Radiation cross-linked polyethylene heat shrinkable wrap and preparation method thereof

A radiation cross-linking, heat shrinkable tape technology, applied in the direction of heat activated films/sheets, mineral oil hydrocarbon copolymer adhesives, unsaturated ether copolymer adhesives, etc. It can improve the low temperature bonding performance, high bonding force and excellent low temperature bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

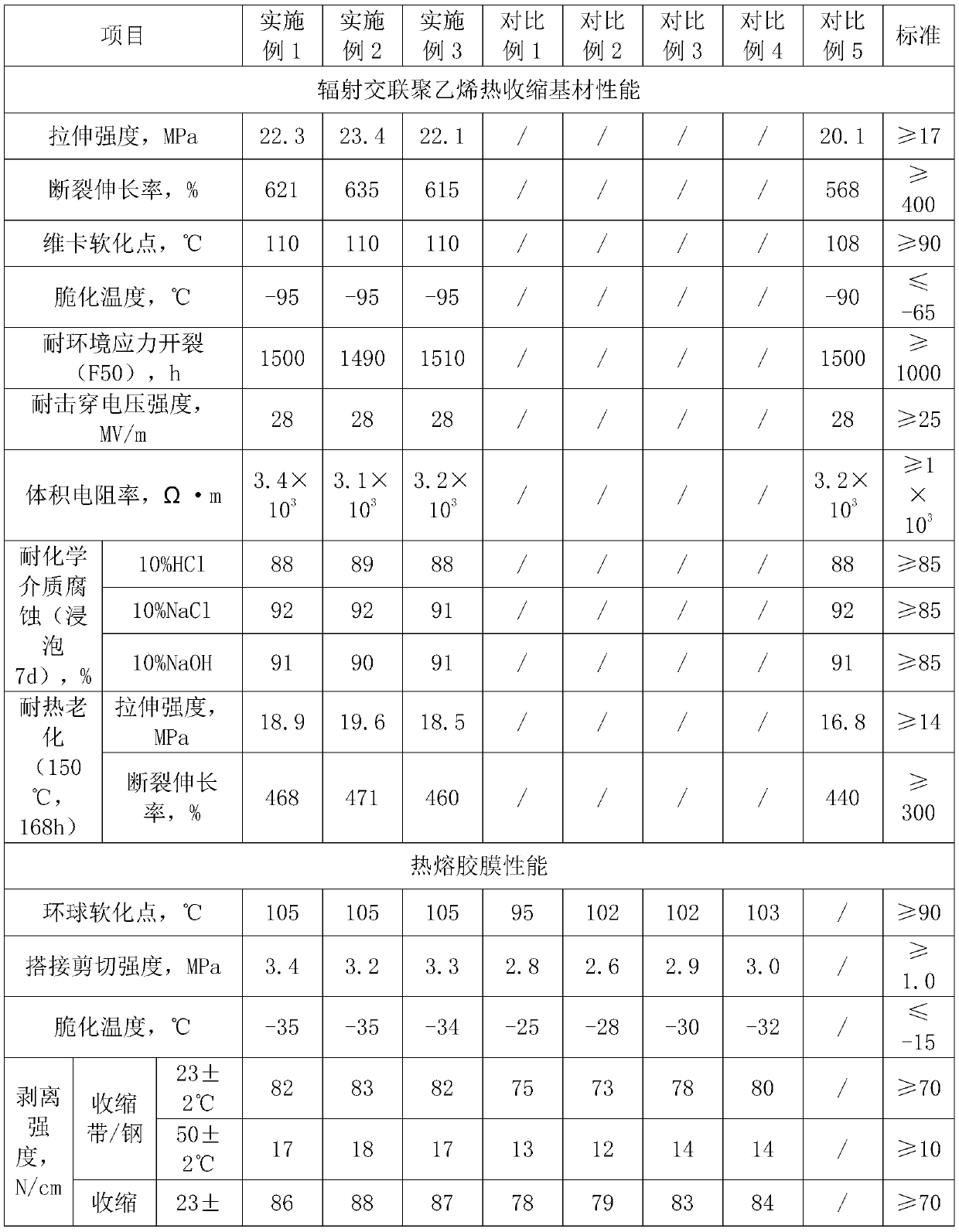

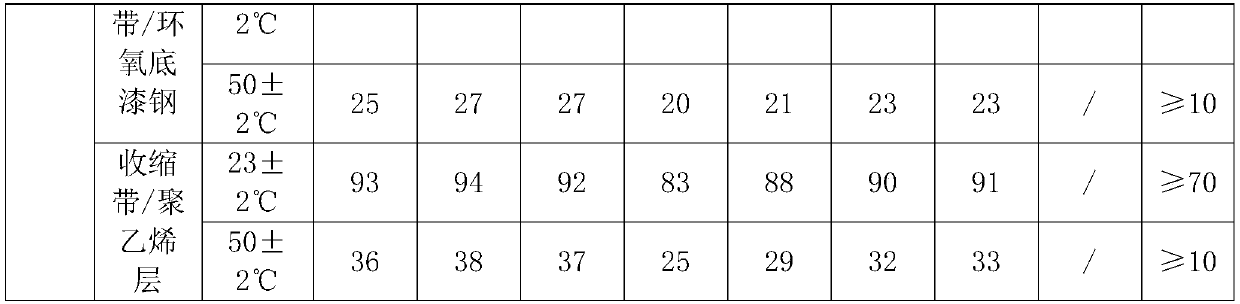

Examples

preparation example 1

[0034] Preparation Example 1 of Modified Pottery Clay: ①Add 50% of its weight to the pottery clay with 10wt% dilute hydrochloric acid solution, soak it for 2 hours, then rinse it with deionized water until the pH value of the rinse solution is 7, then put the acidified The potter's clay was dried at a temperature of 120°C for 6 hours to obtain acidified pottery clay;

[0035]②Add 4% ethyl cellulose, 3% ethylene glycol dimethacrylate, 3% sodium lignosulfonate, 1% polyvinylpyrrolidone, 0.1% aminopropyl to the acidified clay Trimethoxysilane was dispersed at a high speed of 1000r / min for 10 minutes, kept at a temperature of 110°C for 40 minutes, and cooled to 20°C to obtain modified clay.

preparation example 2

