pipe 51 or the ink supply pipe 52, and the The ink cartridge 41 , the ink supply pipe 51 , the No. 2 radiator 53 , the ink delivery pipe 52 , and the No. 3 circulating pump are connected to form an ink cooling passage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com