Sensor for three-floated gyroscope and stator preparation process thereof

A sensor rotor and sensor technology, applied in the field of sensors, can solve problems such as magnetic circuit asymmetry, achieve the effects of reducing assembly errors, not easily deformed and cracked, and solving eddy current problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

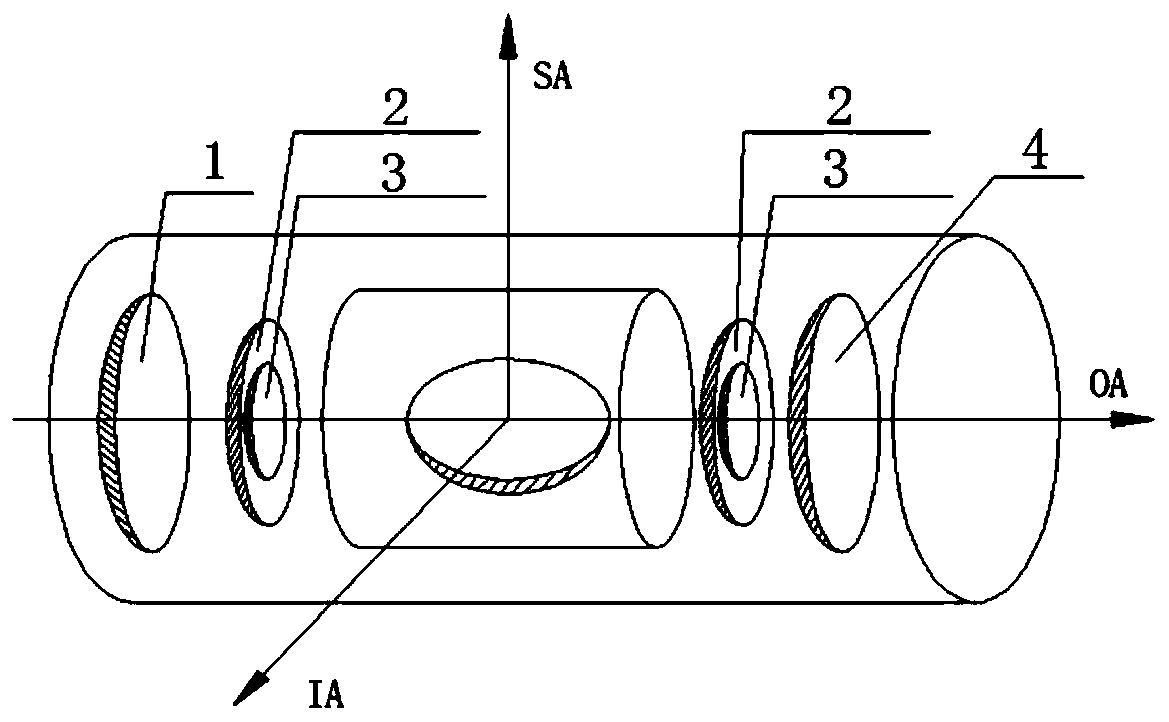

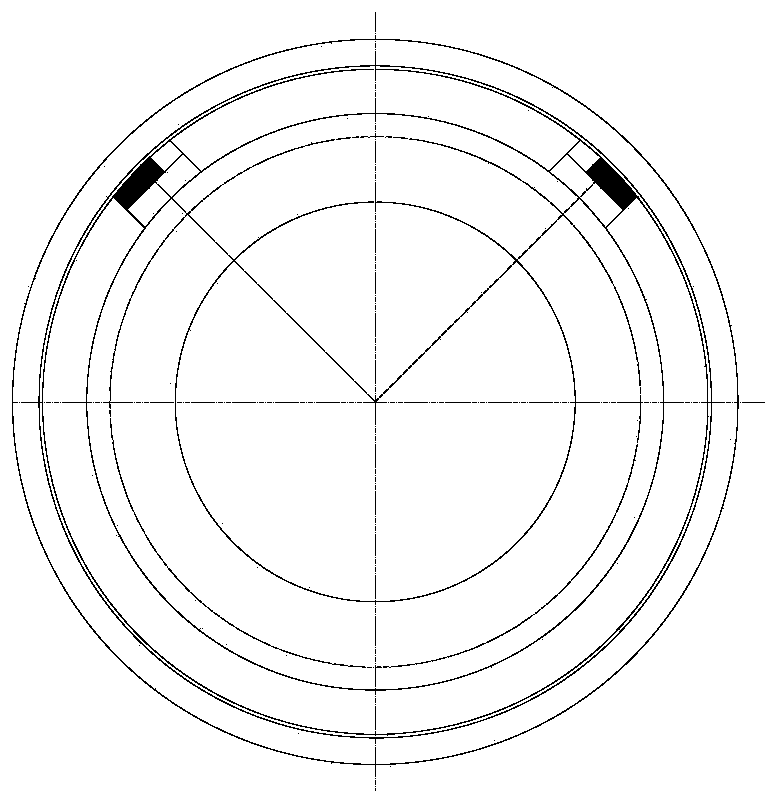

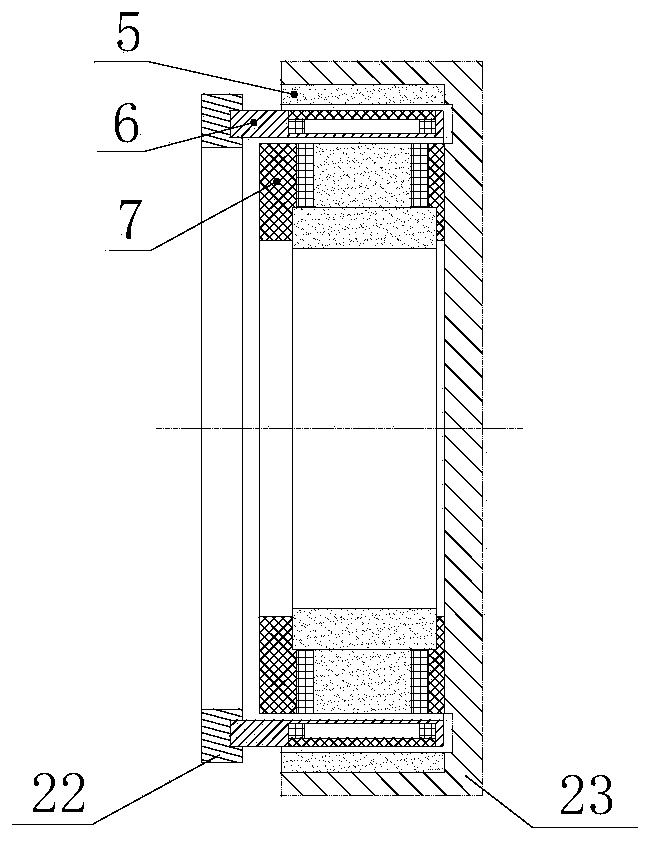

[0053] Such as Figure 5 and Image 6 As shown, the sensor structure for the three-float gyroscope of the present invention is arranged coaxially with the outer magnetic ring 5, the sensor rotor 6, and the sensor stator 7 in sequence from the outside to the inside, and the three together form an angular displacement sensing system of the sensitive float relative to the gyro end cover . The outer magnetic ring 5, the sensor stator 7 and the gyroscope end cover 23 are bonded together and fixed, and the sensor rotor 6 is bonded on the float frame.

[0054] The sensor rotor of the present invention includes 1 rotor bracket 16, 4 rotor coils 11, 2 lugs 12, rotor potting glue layer 8 and other parts and auxiliary items; the stator includes 1 inner magnetic ring 20, 8 stator poles, 8 stator coils 19 and stator potting glue layer 17 and other parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com