[0036] Preparation Example 2 of Modified Pottery Clay: 1. Add 50% of its weight to the pottery clay with 10wt% dilute hydrochloric acid solution, soak it for 2.5h, then rinse it with deionized water until the pH value of the rinse solution is 7, then acidify The final potter's clay was dried at a temperature of 120° C. for 6 hours to obtain acidified pottery clay;

[0037] ② Add 6% ethyl cellulose, 4% ethylene glycol dimethacrylate, 4% sodium lignosulfonate, 1.5% polyvinylpyrrolidone, 0.25% aminopropyl to the acidified clay Trimethoxysilane was dispersed at a speed of 1000r / min for 15 minutes, kept at a temperature of 115°C for 50 minutes, and cooled to 20°C to obtain modified clay.

preparation example 3

[0038] Preparation Example 3 of Modified Pottery Clay: ① Add 50% of its weight to the pottery clay with a 10wt% dilute hydrochloric acid solution, soak it for 3 hours, then rinse it with deionized water until the pH value of the rinse solution is 7, then acidify the clay The potter's clay was dried at a temperature of 120°C for 6 hours to obtain acidified pottery clay;

[0039] ②Add 8% ethyl cellulose, 5% ethylene glycol dimethacrylate, 5% sodium lignosulfonate, 2% polyvinylpyrrolidone, 0.4% aminopropyl to the acidified clay Trimethoxysilane was dispersed at a high speed of 1000r / min for 20 minutes, kept at a temperature of 120°C for 60 minutes, and cooled to 20°C to obtain modified clay.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com