Functional gel as well as preparation method and application thereof

A gel and functional technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of easy water loss, high-temperature resistance of gel substrate materials, deformation and shrinkage, etc., and achieve strong wettability , The preparation process is simple and fast, and the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

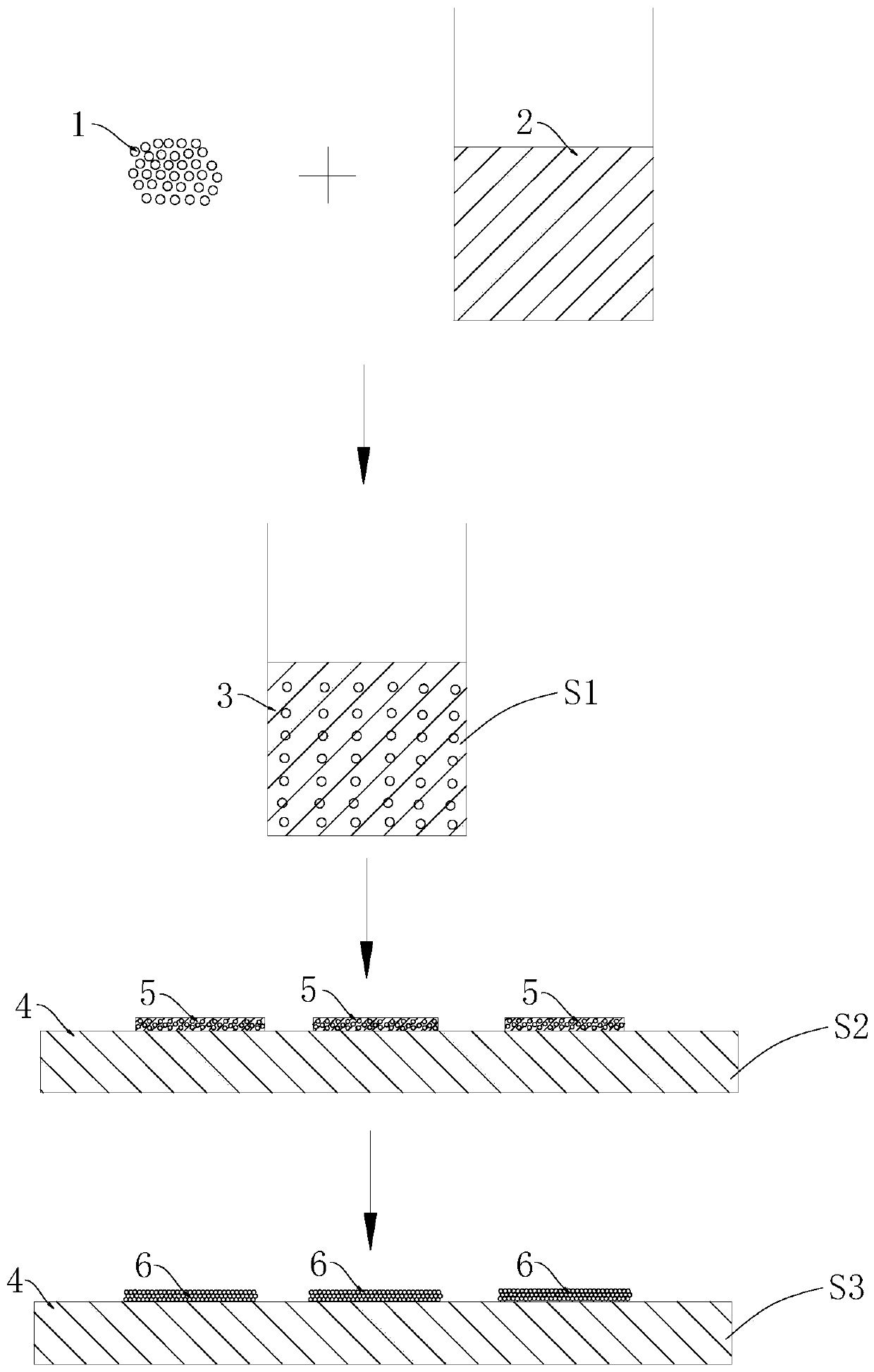

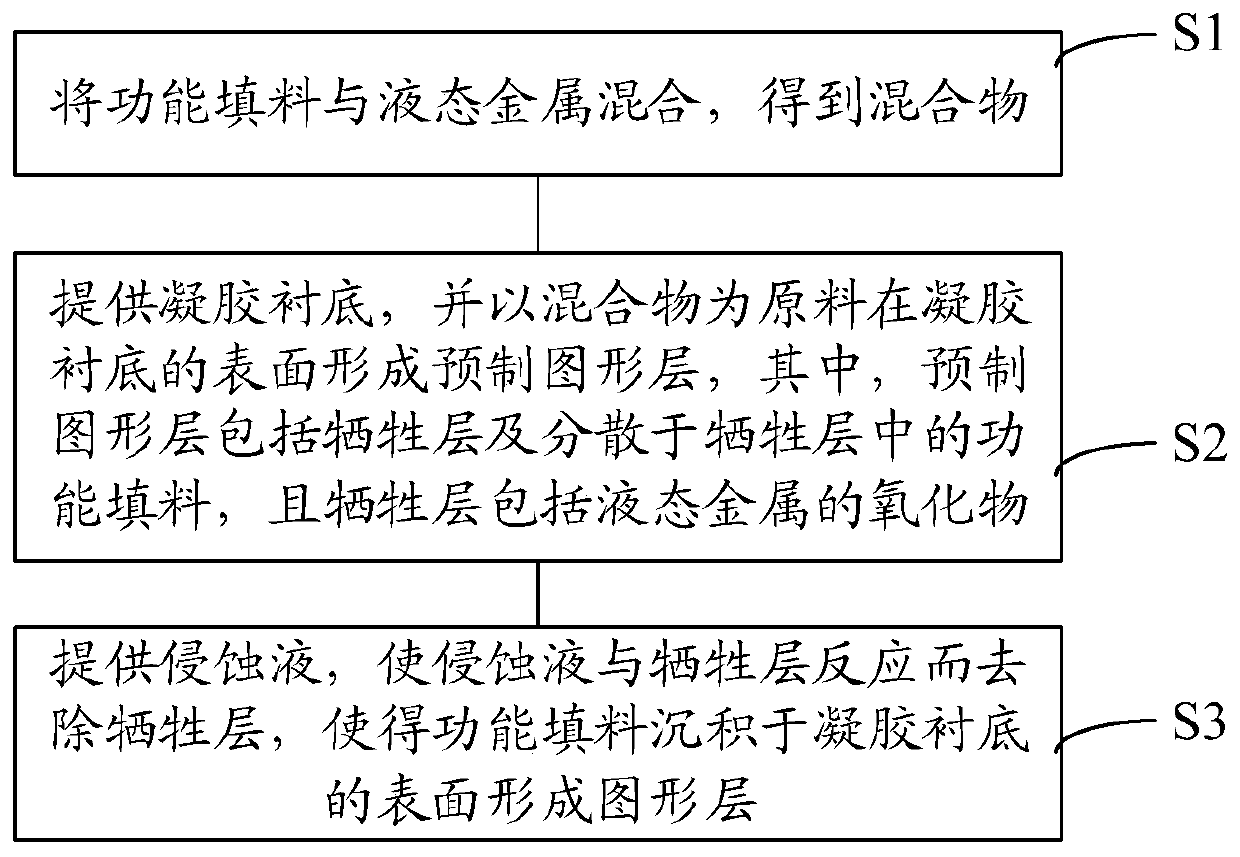

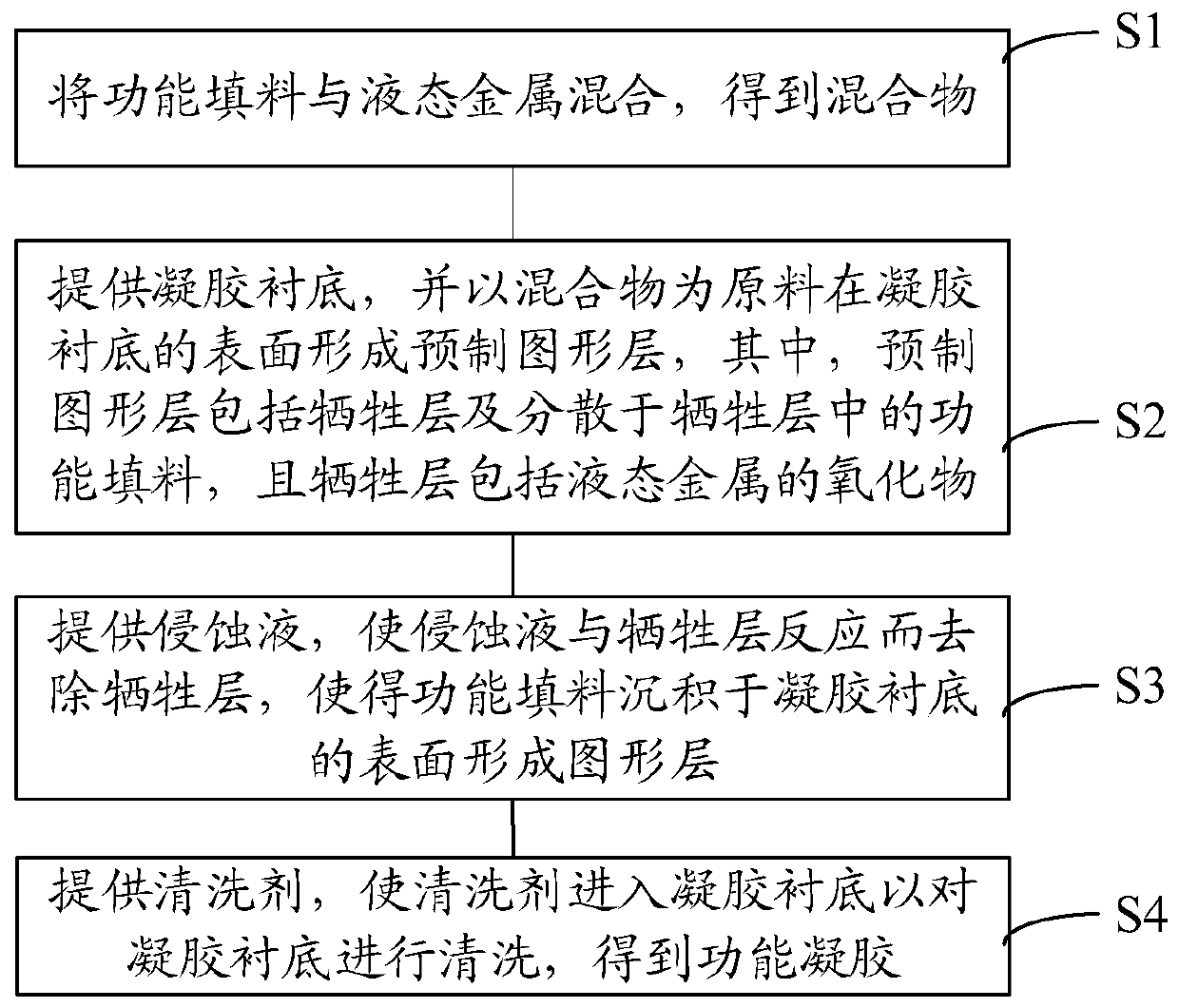

[0043] The preparation method of the functional gel specifically comprises the following steps:

[0044] S1: Mix functional filler 1 with liquid metal 2 to obtain mixture 3;

[0045] S2: Provide a gel substrate 4, and use the mixture 3 as a raw material to form a prefabricated pattern layer 5 on the surface of the gel substrate 4, wherein the prefabricated pattern layer 5 includes a sacrificial layer and is dispersed on the The functional filler 1 in the sacrificial layer, and the sacrificial layer includes the oxide of the liquid metal 2;

