Efficient self-healing agent for ultrahigh-temperature oil well cement based on crack response and application threof

An oil well cement and ultra-high temperature technology, which is applied in the field of oil drilling and cementing, can solve problems such as mechanical defects, low resin strength, and poor temperature resistance, and achieve the effects of small environmental dependence, small mechanical properties, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Microencapsulated epoxy resins are prepared by:

[0027] Under stirring at 250r / min, add 20g of epoxy resin E44 and 20g of n-butyl glycidyl ether to 100g of distilled water, stir evenly; add 0.2g of Tween 60 and 1g of sodium dodecylbenzenesulfonate, stir and mix well, Obtain emulsion, under nitrogen atmosphere, put 24g styrene and 3g divinylbenzene into described emulsion, mix, be warming up to 60 ℃, add the benzoyl peroxide equivalent to epoxy resin E44 quality 0.5%, Raise the temperature to 80° C., react for 1 h; wash with acetone twice, deionized water twice, filter with suction, and dry to obtain a microencapsulated epoxy resin.

Embodiment 2

[0029] A high-efficiency self-healing agent for ultra-high temperature oil well cement based on fracture response, including microencapsulated epoxy resin (prepared in Example 1) and dicyandiamide with a mass ratio of 6:0.4.

[0030] The application of present embodiment self-healing agent:

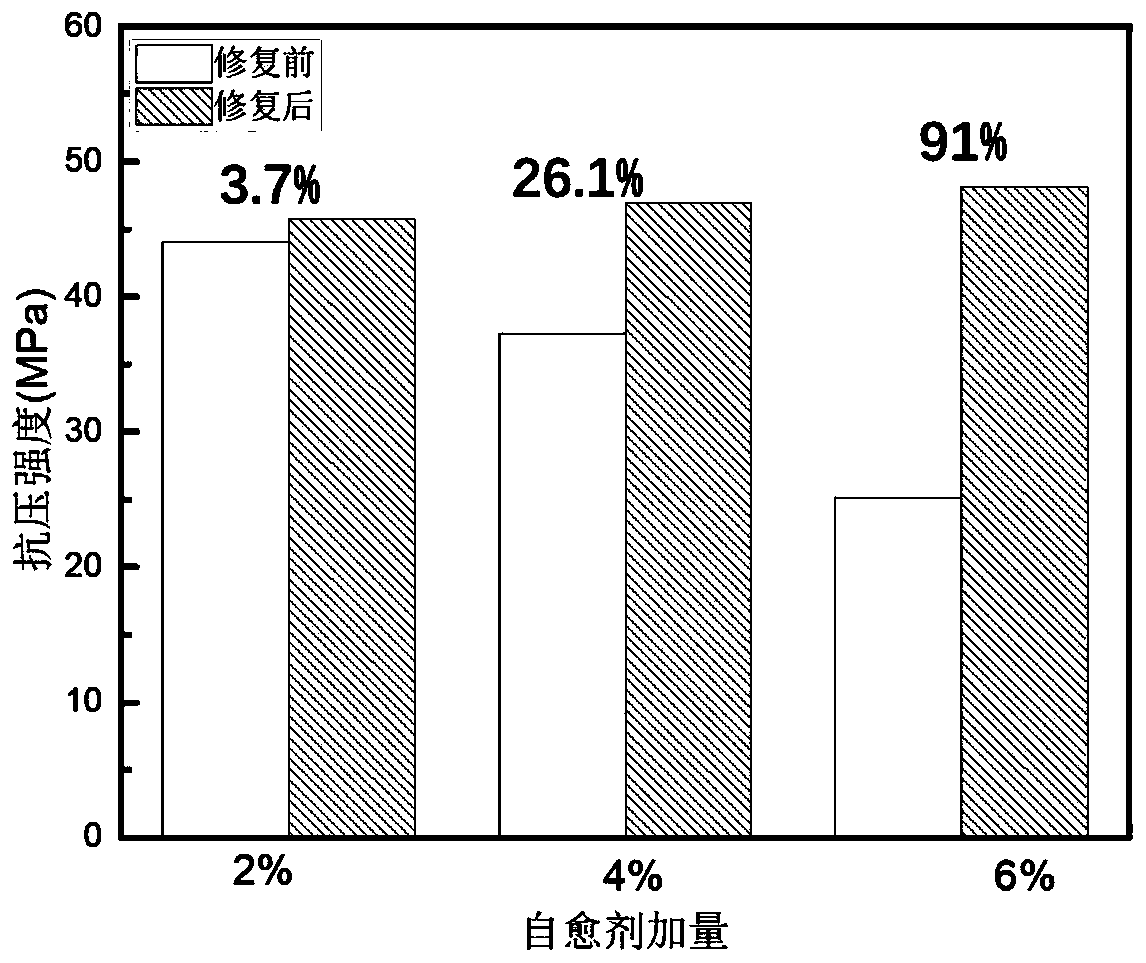

[0031] Add 2%, 4%, and 6% self-healing agents of Jiahua G-grade oil well cement to 500g Jiahua G-grade oil well cement powder respectively, add water according to the water-cement mass ratio of 0.44, mix the slurry evenly, and then maintain it for 7 days to obtain cement blocks compressive strength see image 3 before the repair. Cracks were obtained by pre-compressing with 80% force, and then cured at 150°C (ultra-high temperature) for 7 hours to repair the cracks. See the compressive strength after repairing with different amounts of self-healing agent image 3 after repair.

Embodiment 3

[0033] Microencapsulated epoxy resins are prepared by:

[0034] Stir at 150r / min, 250r / min, and 350r / min respectively, add 30g of epoxy resin E51 and 35g of benzyl alcohol into 100g of distilled water, stir well; add 0.6g of Span 80 and 1.8g of dodecylsulfuric acid Sodium, stirred and mixed to obtain an emulsion, under a nitrogen atmosphere, put 38g of styrene and 4.8g of divinylbenzene into the emulsion, mixed, heated to 60°C, and added 1% by mass of epoxy resin E51 benzoyl peroxide, heated to 70°C, and reacted for 3 hours; washed with acetone twice, deionized water twice, suction filtered, and dried to obtain microencapsulated epoxy resin, see figure 1 .

[0035] figure 1 For the optical micrograph of the microencapsulated epoxy resin prepared in this embodiment 1, under the conditions of 150r / min, 250r / min, and 350r / min respectively at the stirring speed, the microencapsulated epoxy resin obtained is respectively figure 1 a. figure 1 b and figure 1 c, by figure 1 It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com