Liquid surface tension coefficient measuring method

A technology of liquid surface tension and measurement method, applied in surface tension analysis and other directions, can solve the problems of inconvenient measurement and inaccurate measurement, and achieve the effect of simple and accurate measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

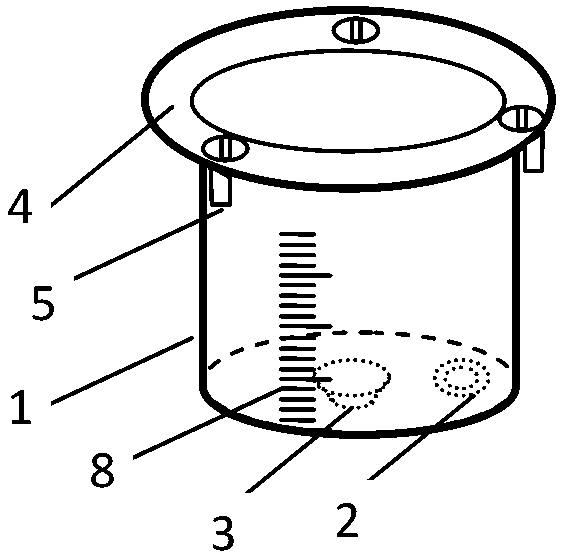

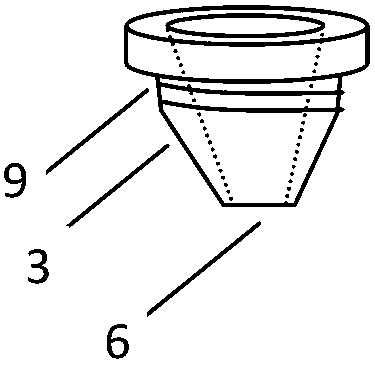

[0011] According to the method of measuring the surface tension coefficient of the liquid by the drop weight method, the relationship between the mass m of the droplet and the diameter d of the dropper (the outer diameter if it is infiltrated, and the inner diameter if it is not infiltrated) satisfies m*g=π*d*σ , that is, σ=m*g / (π*d); the existing problem is: when the liquid breaks into droplets, part of the liquid will shrink back, causing the mass m of the dripping droplets to decrease, which requires correction, and also As a result, the measurement method is inconvenient and even difficult to understand.

[0012] The present invention discusses this problem from another angle. The dripping of the liquid is caused by the insufficient surface tension of the liquid to hold the liquid, that is, the pressure (pressure) of the liquid column. Therefore, we discuss it from the perspective of pressure. : Liquid has surface tension on the upper surface of the container and the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com