Preparation and application of hydrophobic Schiff base cobalt-beta cyclodextrin-graphene porous carbon composite material

A technology of β-cyclodextrin and Schiff base cobalt, which is applied in the field of hydrophobic Schiff base cobalt@β-cyclodextrin-graphene porous carbon composite materials and its preparation, can solve the problem that cobalt oxide cannot be anchored in it, and cannot Solve the problems of agglomeration and not significantly improve the specific capacitance of electrode materials, achieve the effect of multiple active sites, low price, and avoid agglomeration of cobalt oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

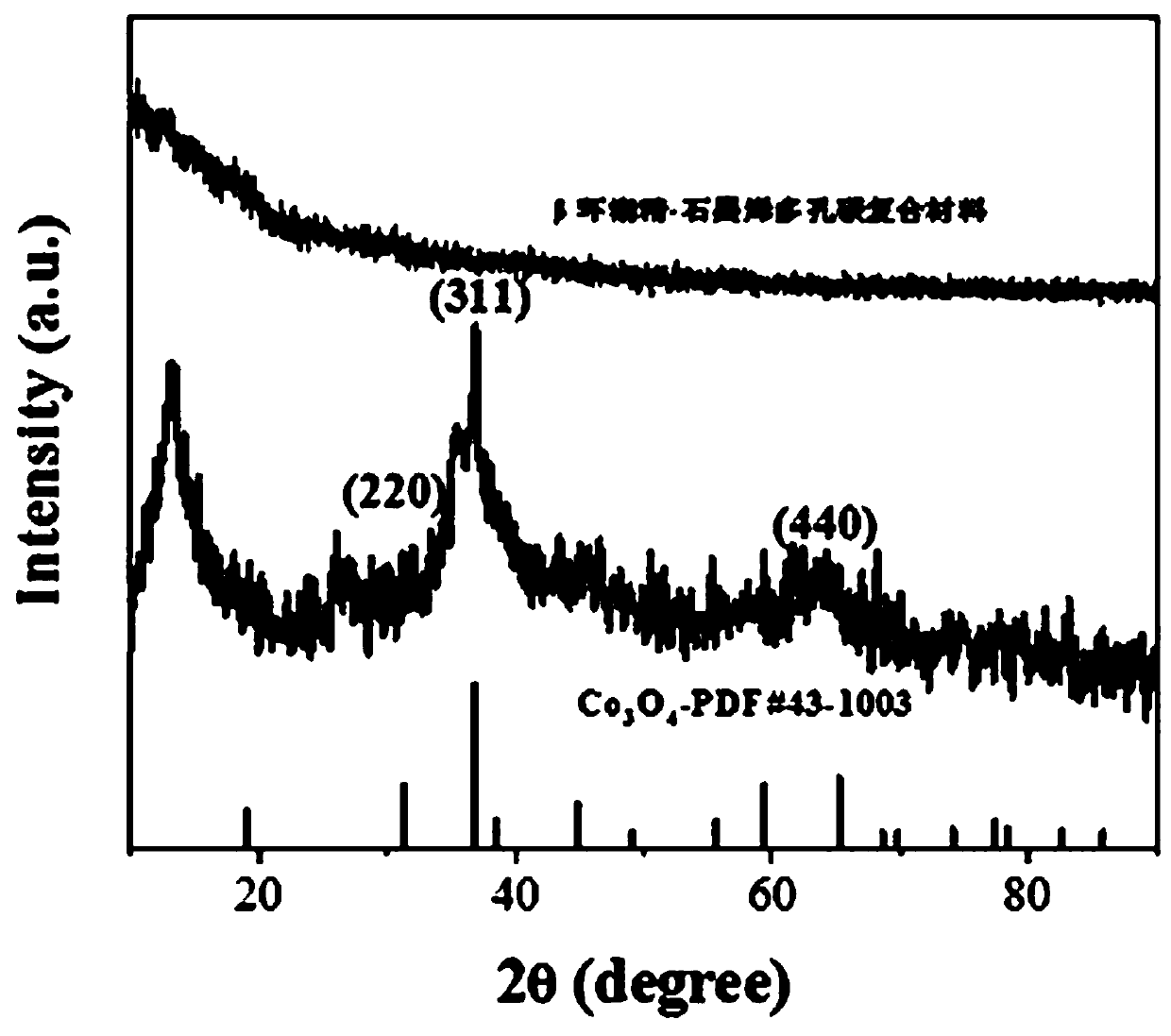

[0037] A method for preparing a hydrophobic Schiff base cobalt@β cyclodextrin-graphene porous carbon composite material, comprising the following steps:

[0038] 1) Preparation of 5-chlorosalicylaldehyde dicyandiamide Schiff base cobalt, dissolving dicyandiamine, 5-chlorosalicylaldehyde, and cobalt acetate tetrahydrate in 5ml with a mass ratio of 0.4204:1.57:1.254 , 20ml and 5ml of methanol solution to prepare dicyandiamine solution, 5-chlorosalicylaldehyde solution and cobalt acetate tetrahydrate solution, then mix the three solutions evenly and carry out hydrothermal reaction at 120°C for 12h, after the reaction is completed After filtering, washing and drying, black solid powder 5-chlorosalicylaldehyde dicyandiamide Schiff base cobalt was obtained;

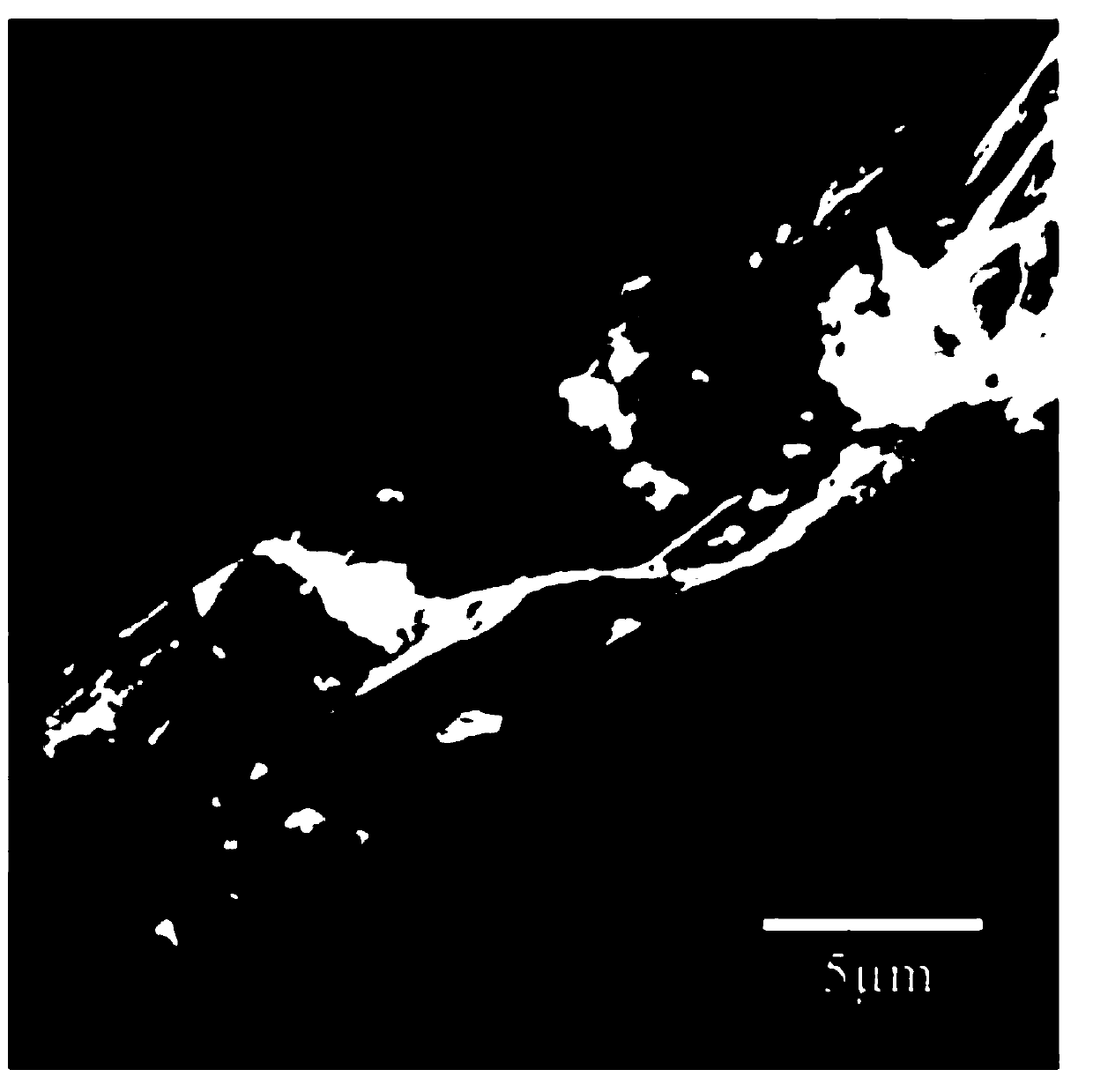

[0039] 2), the preparation of the hydrophobic Schiff base cobalt-β-cyclodextrin-graphene, with a volume ratio of 2:1, deionized water and ethanol are prepared as a mixed solvent, and then the mass ratio of 2:5.67:0.005 is the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com