[0046] S3: provide an etching solution, and make the etching solution react with the sacrificial layer to remove the sacrificial layer, so that the functional filler 1 is deposited on the surface of the gel substrate 4 to form a pattern layer 6, and a functional gel is obtained. glue.

[0047] For traditional flexible and stretchable sensors, liquid metal 2 is used as the flexible electrode to realize conformal integration with the flexi...

Embodiment 1

[0097] (1) Put 100 parts by weight of liquid metal EGaIn (gallium indium eutectic) into a glove box, fill the glove box with inert gas Ar, and disperse 0.1 parts by weight of gold microparticles in the liquid metal EGaIn to form a mixture, And continue to stir for 1 hour in an inert gas atmosphere, so that the gold microparticles are monodispersed in the liquid metal EGaIn, and the diameter of the gold microparticles is approximately 20 μm;

[0098] (2) A methacrylic anhydride-based gelatin substrate is provided, and the above mixture is used as a 3D printing slurry, and the mixture is drawn on the top surface of the methacrylic anhydride-based gelatin substrate by a 3D printer nozzle;

[0099] (3) Oxidize the liquid metal EGaIn on the surface of the gel substrate, place it under natural conditions (in the air), and heat it at a temperature of 60°C for 20min, so that the surface of the gel substrate is in contact with the air The liquid metal EGaIn undergoes an oxidation react...

Embodiment 2

[0104] (1) Put 100 parts by weight of liquid metal GaInSn into a glove box, fill the glove box with inert gas Ar, disperse 0.5 parts by weight of graphene sheets in liquid metal GaInSn to form a mixture, and inert gas atmosphere Continue to stir for 2 hours, so that the graphene sheets are monodispersed in the liquid metal GaInSn;

[0105] (2) Place the above mixture under oxygen-enriched conditions and heat it at 60°C for 2 minutes to cause the liquid metal GaInSn to oxidize, and the mass ratio of the liquid metal GaInSn oxide to the liquid metal GaInSn is 2:100;

[0106] (3) polyacrylamide-based gel substrate is provided, and the mixture is used as a 3D printing slurry, and the mixture is drawn on the top surface of the polyacrylamide-based gel substrate by a 3D printer nozzle;

[0107] (4) Immerse the bottom surface of the gel substrate in the dilute sulfuric acid solution for 1 hour, so that the dilute sulfuric acid solution slowly consumes the liquid metal GaInSn and its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com