Pixel arrangement display equipment capable of improving pixel resolution and evaporation method

A technology of pixel resolution and pixel arrangement, which is applied in the field of OLED device manufacturing, can solve the problems of increasing FMM cleaning frequency, increasing process steps, and waste of evaporation materials, so as to achieve large evaporation alignment margin, improve device resolution, and improve The effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment discloses as Figure 7 A pixel arrangement evaporation method that can improve pixel resolution is shown, comprising the following steps:

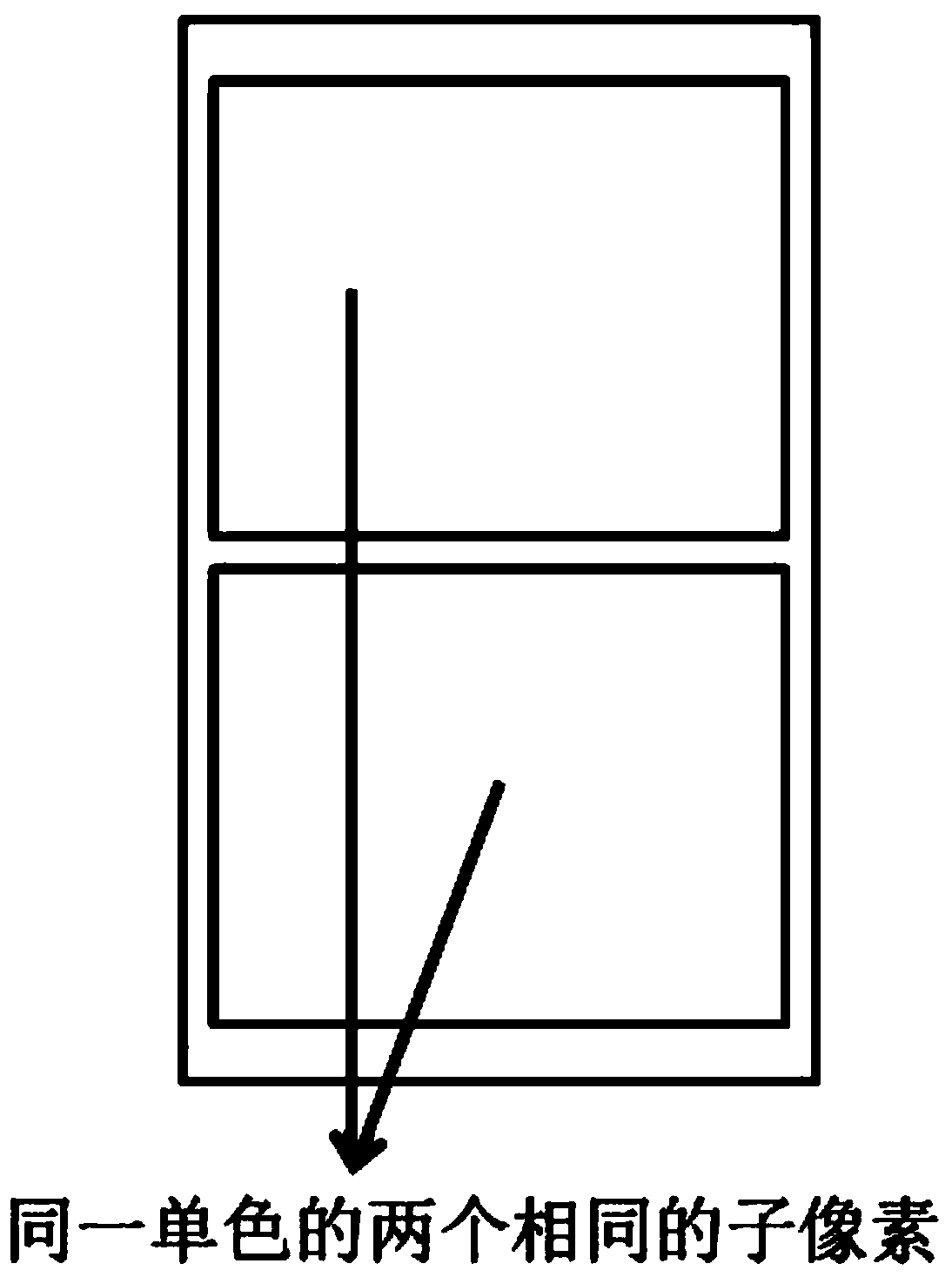

[0037] S1 regards the adjacent pixels with the same appearance and color in the pixel arrangement on the evaporation substrate as independent units;

