Precious metal-free dolomite catalyst and preparation method and application thereof

A technology of dolomite and precious metals, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., which can solve problems such as cracking catalyst poisoning, poor catalytic selectivity, and insufficient mechanical strength , to achieve the effect of not easy poisoning, stable performance, high mechanical strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

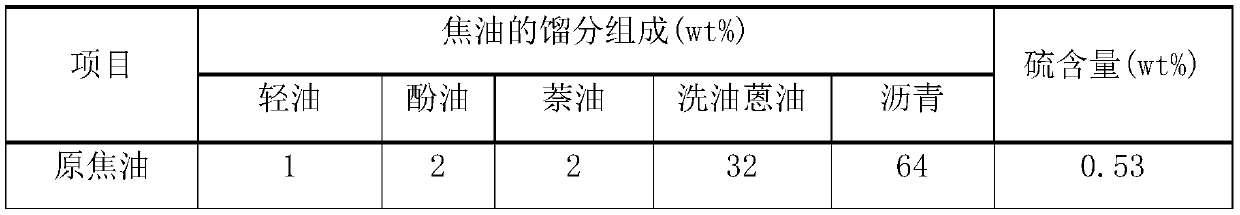

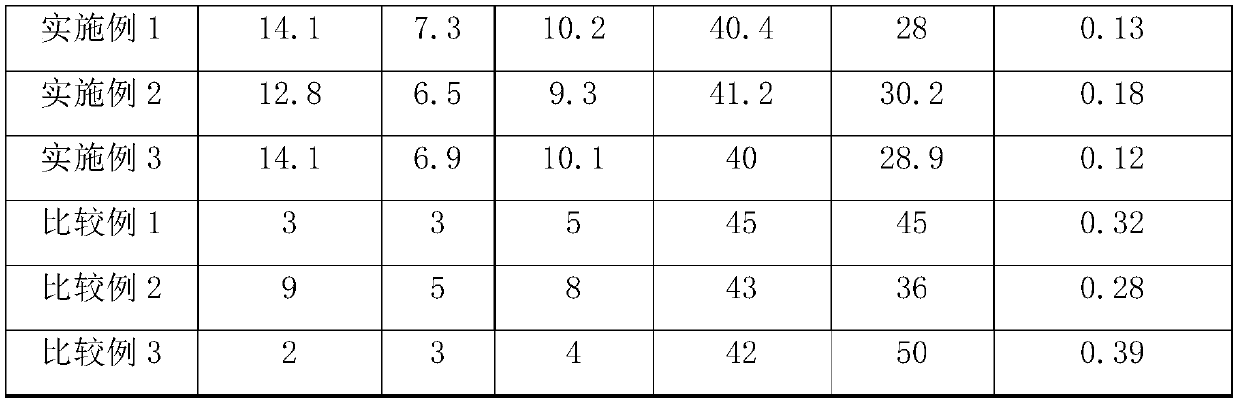

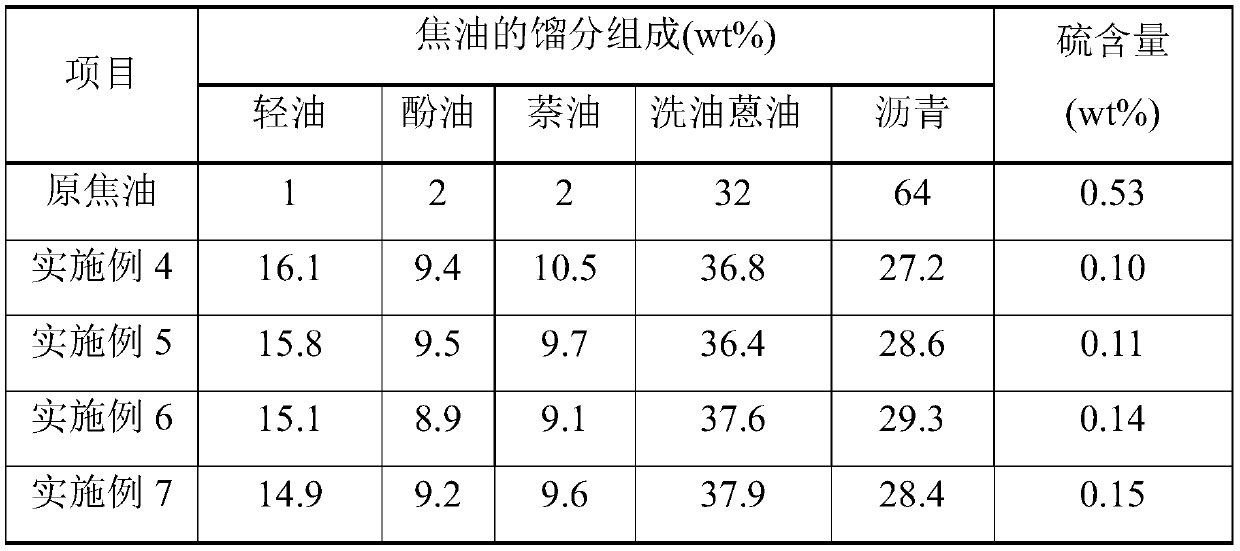

Embodiment 1

[0061] Select natural dolomite as raw material and pretreat it: grind the dolomite, soak it with deionized water, filter, dry at 100°C for 24h, vacuumize (vacuum degree is 0.07MPa, time 6h), grind Cross 120 mesh sieves to obtain dolomite powder; use nickel nitrate, iron nitrate (the mass ratio of the two in the precursor solution is 1:1.3, nickel nitrate 3%, iron nitrate 3.9%) and water to configure the precursor solution, and the Ni load is controlled as 2%, the Fe load is 4% (that is, the content of nickel oxide after calcination is 2%, and the content of iron oxide is 4%), and the equal volume impregnation method is used to impregnate dolomite powder (ultrasonic 6h, total impregnation time 24h), and then Dry, grind, and pass through a 120-mesh sieve; add 8% of the binder aluminum sol, 2% of the thickener methyl cellulose, and 1% of the extrusion aid kale powder to the 89% of the impregnated powder according to the mass percentage, and add an appropriate amount Deionized wat...

Embodiment 2

