Power device active junction temperature control system and method

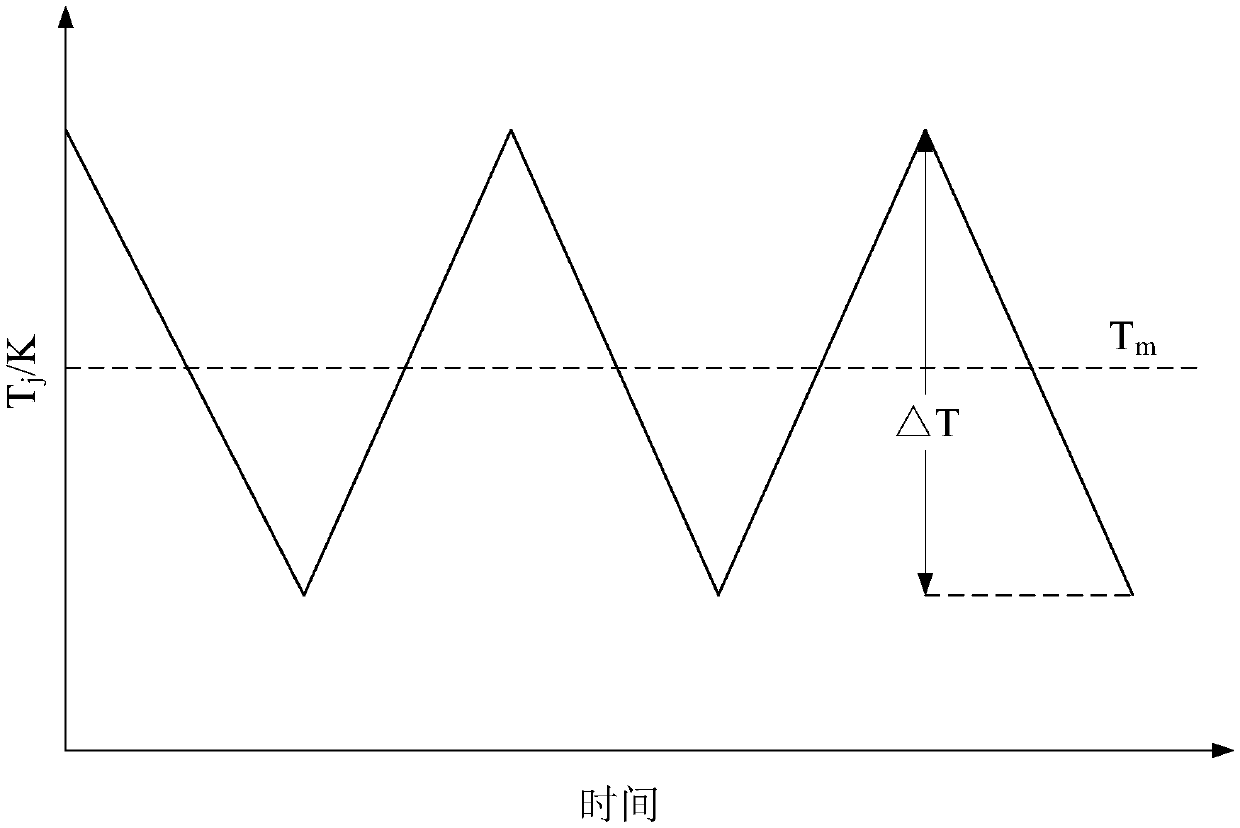

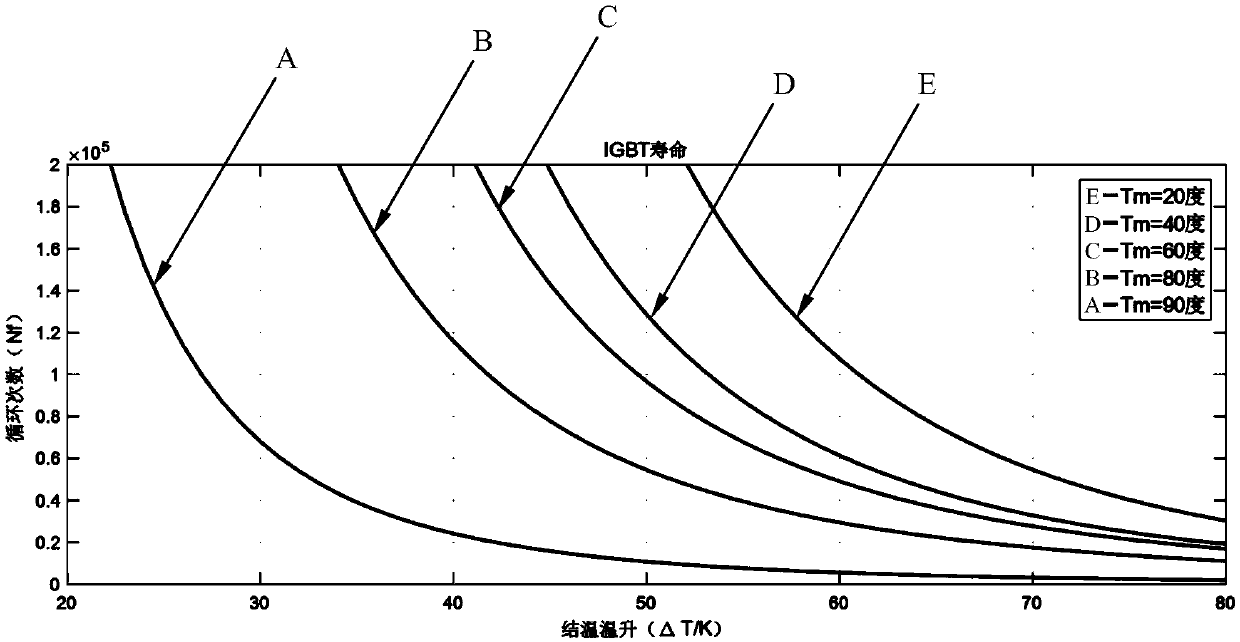

A technology for power devices and control systems, applied in the field of active junction temperature control systems for power devices, can solve the problems of reduced reliability and life of converters, high average junction temperature levels of power devices, and excessive junction temperature fluctuation amplitudes. , to achieve the effect of short adjustment time, optimized control strategy, and reduced junction temperature fluctuation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

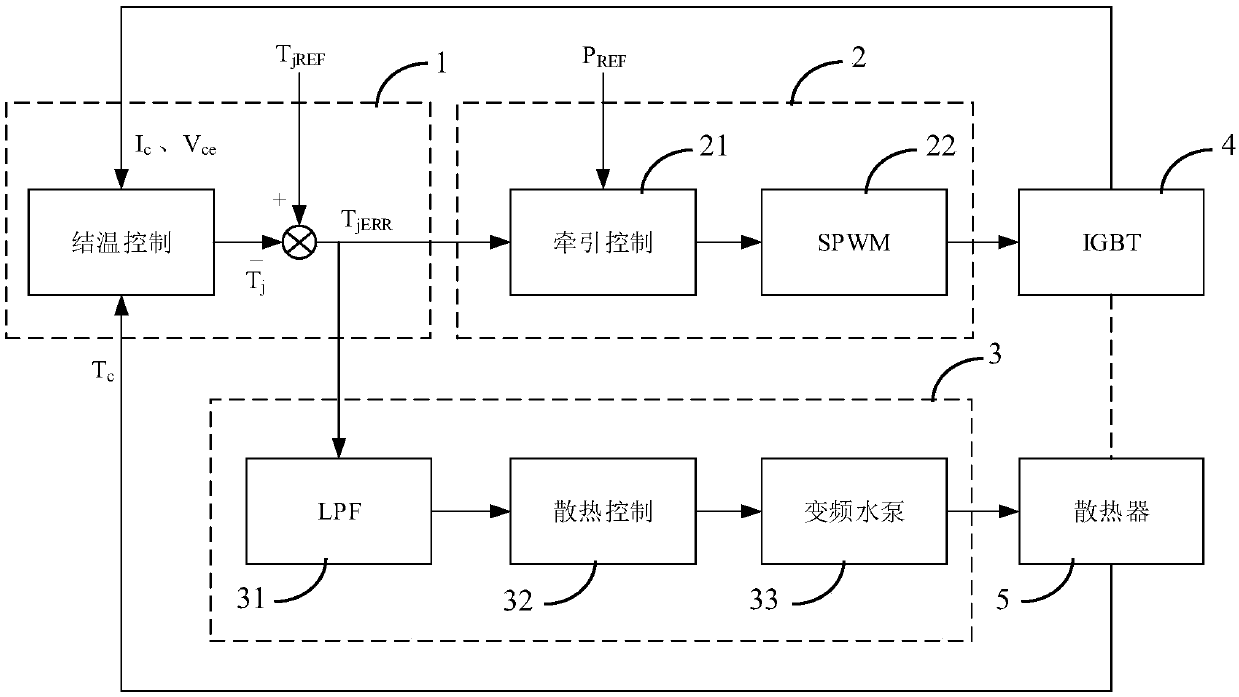

[0049] via as attached image 3 The embodiment shown, to reduce the junction temperature fluctuation amplitude ΔT and the average junction temperature T m controlled within a reasonable range. An active junction temperature control system for a power device, specifically comprising: a junction temperature control unit 1 , a junction temperature control link 2 , a case temperature control link 3 , a power device 4 and a radiator 5 . The junction temperature control unit 1 is based on the real-time junction temperature T of the power device 4 j with a given junction temperature T jREF The difference T jERR Calculate and output the control quantity to the crust temperature control link 2 and the shell temperature control link 3. The junction temperature control link 2 is based on the real-time junction temperature T of the power device 4 j with a given junction temperature T jREF The difference T jERR and traction control input signal P REF Calculate the traction control ...

Embodiment 2

[0055]as attached Figure 4 As shown, an embodiment of a method for active junction temperature control of a power device specifically includes the following steps:

[0056] S11) According to the real-time junction temperature T of the power device 4 j with a given junction temperature T jREF The difference T jERR and traction control input signal P REF Calculate the traction control signal output to the power device 4, by calculating the temperature T between the junction and the case of the power device 4 during operation jc Perform active control to reduce the average junction temperature T of the power device 4 m and junction temperature fluctuation amplitude △T j ;

[0057] S12) According to the real-time junction temperature T of the power device 4 j with a given junction temperature T jREF The difference T jERR Calculate the control value output to the frequency conversion water pump 33, actively control the thermal resistance of the radiator 5 by adjusting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com