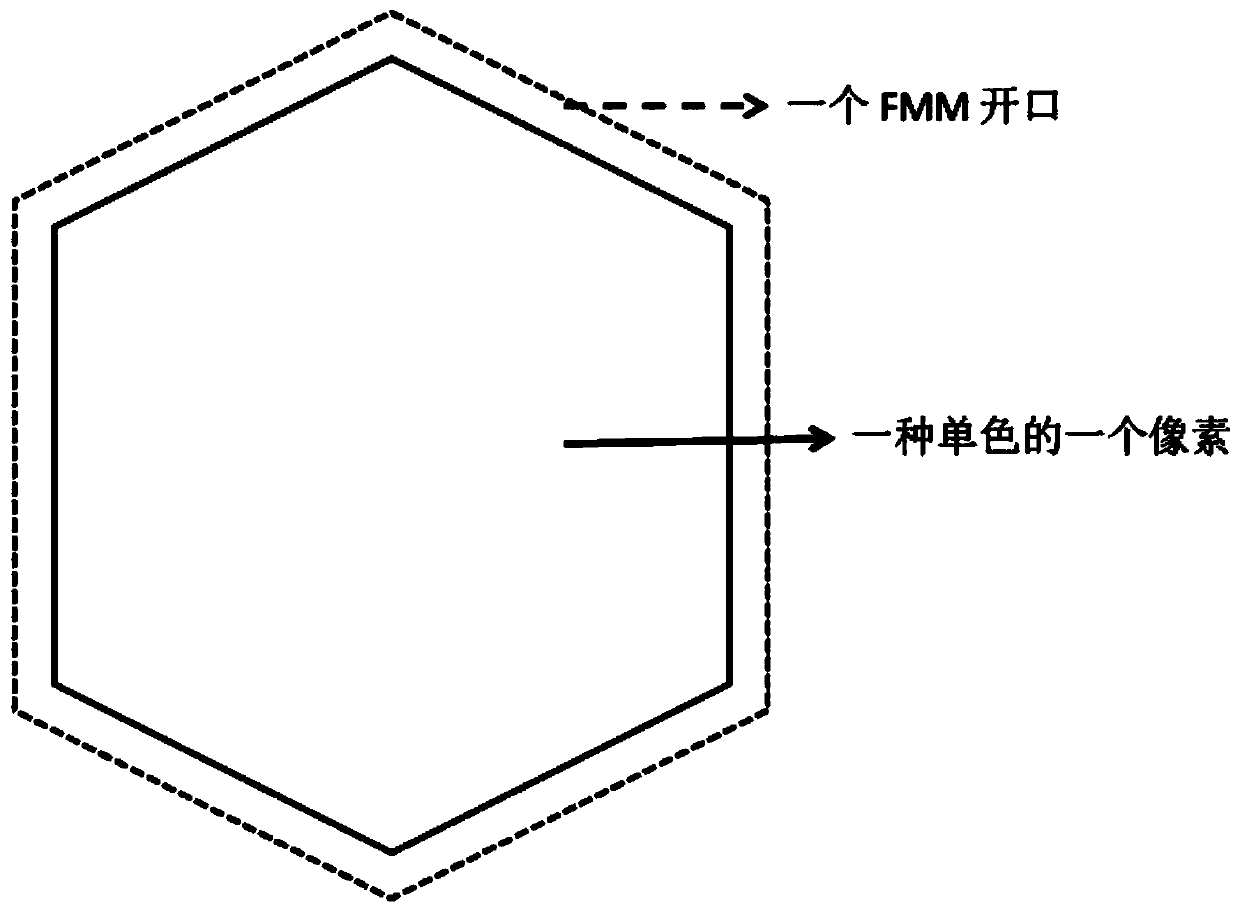

[0038] S2 opens a separate FMM opening on the evaporation substrate;

[0039] S3 uses a separate FMM opening to vapor-deposit the EL film layer to form a film for each independent unit.

[0040] When the number of pixels in the three single-color independent units is the same, all pixel arrangements and independent units are evaporated from the same FMM opening.

[0041] During the vapor deposition process, the plate with vapor deposition particles attached to the substrate closest to the vapor deposition source is removed, and a clean plate is added to the confinement unit at a position different from the removed substrate. At least one of the at least one first FM...