[0064] Select natural dolomite as raw material and pretreat it: grind the dolomite, soak it with deionized water, filter, dry at 110°C for 22h, vacuumize (vacuum degree is 0.08MPa, time 8h), grind Cross 100 mesh sieves to obtain dolomite powder; use nickel nitrate, iron nitrate (the mass ratio of the two in the precursor solution is 1:1.2, nickel nitrate 2.4%, iron nitrate 2.88%) and water to configure the precursor solution, and the Ni load is controlled as 1%, the Fe load is 2% (that is, the content of nickel oxide after calcination is 1%, and the content of iron oxide is 2%), and the equal volume impregnation method is used to impregnate dolomite powder (ultrasonic 5h, total impregnation time 20h), and then Dry, grind, and pass through a 100-mesh sieve; add 10% of binder silica sol, 3% of thickener methyl cellulose, and 2% of extrusion aid kale powder to 85% of the impregnated powder according to the mass percentage, and add appropriate amount Deionized water, and 8ml / 100g ...

Embodiment 3

[0067] Select natural dolomite as raw material and pretreat it: grind the dolomite, soak it with deionized water, filter, dry at 120°C for 20h, vacuumize (vacuum degree is 0.10MPa, time 10h), grind Cross 110 mesh sieves to obtain dolomite powder; use nickel nitrate, ferric nitrate (the mass ratio of the two in the precursor solution is 1:1.4, nickel nitrate 9%, ferric nitrate 12.6%) and water to configure the precursor solution, and the Ni load is controlled as 5%, the Fe load is 10% (that is, the content of nickel oxide after calcination is 5%, and the content of iron oxide is 10%), using the equal volume impregnation method, impregnating dolomite powder (ultrasonic 10h, total impregnation time 28h), and then Drying, grinding, and passing through a 110-mesh sieve; according to the mass percentage, add 5% of the binder pseudo-boehmite, 1% of the thickener methylcellulose, and 0.5% of the extrusion aid scallop powder to 93.5% of the impregnated powder , add an appropriate amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com