Embodiment 2

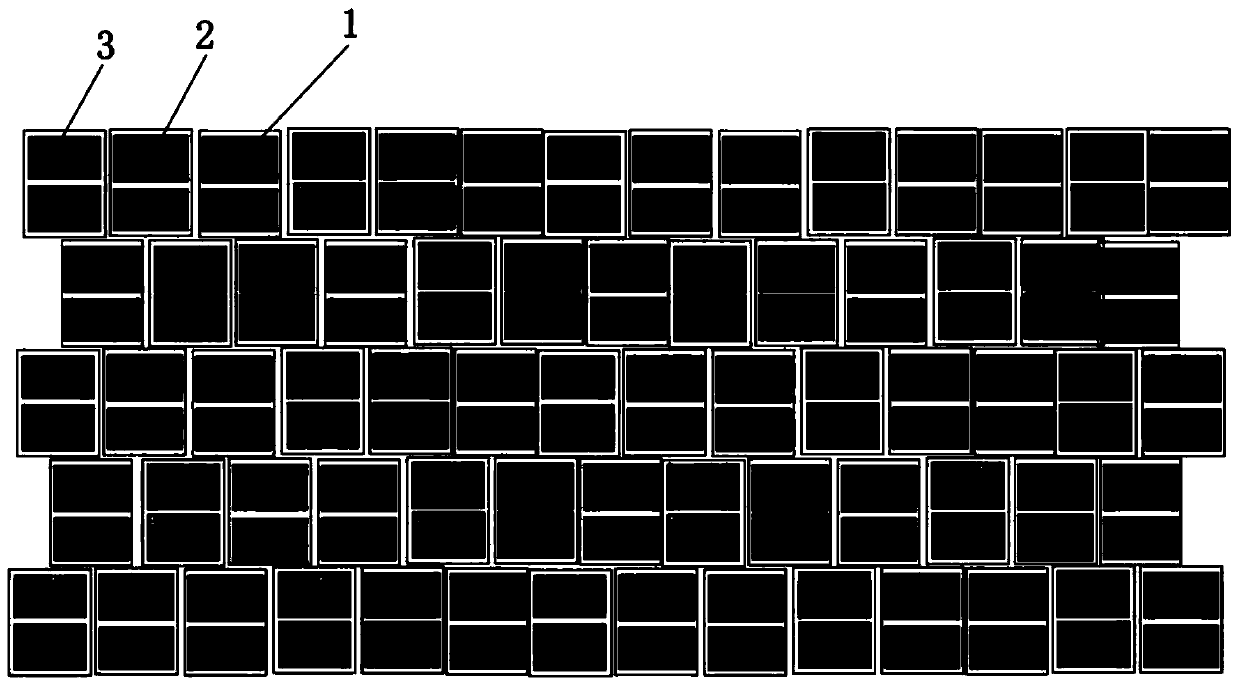

[0043] This embodiment discloses a high PPIOLED device pixel arrangement design and evaporation method, such as figure 2 shown. Its purpose is that when producing OLED screens with the same resolution, the R, G, and B pixel MASKs of the present invention are easier to process and less deformed than the existing FMM technology MASKs because the widths of the openings and connecting bridges are larger. The increase of the distance between them is beneficial to avoid color mixing and improve product yield. The evaporation alignment margin is larger, the evaporation process is easy to carry out, and the reduction in FMM replacement frequency results in increased productivity and reduced FMM cleaning loss.

[0044] In other words, when the opening width of the MASK is the same as that of the existing FMM technology, multiple types of through-holes can always be arranged on the front of the evaporation source opening so that the opening width changes as the opening of the evaporati...

Embodiment 3

[0053] This embodiment discloses a pixel arrangement display device and an evaporation method that can improve pixel resolution. R pixels, G pixels, and B pixels that can be independently controlled in quadrilateral shape and emit light are sequentially arranged on the evaporation substrate; Pixels of the same color are used as independent units, and the EL film layer is evaporated and formed into a film for each independent unit using a separate FMM opening. The material of the EL film layer can be benzyne, styrene amine, triphenylamine, porphyrin, triazole, imidazole, oxadiazole, polyaryl alkanes, phenylenediamine, arylamine, oxazole, anthracene, fluorenone , hydrazone, stilbene, triphenylene, azatriphenylene and their derivatives; polysilane compounds; heterocyclic or chain conjugated compounds such as vinyl carbazole compounds, thiophene compounds, aniline compounds, etc. monomers, oligomers or polymers, etc.

[0054] Various combinations of the types of the organic EL la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com